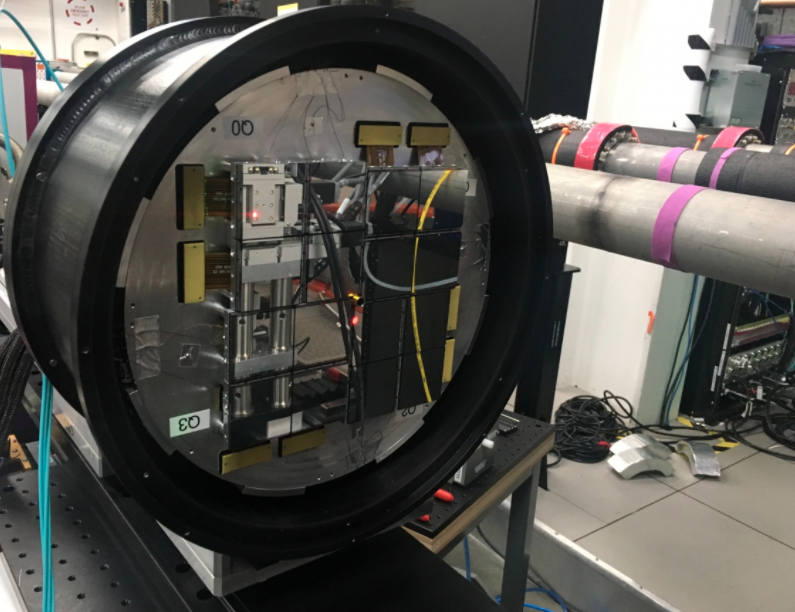

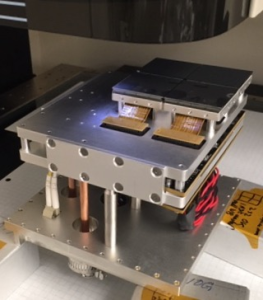

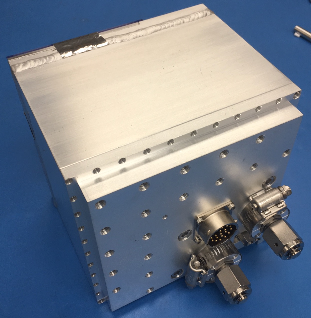

Two new detectors EPIX10KA2M and EPIX10KAQUAD are composed from EPIX10KA modules.

Content

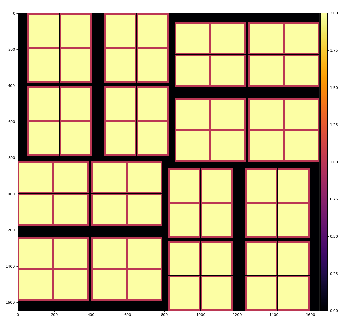

Geometry

Plots and comments from Chris Kenny

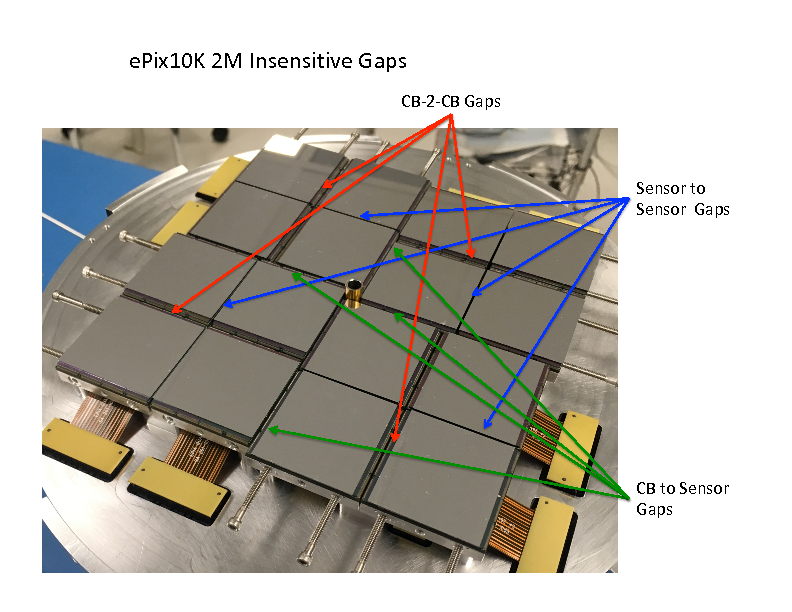

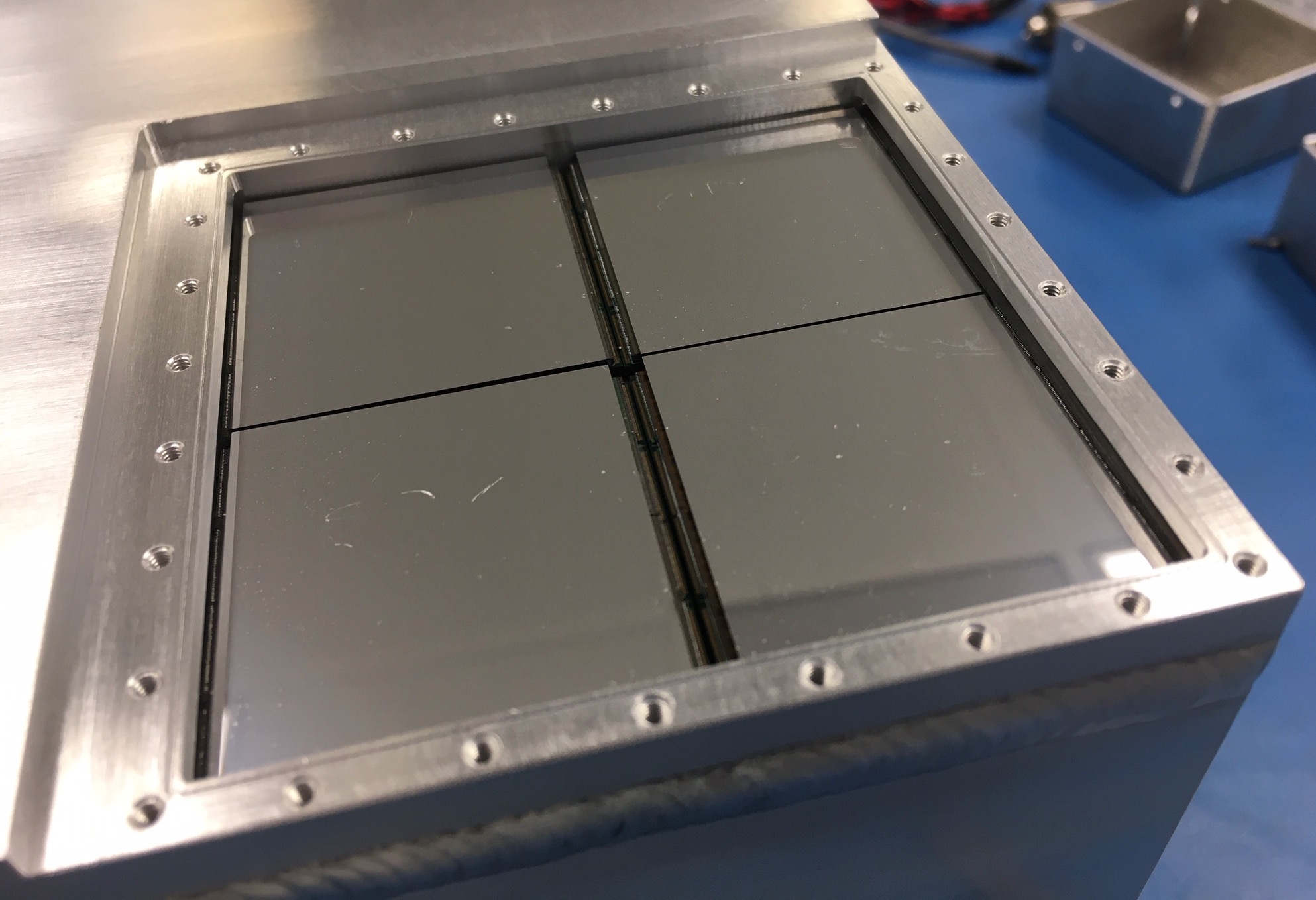

Kenney, Christopher J. 2018-11-12, 2:26 PM Guide tube is 7mm outer diameter We added polyimide tape that was 150 microns thick before application to the tube. But a decent estimate would be the mechanical edge-to-edge orthogonal separation between sensor edges 7.3 mm. We need to add about 1 mm for the guard rings on each sensor So the orthogonal gap between active pixels on opposing quads across the beam guide tube should be 8.3 mm ==== Kenney, Christopher J. 2018-11-12, 4:41 PM Blaj, Gabriel;Dubrovin, Mikhail;Kwiatkowski, Maciej Very rough estimate of the gaps There are 3 types of gaps All are active pixel to active pixel sensor to sensor ~ 1.6 mm CB to CB ~ 6.4 mm sensor to CB ~ 3.9 mm ==== CB = Carrier Board edges Full camera image below ==== so 384 columns parallel to the balcony (the widest dead gaps) and 352 orthogonal to the balcony (vertical direction)

epix10ka2m assembly

epix10ka2m-insensitive-gaps.pdf

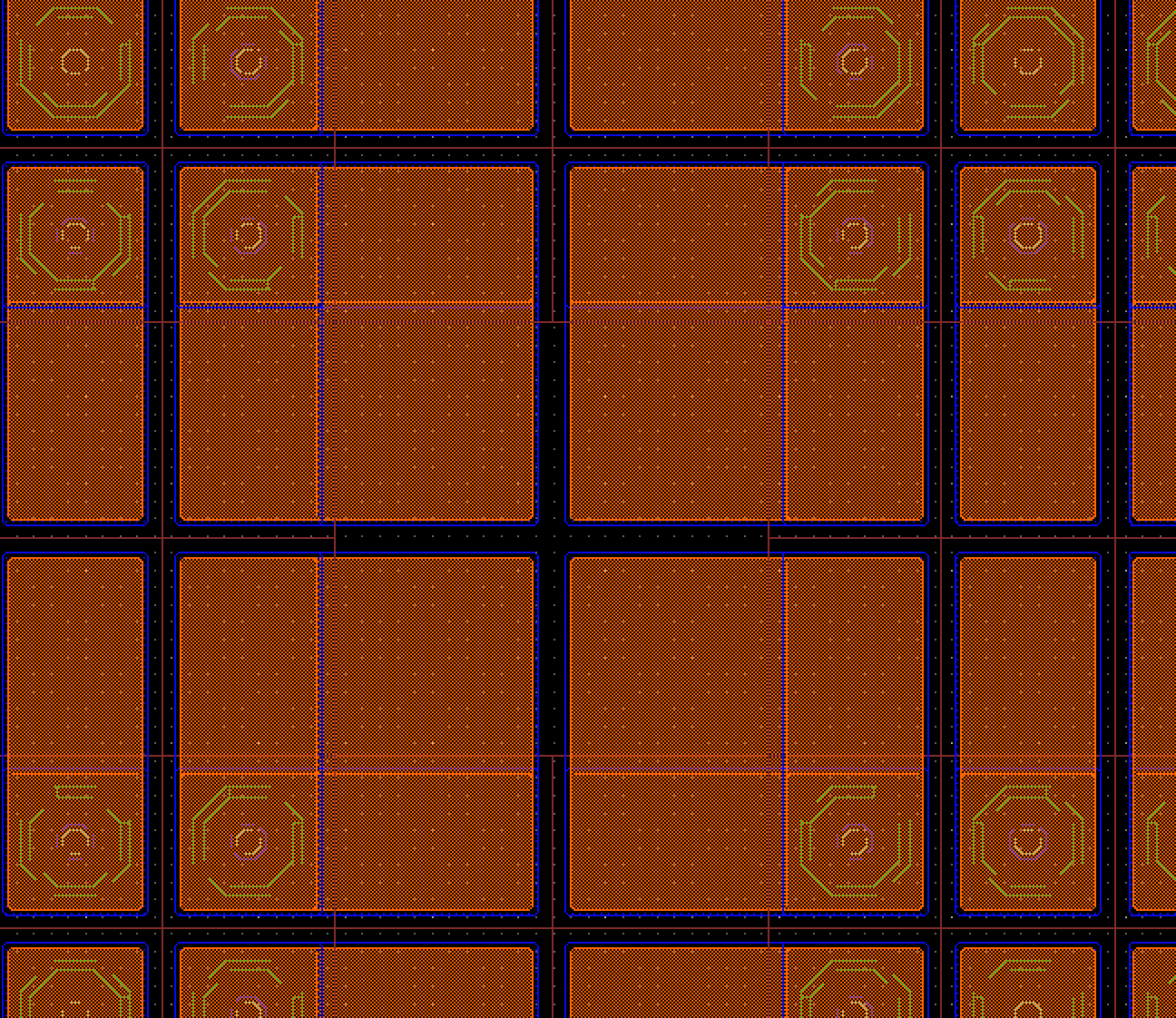

epix10ka sensor central region between 4 ASICs

The internal gap between four ASICs in sensor,

pixel size 100 x 225 microns in area in both directions.

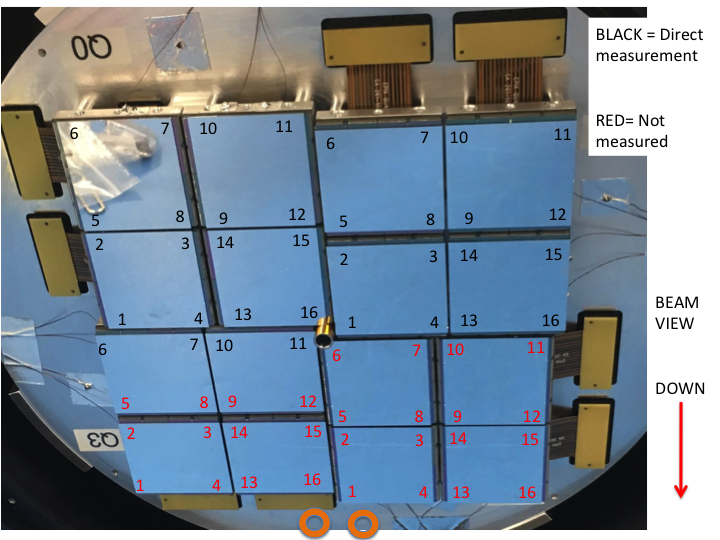

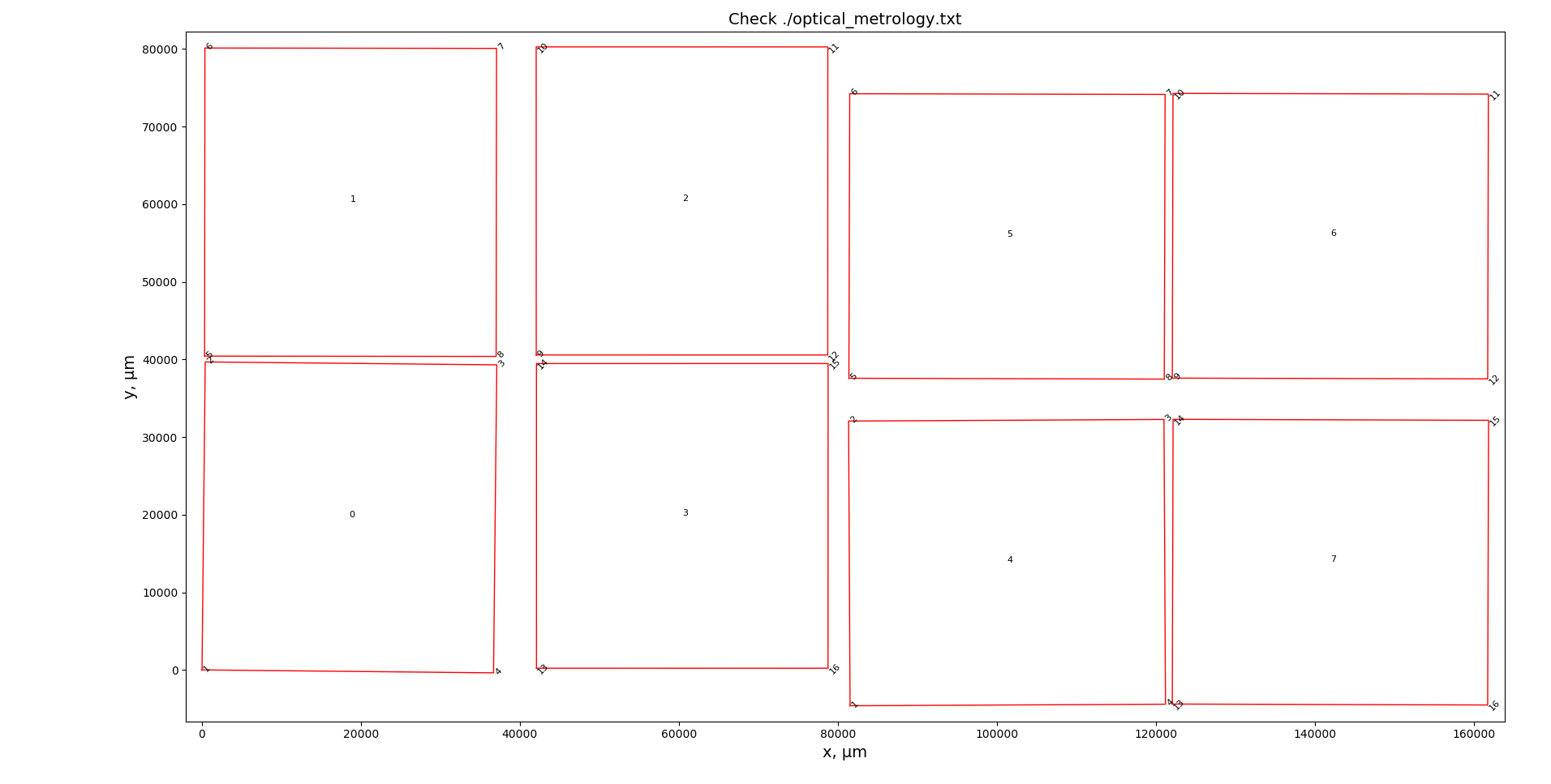

Metrology map from Chris Kenney

- 2018-11-18-epix10ka2m-metrology-map.pdf

- 2018-11-18-epix10ka2m-metrology-map.pptx

- 2018-11-15-Metrology-epix10ka2m.xlsx

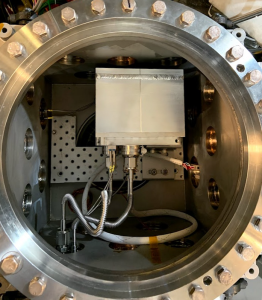

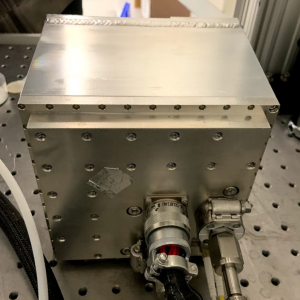

Front and back side of the new detector epix10ka2m.1 from mfxc00118 2020-07-dd

2020-10-04 MEC epix10kaquad 0 at optical metrology

2020-10-06 MEC epix10kaquad 0 front and back

2021-04-10 UED epix10kaquad

Comments on orientation of epix10ka2m parts from Matt

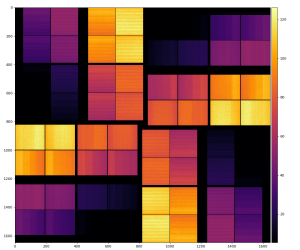

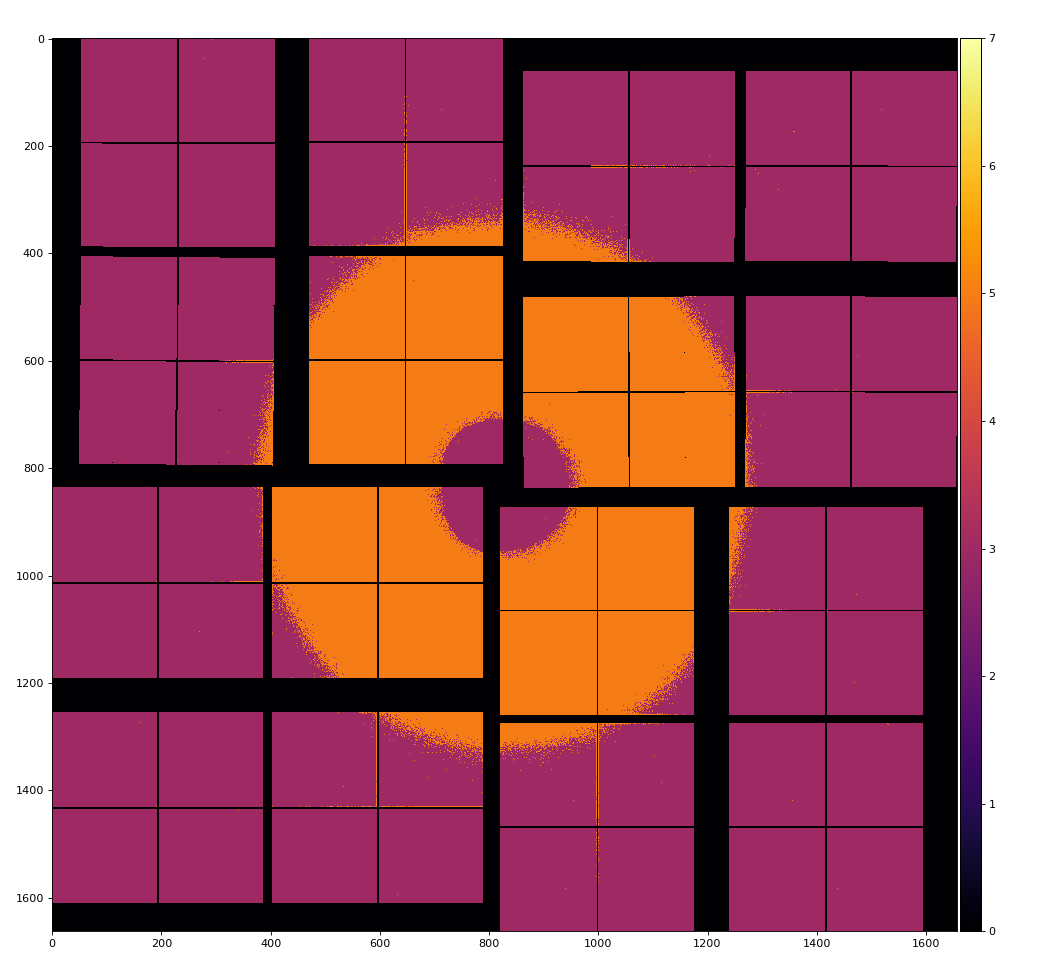

Weaver, Matt 2018-11-19, 7:37 PMO'Grady, Paul Christopher;Dubrovin, Mikhail Hi Mikhail, We took radioactive source test runs today to verify the geometry. We found that we were rotated by 90 degrees, which matches the labeling on the back of the detector as well as the metrology picture from Chris Kenney. The runs are /reg/d/psdm/det/detdaq17/e968-r0131 - source unmasked (up to ~ event 10000), then masked vertically after ~ event 15000 /reg/d/psdm/det/detdaq17/e968-r0132 - source masked horizontally at bottom after ~ event 15000. So, the picture is... // (Epix10ka2m) // | // Quad 0 | Quad 1 Quad 2 is rotated 90d clockwise // -------+-------- Quad 3 is rotated 180d clockwise // Quad 3 | Quad 2 Quad 0 is rotated 270d clockwise // | // // (Quad 1) // | // Elem 0 | Elem 1 // -------+-------- No rotations // Elem 2 | Elem 3 // | // // (Elem 0) // | // ASIC 0 | ASIC 3 // -------+-------- No rotations // ASIC 1 | ASIC 2 // | // // (Elem 0-3 pixel array) // row increasing // ^ // | // | // column increasing <-- (0,0)

Preliminary geometry

in /reg/g/psdm/detector/data_test/calib/

/reg/g/psdm/detector/data_test/calib/Epix10ka2M::CalibV1/NoDetector.0:Epix10ka2M.0/geometry/0-end.data @ (epix10ka2m - entire detector) /reg/g/psdm/detector/data_test/calib/Epix10kaQuad::CalibV1/NoDetector.0:Epix10kaQuad.0/geometry/0-end.data @ (epix10kaquad - one quad) /reg/g/psdm/detector/data_test/calib/Epix10ka::CalibV1/MecTargetChamber.0:Epix10ka.1/geometry/0-end.data @ (epix10ka - one panel)

copy of geometry files in alignment examples /reg/g/psdm/detector/alignment/

/reg/g/psdm/detector/alignment/epix10ka2m/calib/Epix10ka2M::CalibV1/NoDetector.0:Epix10ka2M.0/geometry/0-end.data /reg/g/psdm/detector/alignment/epix10kaquad/calib/Epix10kaQuad::CalibV1/NoDetector.0:Epix10kaQuad.0/geometry/0-end.data /reg/g/psdm/detector/alignment/epix10ka/calib/Epix10ka::CalibV1/MecTargetChamber.0:Epix10ka.1/geometry/0-end.data

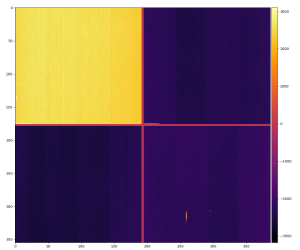

Optical metrology processing

Scripts for processing

CalibManager/app/ optical_metrology_check optical_metrology_epix10ka2m

Results in

/reg/g/psdm/detector/alignment/epix10ka2m/calib-mfx-epix10ka2m-01-2018-11-15/ 2018-11-15-Metrology-epix10ka2m.xlsx 2018-11-15-Metrology-epix10ka2m.txt 2018-11-15-Metrology-epix10ka2m-corr.txt 2018-11-15-geometry-epix10ka2m.txt - geometry file accounting for optical metrology data README-2018-11-15

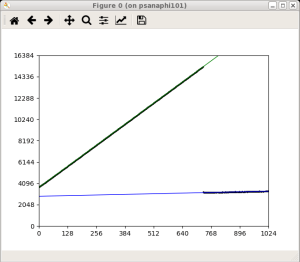

Gain

Gain factors from charge injection default and measured

| gain | charge injection | current default | measured (ADU / keV) | 2020-08-03 Gabriel (ADU / keV) - use as default |

|---|---|---|---|---|

| L | 0.46 | 0.01 | 0.139 | 0.164 |

| M | 15. | 0.3(3) | 4.5 | 5.466 |

| H | 46.7 | 1 | 13.9 | 16.40 |

Gain factors default vs charge injection

- Detector/examples/ex_epix10ka_images.py

- XcsEndstation.0:Epix10ka2M.0

- charge injection gain factors were generated from exp=xcsx35617:run=544

- data with water ring for comparison exp=xcsx35617:run=528

- account relative factor 46.7

- selected rect [6, 120:170, 200:250]

gain default: H / M / L = 1 / 0.33333 / 0.01

gain from charge injection:

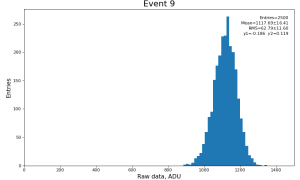

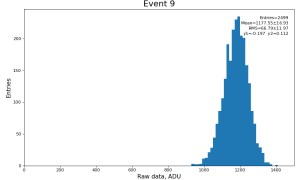

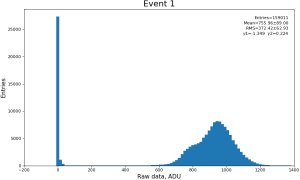

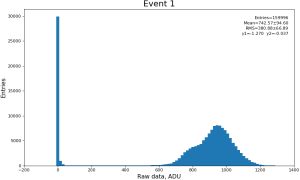

| constants | Mean | RMS | RMS / MEAN |

|---|---|---|---|

| default | 1117.7 | 62.72 | 0.05618 |

| charge injection | 1177.5 | 66.79 | 0.05672 |

Conclusion: in this test charge injection gainci constants do not improve gain factors comparing to default

Default gain correction factors

Test of the gain switching modes

offset calibration: exp=xcsx35617:run=544; its timestamp 20181129124822 faked for earlier dark calibrations by reference from 20180101000000

dark runs: 413, 416, 417, 420 of xcsx35617

gain factors M, H=1, L= 0.2, 0.25, 0.3, 0.33333, 0.4

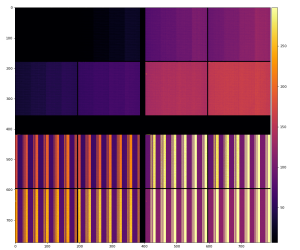

gain map images show that lateral and central-most pixels in mode H, M, "water ring" region pixels switched to L

data:

- AML: exp=xcsx35617:run=419, event 3

- AHL: exp=xcsx35617:run=414, event 3

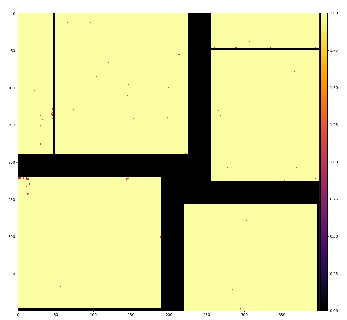

Masks

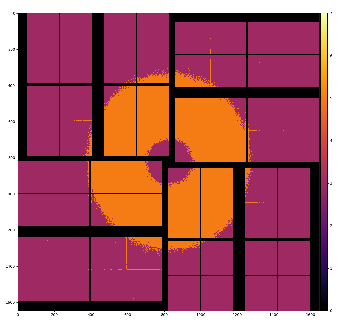

mask_geo

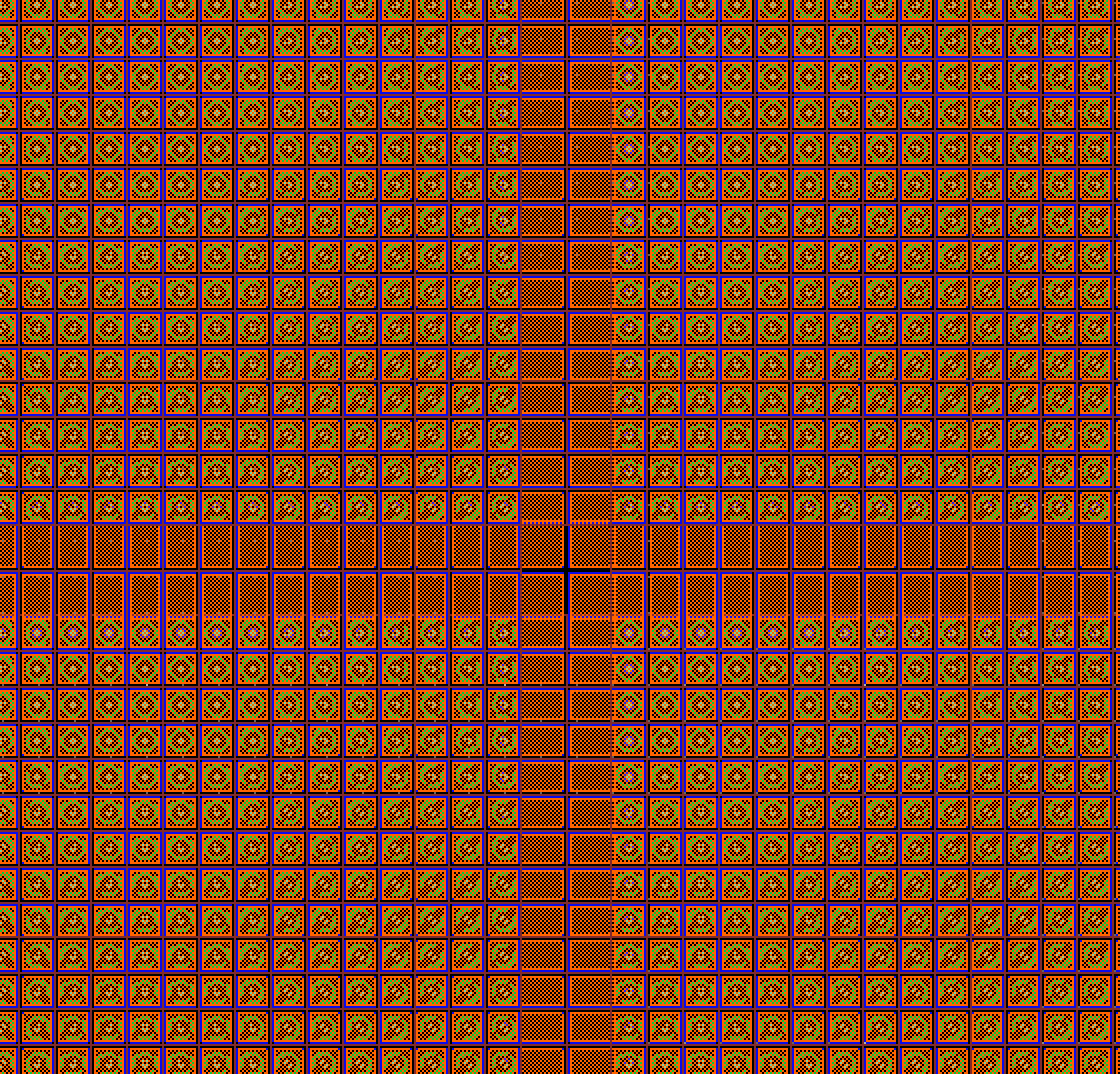

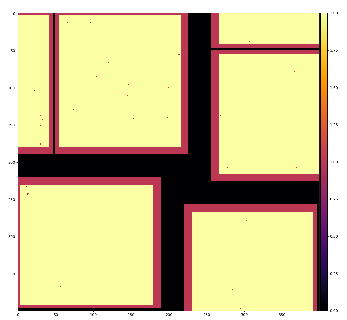

mask_geo = det.mask_geo(par, mbits=3, width=10, wcentral=5)

- mbits = 1 - masks edges, +2 - masks central rows and columns.

- width - number of edge rows or columns to mask, def=1

- wcentral - number of central rows or columns to mask, def=1

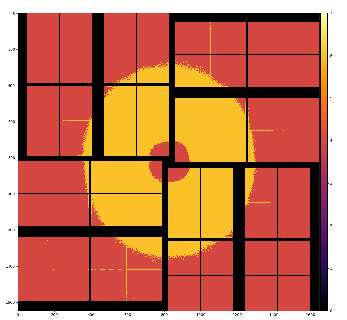

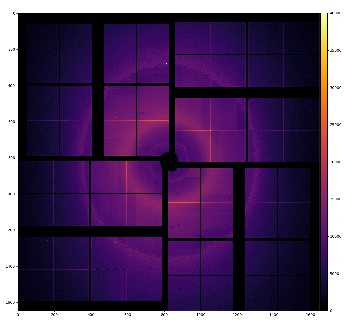

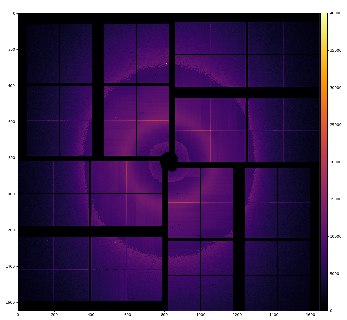

plot for mask_geo + 1:

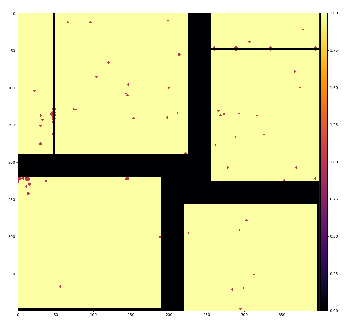

status_as_mask

- use pixel_status for exp=xcsx35617:run=544

- mask_status = det.status_as_mask(par, mode=0, indexes=(0,1,2,3,4))

- mode 0/1/2 masks zero/four/eight neighbors around each bad pixel

- indexes=(0,1,2,3,4) # indexes stand for FH, FM, FL, AHL-H, AML-M, respectively. Derived modes have the same status arrays.

found number of bad pixels

- 2802 for F gain modes and

- 3253 for all F + A mode

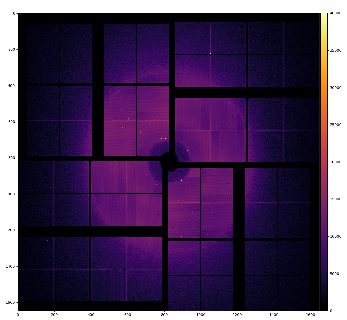

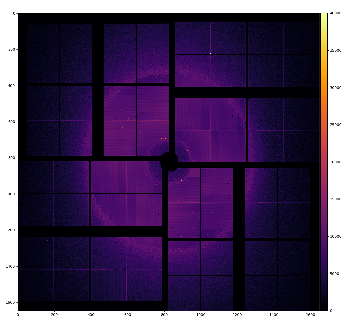

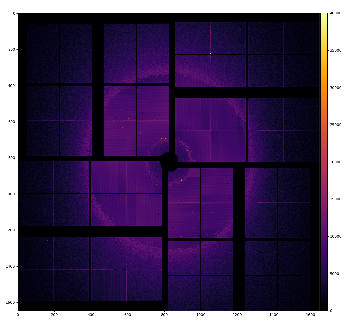

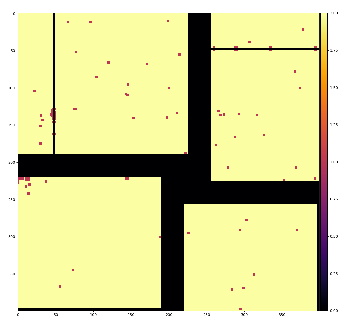

plots for mask_status + 1 for mode=0, 1 and 2:

Combined mask

mask = det.mask(par, calib=False, status=True, edges=True, central=True, width=10, wcentral=5, mode=0)

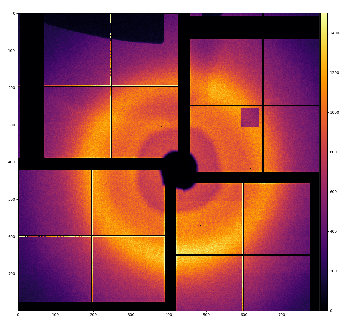

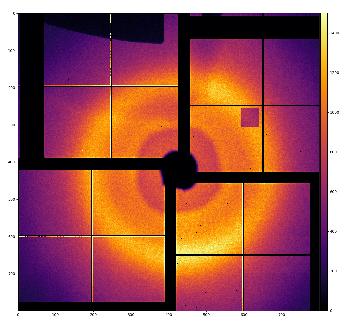

Calibrated data and mask

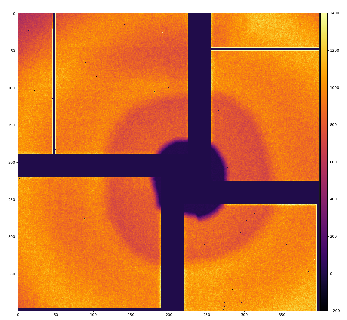

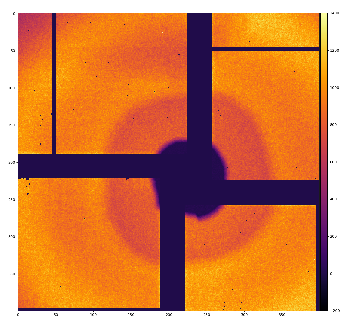

Image and spectrum for

- nda = calib_epix10ka_any(det, evt)

- nda *= det.mask(par, calib=False, status=True, edges=True, central=True, width=1, wcentral=1, mode=0)

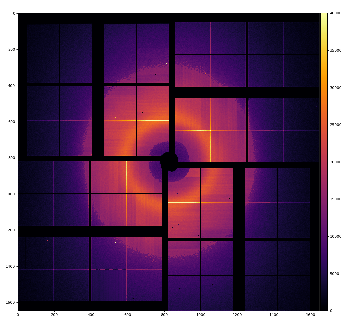

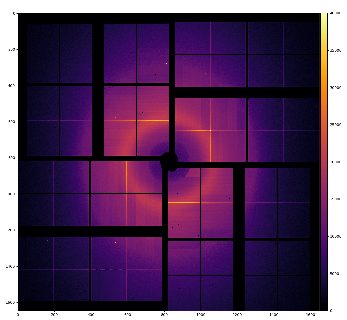

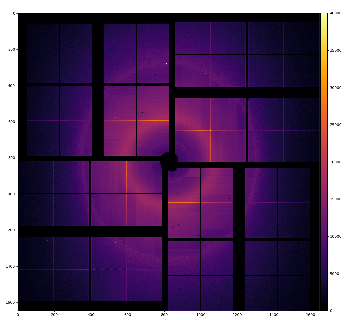

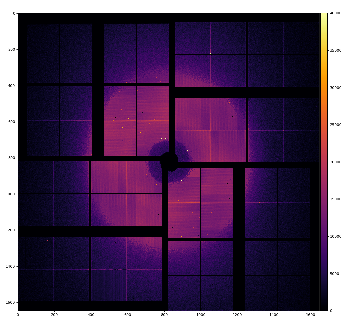

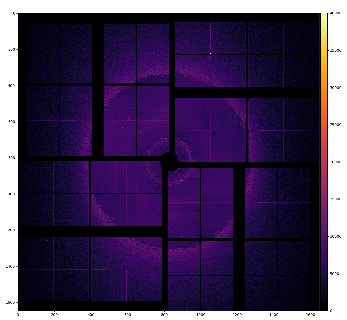

Manual alignment on 2019-05-06

Data

Ring-data (npy) arrays were provided for xcsx35617 run 400 by Silke, available under

- /reg/g/psdm/detector/alignment/epix10ka2m/calib-mfx-epix10ka2m-01-2018-11-15/2019-05-06-geometry-alignment/

Alignment tool

Manual Detector alignment tool (geo) is used for alignment. There is no automated geometry optimization in this tool.

Initial geometry

Alignment is started with the best geometry file obtained after optical metrology measurements for two quads, like

/reg/g/psdm/detector/alignment/epix10ka2m/calib/Epix10ka2M::CalibV1/NoDetector.0:Epix10ka2M.0/geometry/geo-epix10ka2m-v180

or

/reg/d/psdm/xcs/xcsx35617/calib/Epix10ka2M::CalibV1/XcsEndstation.0:Epix10ka2M.0/geometry/398-398.data

Alignment procedure

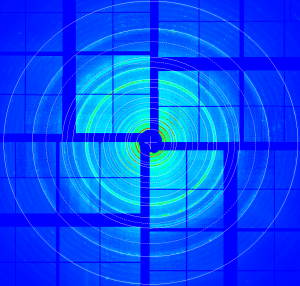

Quads' x0,y0 - center positions ONLY have been tuned as explained here:

1) Q0 and Q1 were moved together relative to the image center, because their geometry is constrained from optical metrology.

2) then Q2 and Q3 were moved independently in order to get consistent "to my eye" image relative to a set of drown circles.

Geometry for panels inside Q2 and Q3 is set from design geometry, and I do not feel that could do better job moving panels in quad.

There are some regular alignment issues with this detector; if I tune nicely (with precision ~ pixel size) rings in the middle of radial range,

then internal and external rings may be misaligned. This may be due to small tilt of the detector or non-accounted z position of panels

w/o optical metrology.

Results

Resulting geometry for this data looks like on attached image.

All files are available under

- /reg/g/psdm/detector/alignment/epix10ka2m/calib-mfx-epix10ka2m-01-2018-11-15/2019-05-06-geometry-alignment/

Recommendation for further geometry improvement

The only reliable procedure to get correct detector geometry is an 3-d optical metrology of entire detector.

After that one would need to adjust precisely

1) detector center relative to image with rings

2) sample-to-detector distance

3) detector plane tilts.

References

- EPIX10KA2M References

- EPIX10KA

- EPIX10KA2M data images and geometry

- Production of calibration constants for multi-panel epix10ka detectors

- EPIX10KA2M Charge injection fit issue

- EPIX10KA2M issue with panel 6 in mfxc00318

- EPIX10KA2M issue with panel 12 in xcsc00118 2M.0

- Optical metrology of epix10ka2m.1 from 2020-02-25

- EPIX10KA panel flatness measurement

- Jungfrau and Epix10ka Calibration

- Detector alignment tool

- 2020-08-20-new-x-ray-detector-snaps-1000-atomic-level-pictures-second-natures-ultrafast