Two new detectors EPIX10KA2M and EPIX10KAQUAD are composed from EPIX10KA modules.

Content

Geometry

Kenney, Christopher J. 2018-11-12, 2:26 PM

Guide tube is 7mm outer diameter

We added polyimide tape that was 150 microns thick before application

to the tube.

But a decent estimate would be the mechanical edge-to-edge orthogonal

separation between sensor edges 7.3 mm.

We need to add about 1 mm for the guard rings on each sensor

So the orthogonal gap between active pixels on opposing quads across

the beam guide tube should be 8.3 mm

====

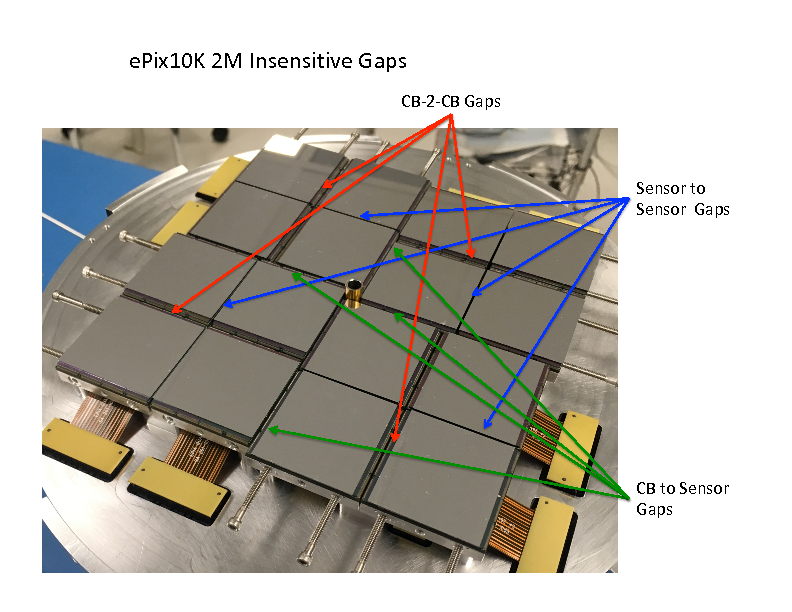

Kenney, Christopher J. 2018-11-12, 4:41 PM Blaj, Gabriel;Dubrovin, Mikhail;Kwiatkowski, Maciej

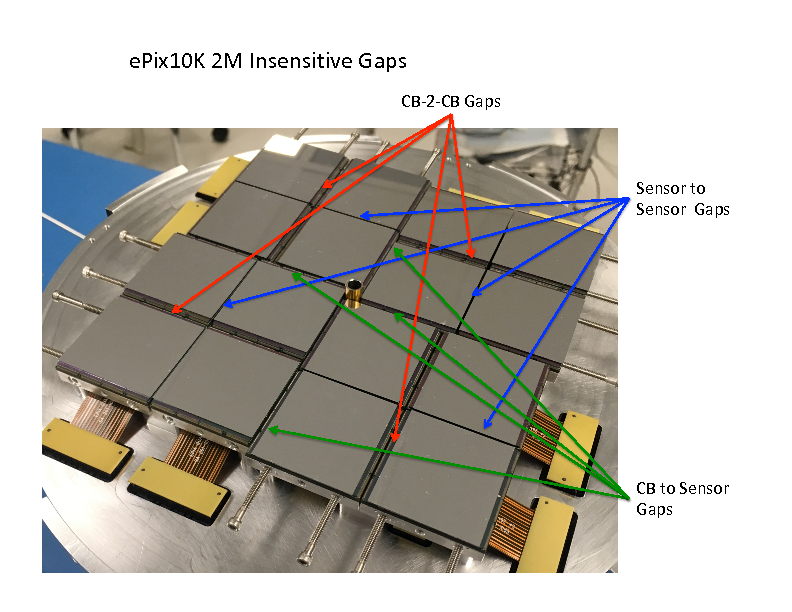

Very rough estimate of the gaps

There are 3 types of gaps

All are active pixel to active pixel

sensor to sensor ~ 1.6 mm

CB to CB ~ 6.4 mm

sensor to CB ~ 3.9 mm

====

CB = Carrier Board edges

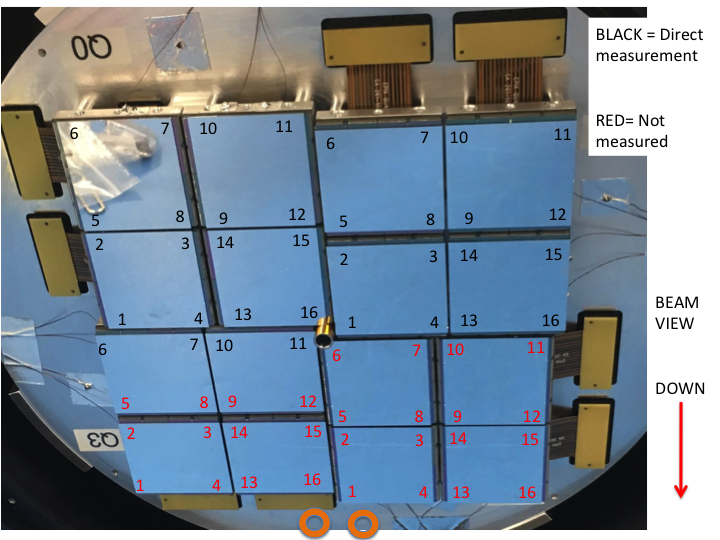

Full camera image below

====

so 384 columns parallel to the balcony (the widest dead gaps)

and 352 orthogonal to the balcony (vertical direction)

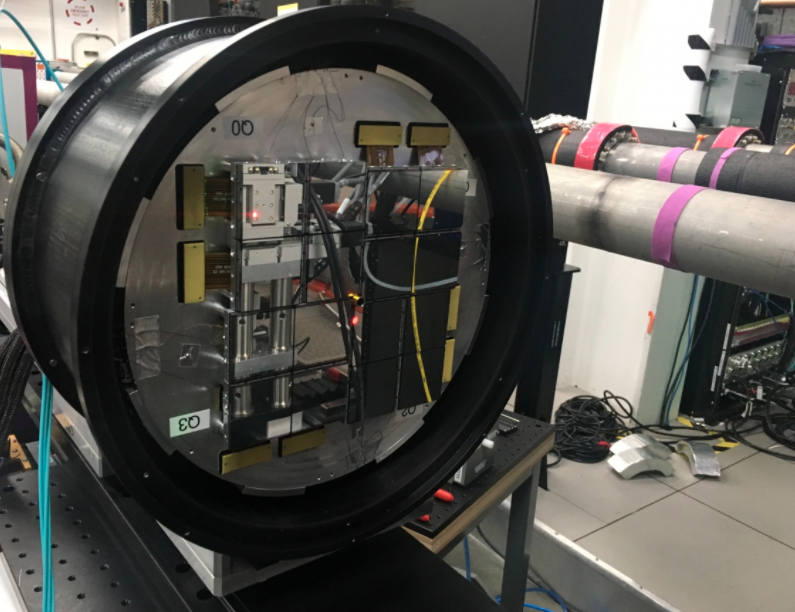

epix10ka2m assembly

epix10ka2m-insensitive-gaps.pdf

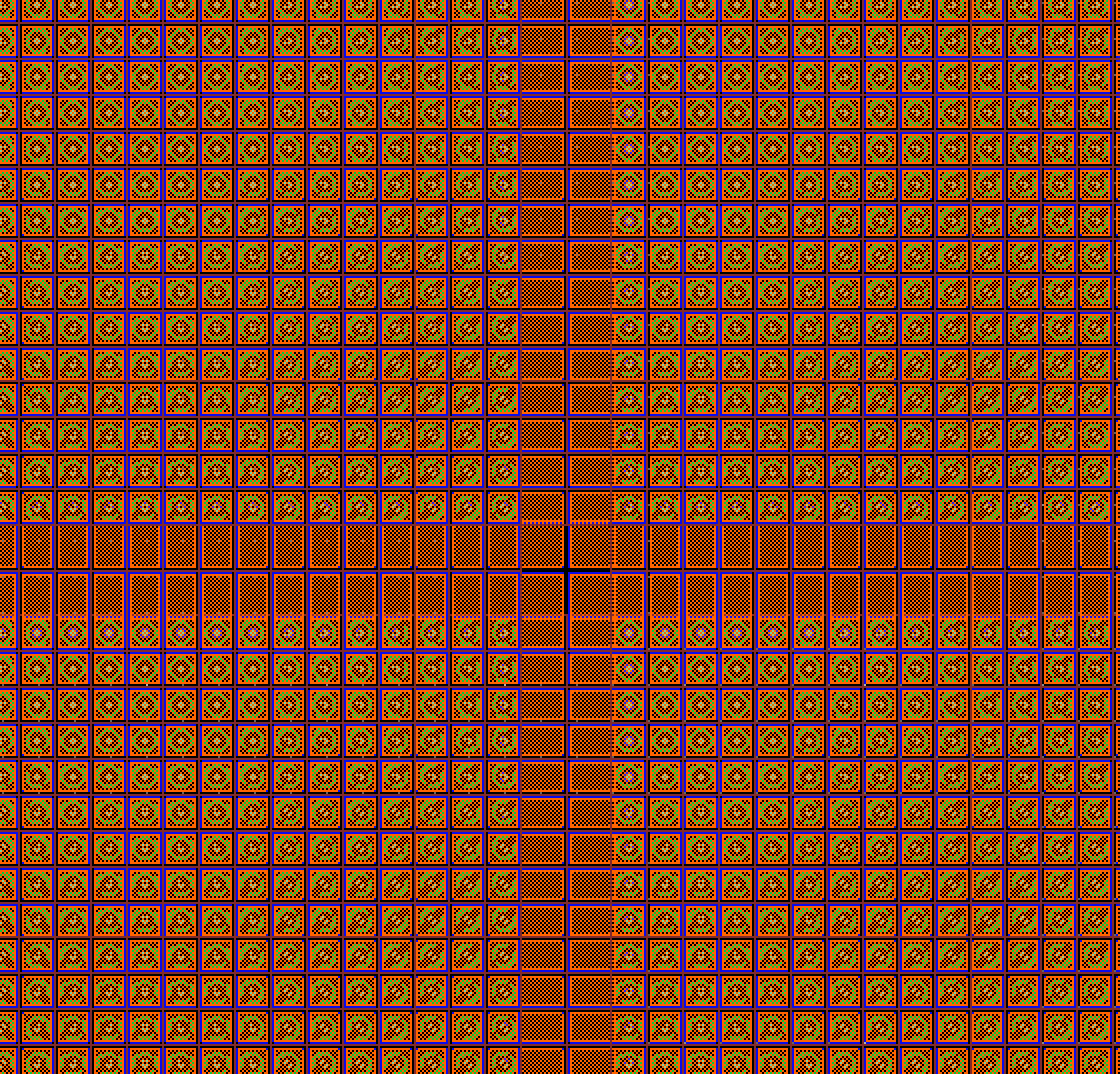

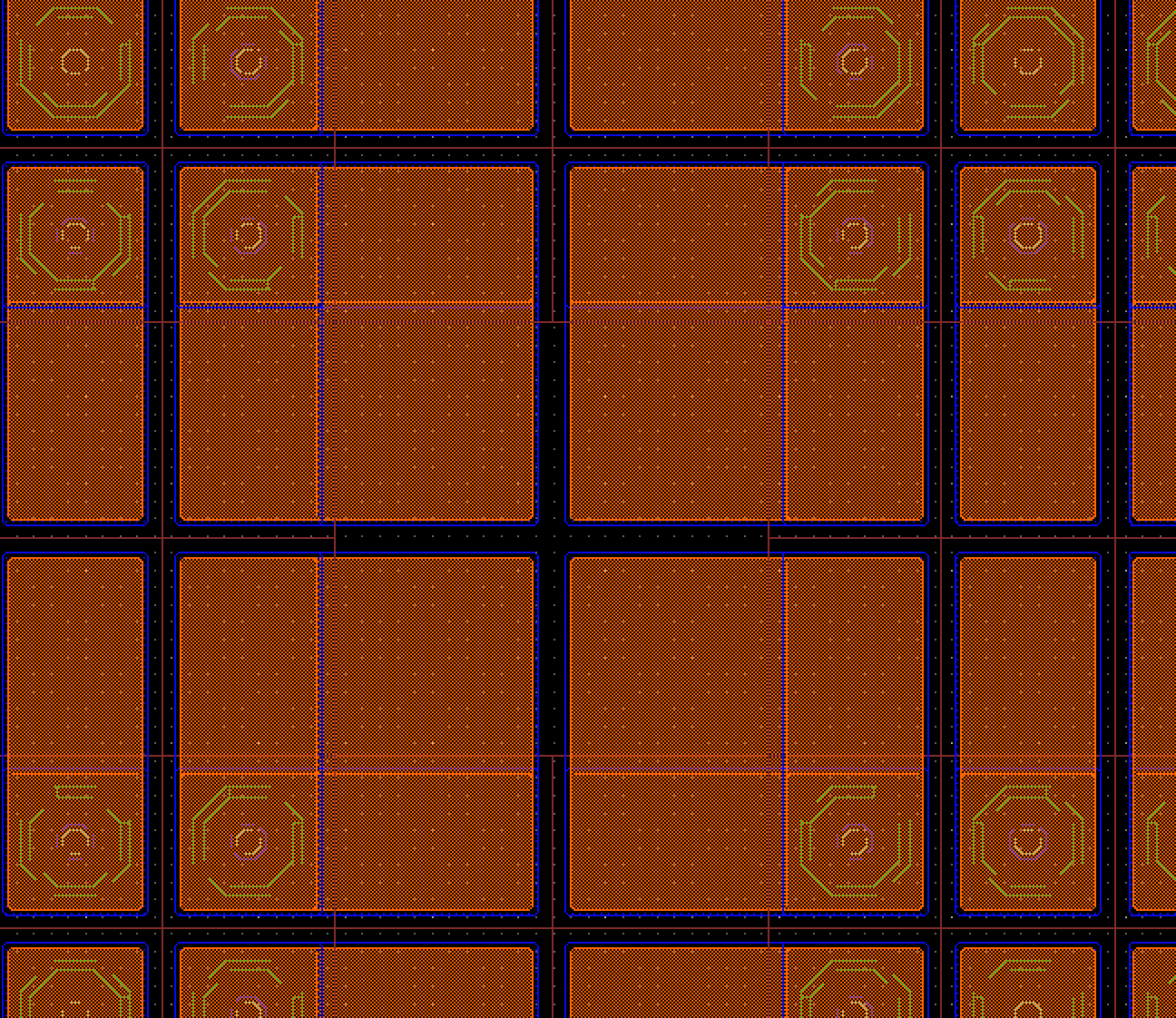

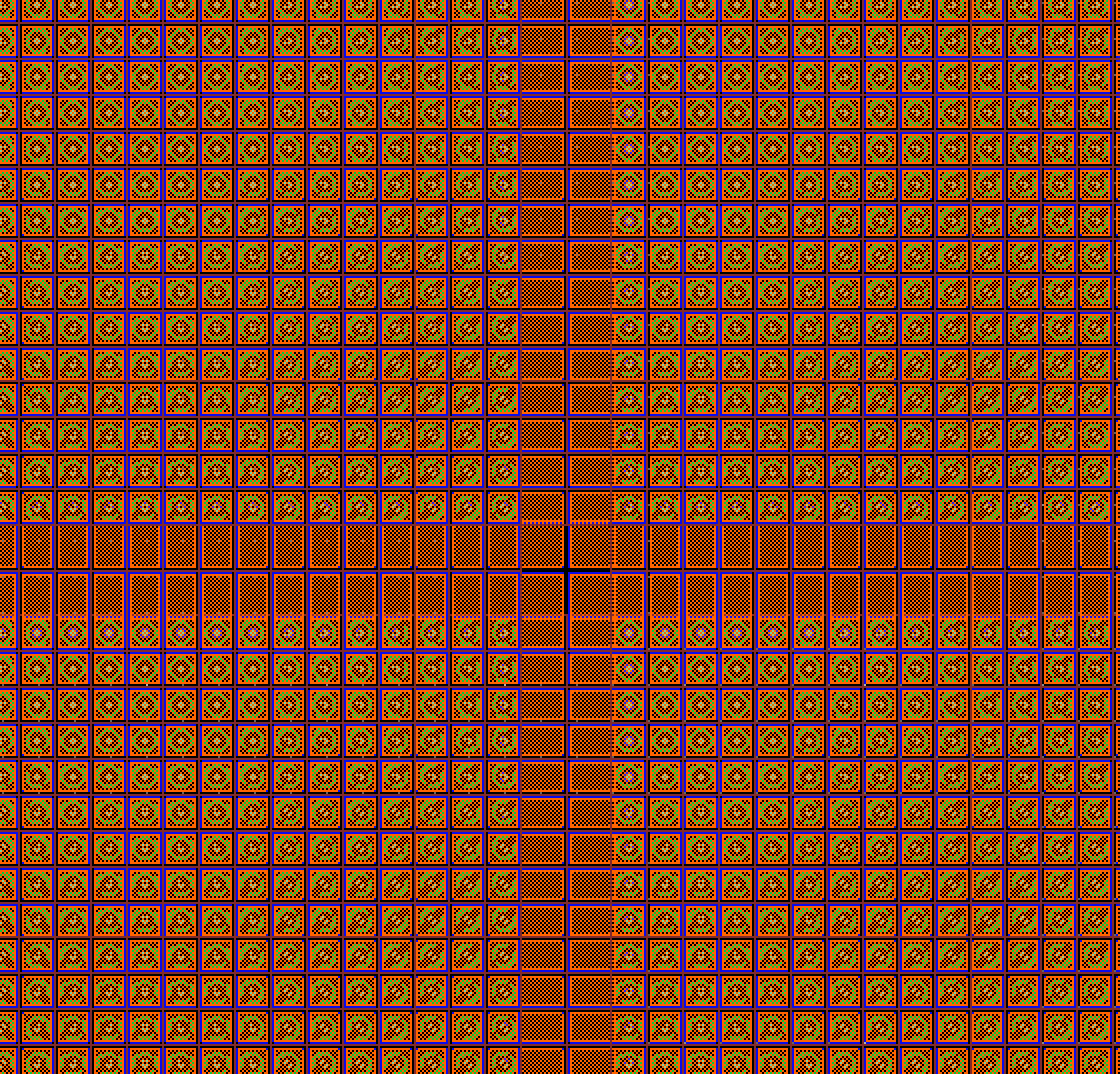

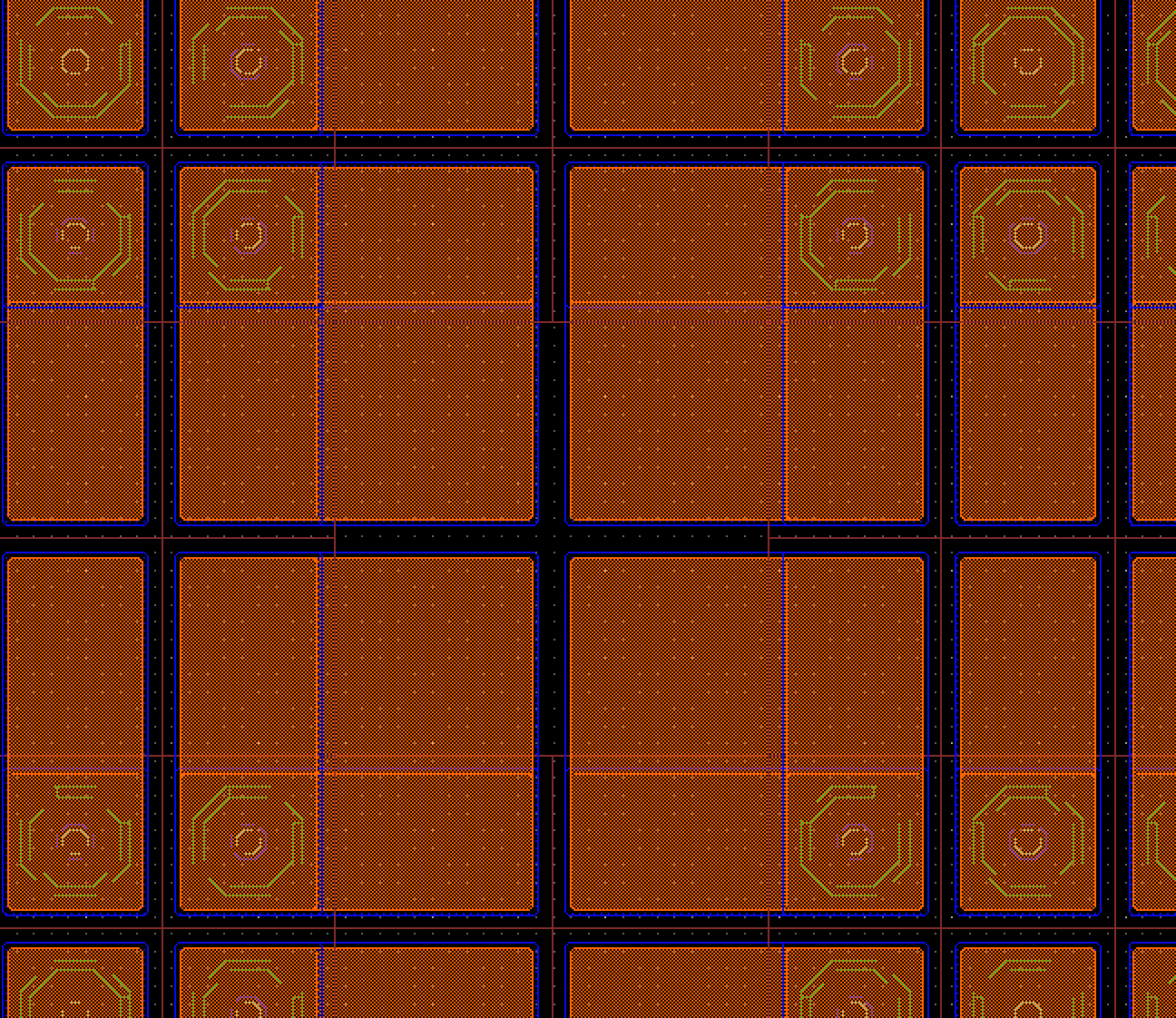

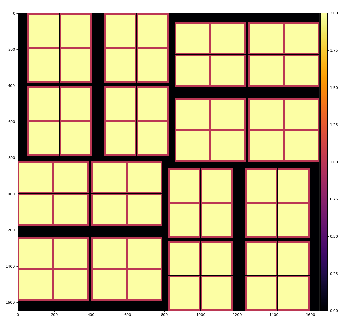

epix10ka sensor central region between 4 ASICs

The internal gap between four ASICs in sensor,

pixel size 100 x 225 microns in area in both directions.

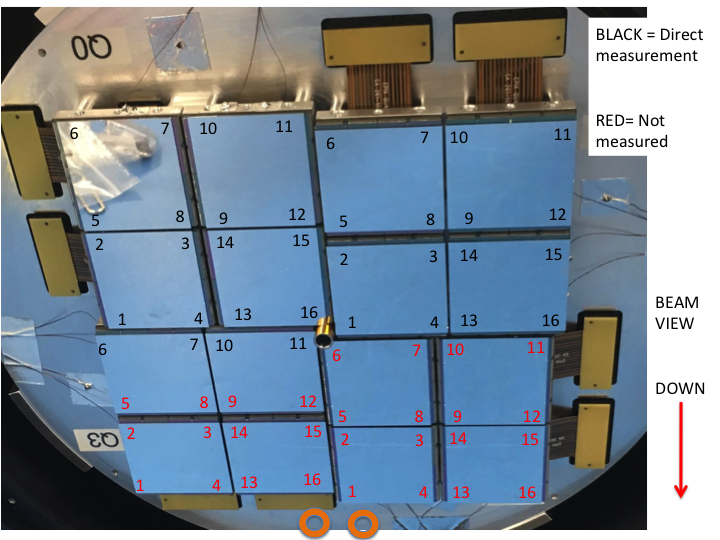

Metrology map from Chris Kenney

Back side of the new detector epix10ka2m.1 from mfxc00118 2020-07-dd

Weaver, Matt

2018-11-19, 7:37 PMO'Grady, Paul Christopher;Dubrovin, Mikhail

Hi Mikhail,

We took radioactive source test

runs today to verify the geometry. We found that we were rotated by 90

degrees, which matches the labeling on the back of the detector as well

as the metrology picture from Chris Kenney.

The runs are

/reg/d/psdm/det/detdaq17/e968-r0131 - source unmasked (up to ~ event 10000), then masked vertically after ~ event 15000

/reg/d/psdm/det/detdaq17/e968-r0132 - source masked horizontally at bottom after ~ event 15000.

So, the picture is...

// (Epix10ka2m)

// |

// Quad 0 | Quad 1 Quad 2 is rotated 90d clockwise

// -------+-------- Quad 3 is rotated 180d clockwise

// Quad 3 | Quad 2 Quad 0 is rotated 270d clockwise

// |

//

// (Quad 1)

// |

// Elem 0 | Elem 1

// -------+-------- No rotations

// Elem 2 | Elem 3

// |

//

// (Elem 0)

// |

// ASIC 0 | ASIC 3

// -------+-------- No rotations

// ASIC 1 | ASIC 2

// |

//

// (Elem 0-3 pixel array)

// row increasing

// ^

// |

// |

// column increasing <-- (0,0)

Preliminary geometry

in /reg/g/psdm/detector/data_test/calib/

/reg/g/psdm/detector/data_test/calib/Epix10ka2M::CalibV1/NoDetector.0:Epix10ka2M.0/geometry/0-end.data @ (epix10ka2m - entire detector)

/reg/g/psdm/detector/data_test/calib/Epix10kaQuad::CalibV1/NoDetector.0:Epix10kaQuad.0/geometry/0-end.data @ (epix10kaquad - one quad)

/reg/g/psdm/detector/data_test/calib/Epix10ka::CalibV1/MecTargetChamber.0:Epix10ka.1/geometry/0-end.data @ (epix10ka - one panel)

copy of geometry files in alignment examples /reg/g/psdm/detector/alignment/

/reg/g/psdm/detector/alignment/epix10ka2m/calib/Epix10ka2M::CalibV1/NoDetector.0:Epix10ka2M.0/geometry/0-end.data

/reg/g/psdm/detector/alignment/epix10kaquad/calib/Epix10kaQuad::CalibV1/NoDetector.0:Epix10kaQuad.0/geometry/0-end.data

/reg/g/psdm/detector/alignment/epix10ka/calib/Epix10ka::CalibV1/MecTargetChamber.0:Epix10ka.1/geometry/0-end.data

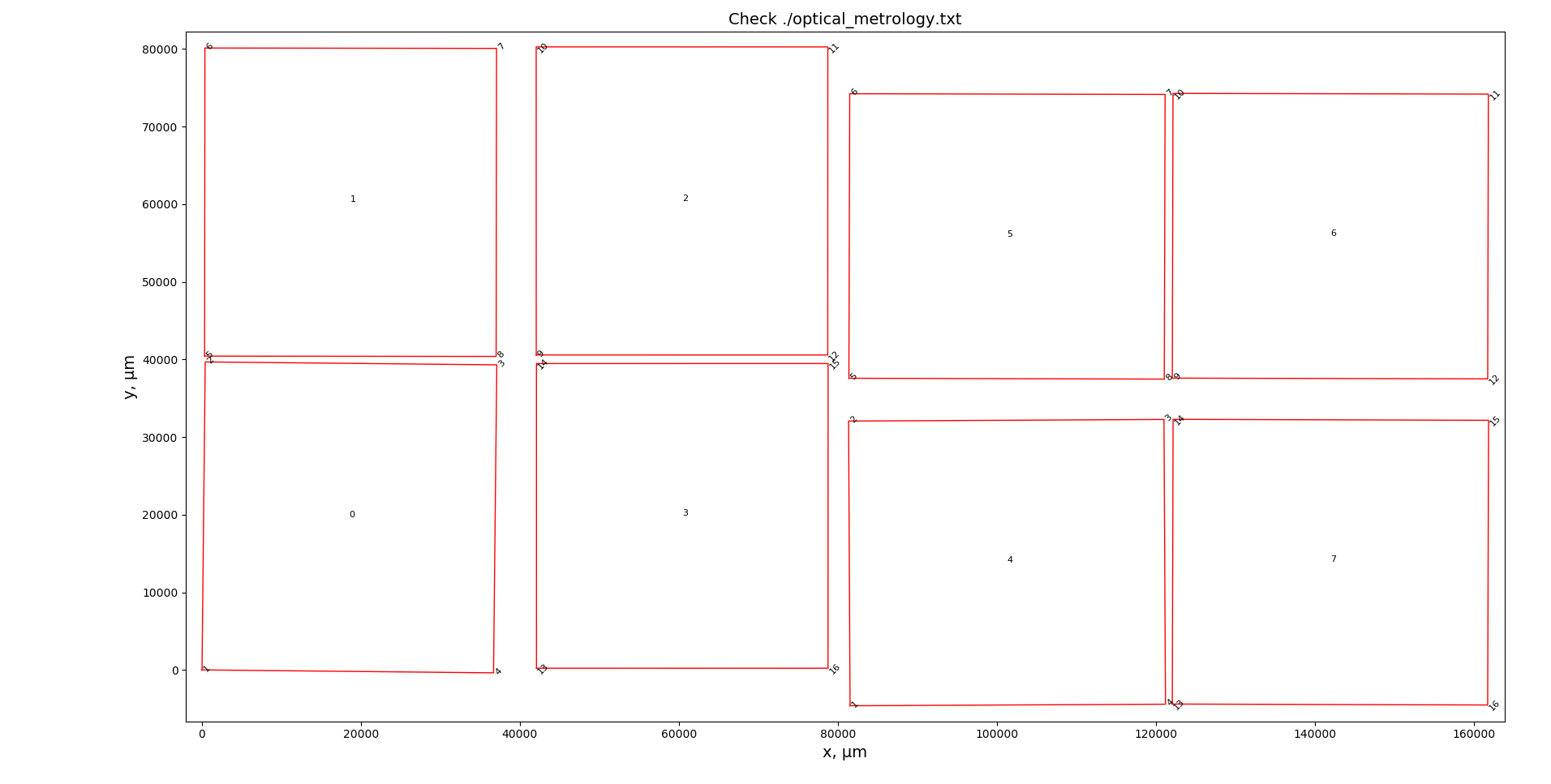

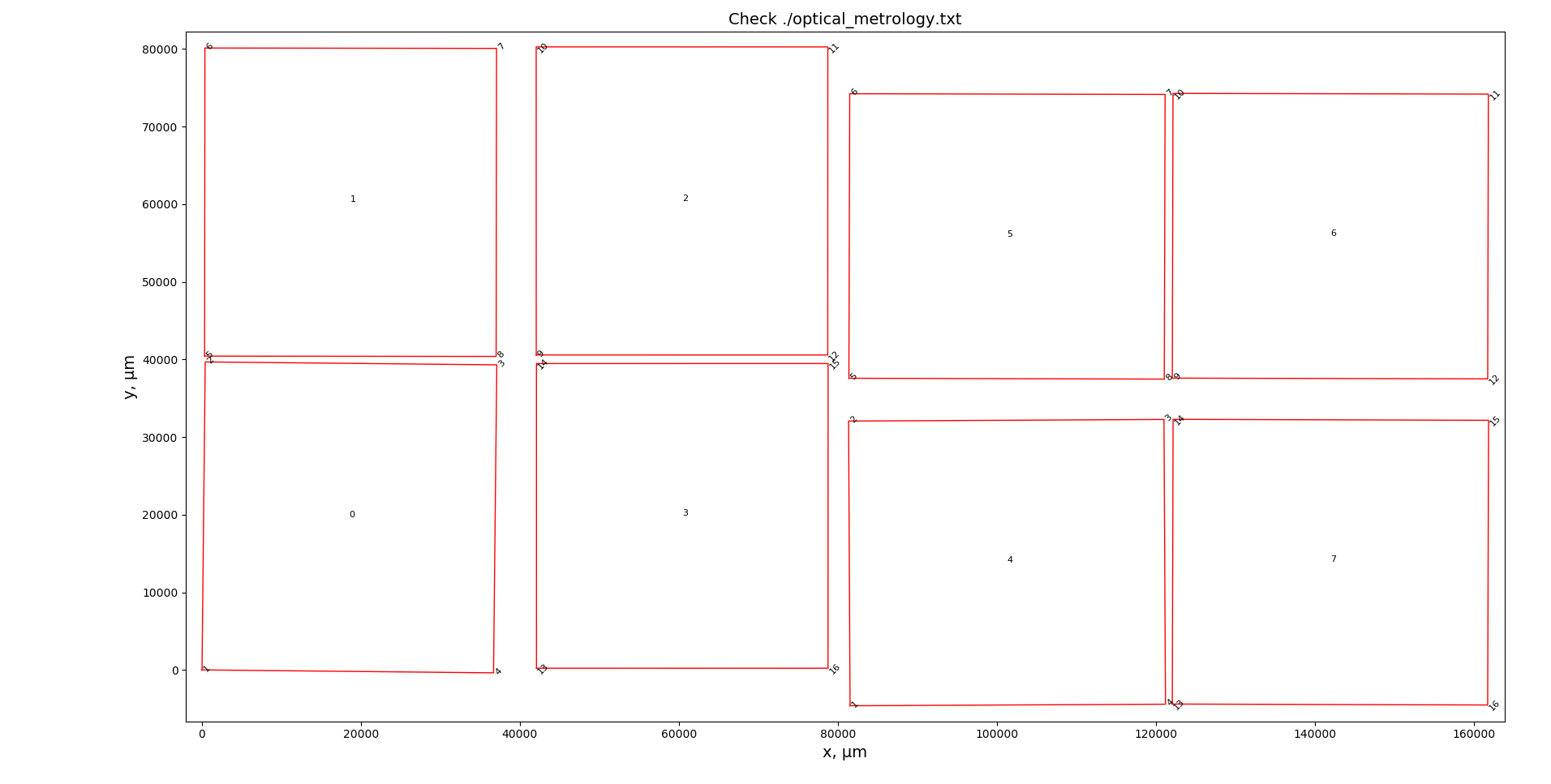

Optical metrology processing

Scripts for processing

CalibManager/app/

optical_metrology_check

optical_metrology_epix10ka2m

Results in

/reg/g/psdm/detector/alignment/epix10ka2m/calib-mfx-epix10ka2m-01-2018-11-15/

2018-11-15-Metrology-epix10ka2m.xlsx

2018-11-15-Metrology-epix10ka2m.txt

2018-11-15-Metrology-epix10ka2m-corr.txt

2018-11-15-geometry-epix10ka2m.txt - geometry file accounting for optical metrology data

README-2018-11-15

Gain

Blaj, Gabriel

2018-12-04, 2:08 PMO'Grady, Paul Christopher;Nelson, Silke;Dubrovin, Mikhail;Hart, Philip Adam

Hi,

You could try to use the gain files obtained with the pulser. They are not great but might work.

For a better gain calibration, we should use single photon data.

There is sufficient 1 photon data taken during the first testing at XCS,

but it will take me a few days to calculate the gains.

I would actually advocate returning the number of photons (as we

discussed in a meeting a few months ago). Even without a calibration it

can be easily calculated from the (average) gains:

High (FH and AHL): 132 ADU/9.5 keV

Medium (FM and AML): 43 ADU/9.5 keV

Low (FL, AHL, AML): 1.32 ADU/9.5 keV

(Just a note, while the pulser is not great for calibrating gains, it works fine for offset calibration)

Thanks,

Gabriel

Gain factors from charge injection default and measured

| gain | charge injection | current default | measured (ADU / keV) | 2020-08-03 Gabriel (ADU / keV) - use as default |

|---|

| L | 0.46 | 0.01 | 0.139 | 0.164 |

| M | 15. | 0.3(3) | 4.5 | 5.466 |

| H | 46.7 | 1 | 13.9 | 16.40 |

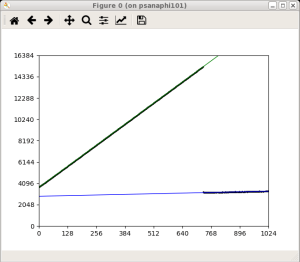

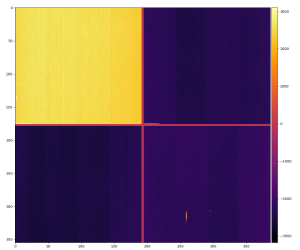

Gain factors default vs charge injection

- Detector/examples/ex_epix10ka_images.py

- XcsEndstation.0:Epix10ka2M.0

- charge injection gain factors were generated from exp=xcsx35617:run=544

- data with water ring for comparison exp=xcsx35617:run=528

- account relative factor 46.7

- selected rect [6, 120:170, 200:250]

gain default: H / M / L = 1 / 0.33333 / 0.01

gain from charge injection:

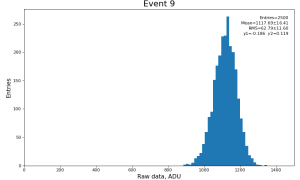

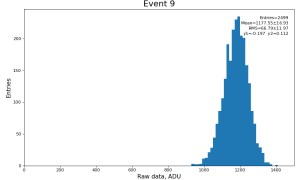

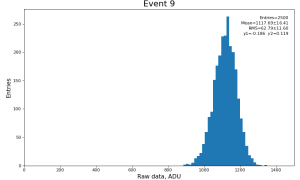

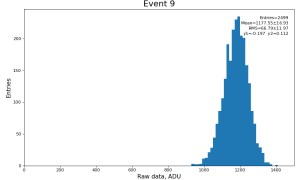

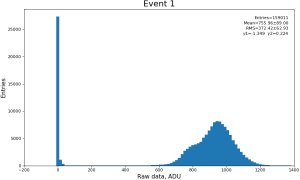

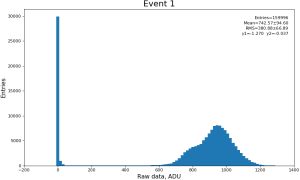

| constants | Mean | RMS | RMS / MEAN |

|---|

| default | 1117.7 | 62.72 | 0.05618 |

| charge injection | 1177.5 | 66.79 | 0.05672 |

Conclusion: in this test charge injection gainci constants do not improve gain factors comparing to default

Default gain correction factors

Blaj, Gabriel <blaj@slac.stanford.edu> Mon 8/3/2020 6:52 PM

To: Hart, Philip Adam;

Dragone, Angelo;

Kenney, Christopher J.;

Dubrovin, Mikhail;

O'Grady, Paul Christopher;

Hansson, Conny;

McKelvey, Mark E

Hi, Here are some good starting values for the ADC to keV conversion:

High gain: 132 ADU / 8.05 keV = 16.40 ADU/keV

Medium gain: 132 ADU / 8.05 keV / 3 = 5.466 ADU/keV

Low gain: 132 ADU / 8.05 keV / 100 = 0.164 ADU/keV

Of course, a gain calibration is preferable.

The same numbers work in both fixed and auto-ranging gain modes.

Thanks,

Gabriel

=========

Blaj, Gabriel <blaj@slac.stanford.edu> Mon 8/3/2020 7:13 PM

Hi, For the long integration time, I don't have a set of magic numbers, but this iterative procedure should yield optimal settings:

Cool the camera as low as possible, just a few degrees over the minimum temperature to allow temperature stabilization by the PID control loop (either the chiller PID for the large cameras, or the Peltier PID in the small cameras). Of course, the small cameras can be cooled much lower than the large ones.

Start with the default LCLS settings (I believe both AsicAcqWidth and R0toAcq are set to 100us by default)

0 AsicAcqWidth should be optimized for the experiment. With a very cold camera (e.g., < -15ºC) you could go to 5ms. A good starting value would be 1ms.

1 Set AsicAcqWidth to, e.g., 1 ms

2 Set R0toACQ time to 100us

3 Decrease frame rate until no frames are dropped

4 Set the X-ray source to a low flux (0.01-0.05 photons/pixel/frame?)

5 Try to get a uniform illumination

6 Repeat:

- Calibrate dark

- Take many frames and integrate them

- Look if the resulting image is uniform or has a strange sawtooth pattern over each ASIC

- If no, try reducing R0toACQ

- If yes, try increasing R0toAACQ

- Increase/decrease frame rate to the maximum frame rate that runs reliably (no dropped frames).

6 Until an optimum is found.

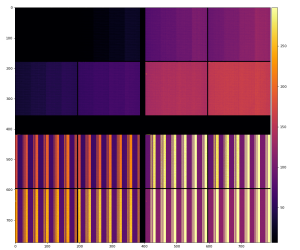

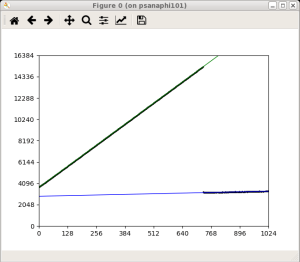

For an idea how the strange sawtooth pattern looks, you could try setting:

AsicAcqWidth = 1ms

R0toAcq = 50us, or 20us.

Thanks,

Gabriel

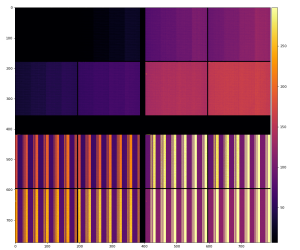

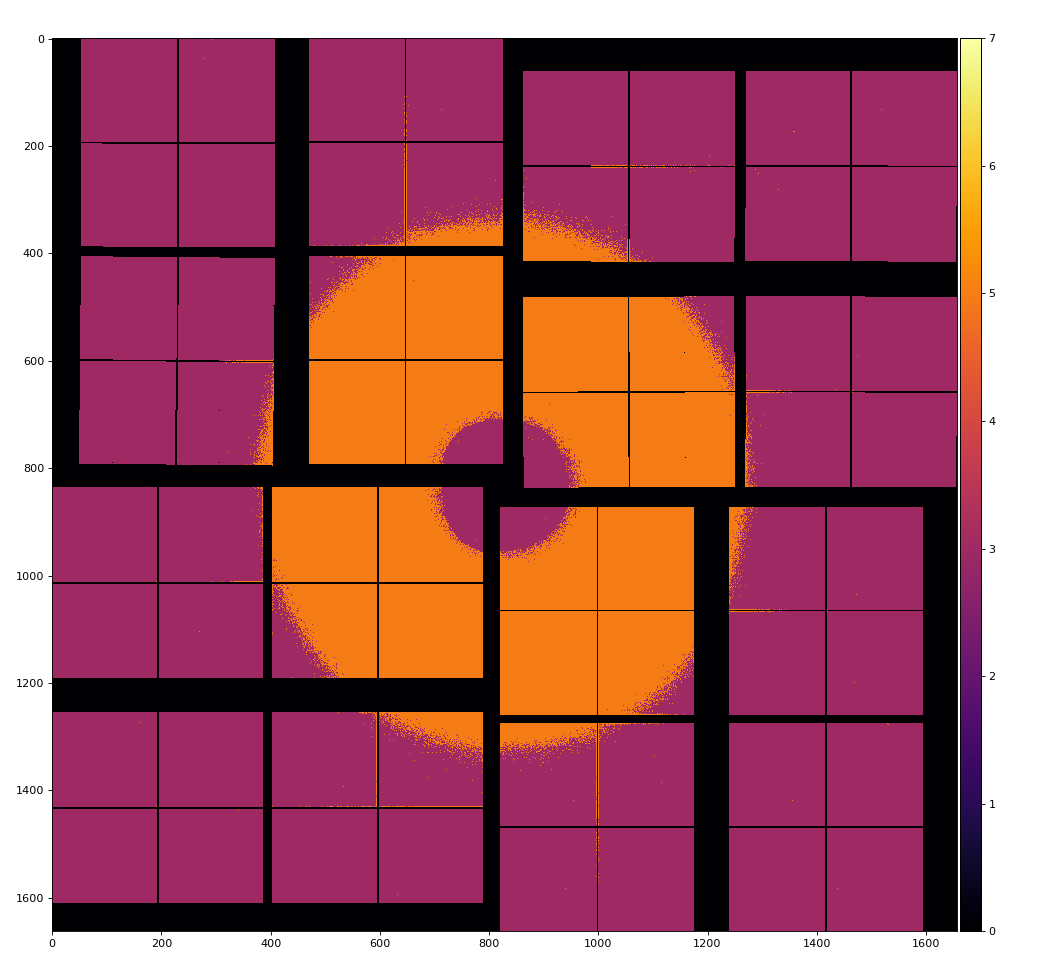

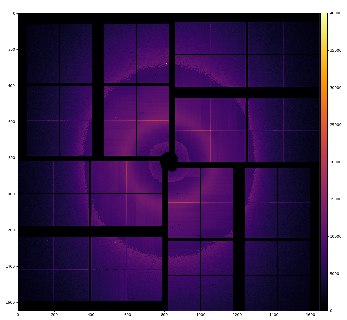

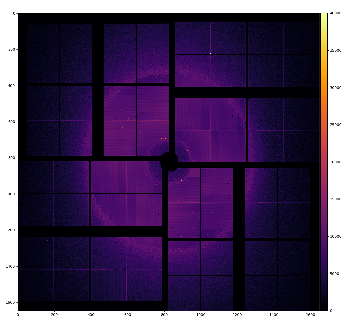

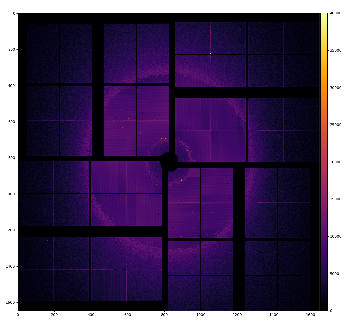

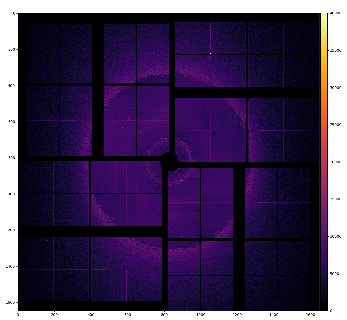

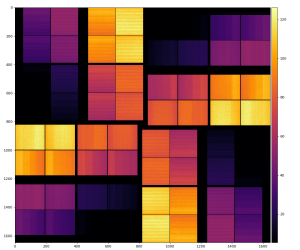

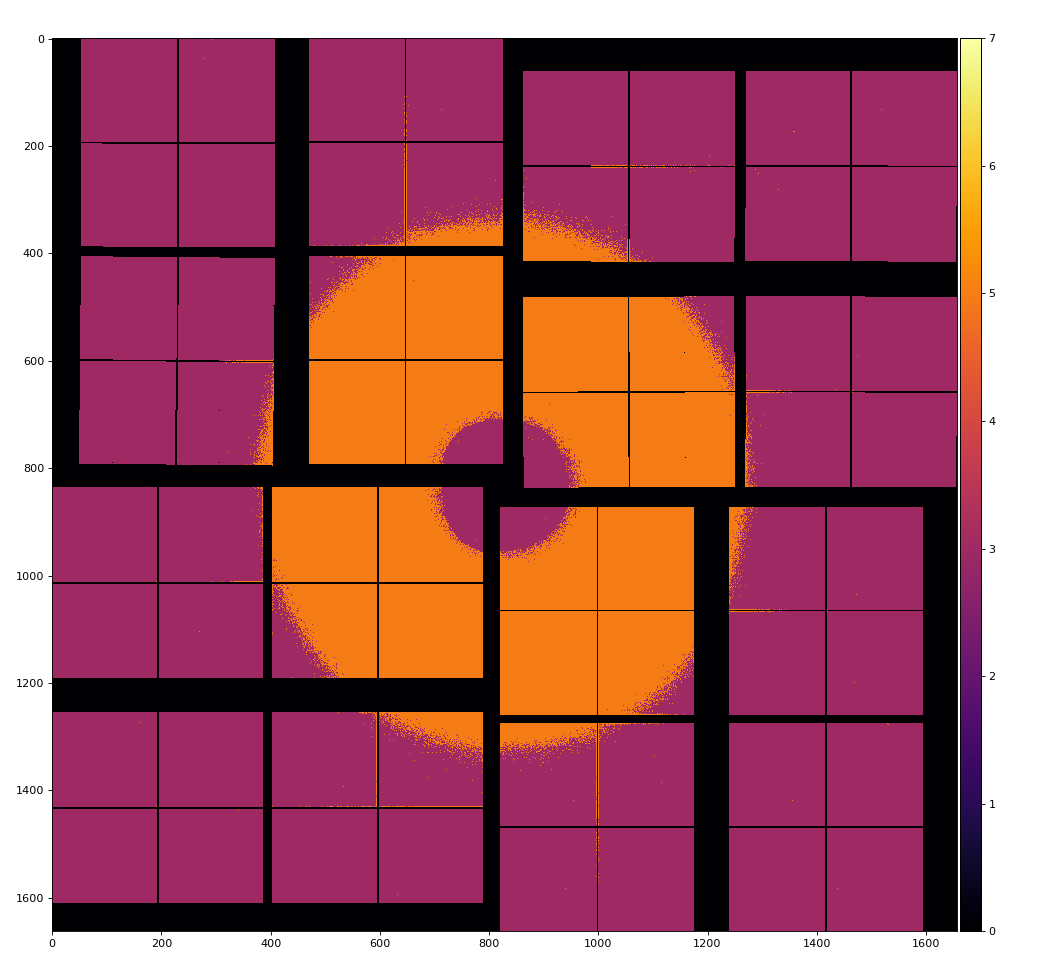

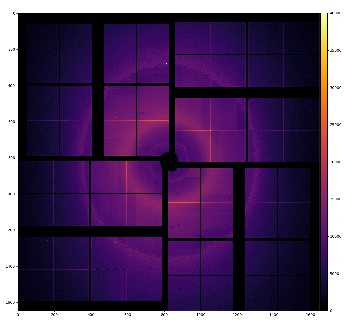

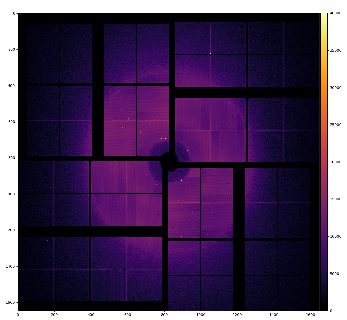

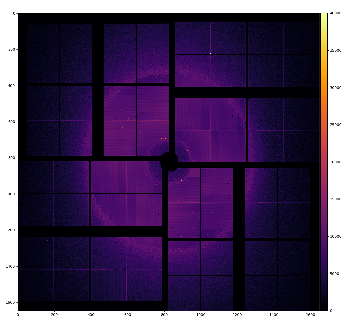

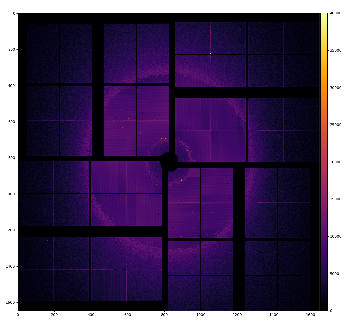

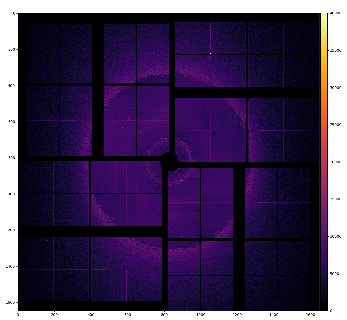

Test of the gain switching modes

offset calibration: exp=xcsx35617:run=544; its timestamp 20181129124822 faked for earlier dark calibrations by reference from 20180101000000

dark runs: 413, 416, 417, 420 of xcsx35617

gain factors M, H=1, L= 0.2, 0.25, 0.3, 0.33333, 0.4

gain map images show that lateral and central-most pixels in mode H, M, "water ring" region pixels switched to L

data:

- AML: exp=xcsx35617:run=419, event 3

- AHL: exp=xcsx35617:run=414, event 3

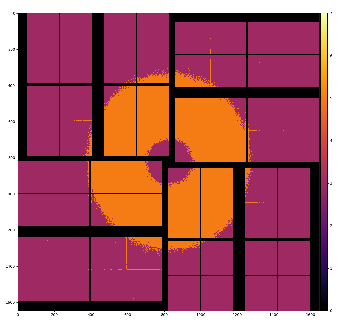

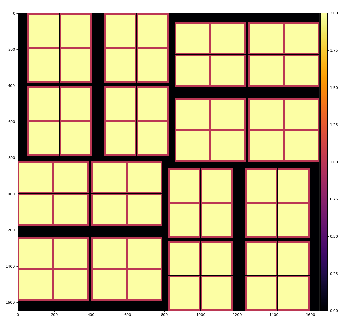

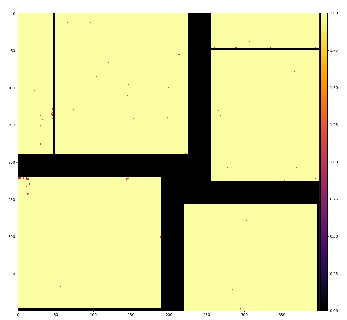

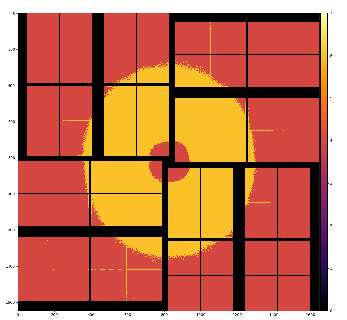

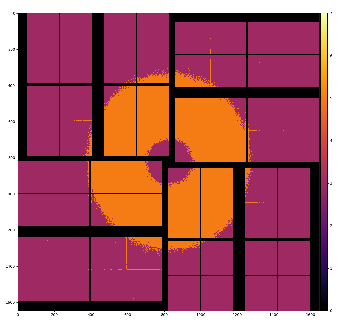

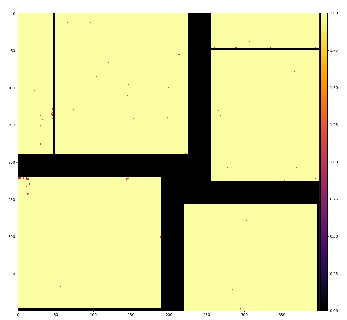

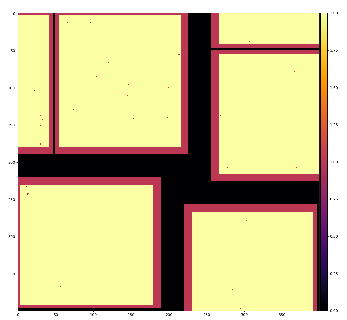

Masks

mask_geo

mask_geo = det.mask_geo(par, mbits=3, width=10, wcentral=5)

- mbits = 1 - masks edges, +2 - masks central rows and columns.

- width - number of edge rows or columns to mask, def=1

- wcentral - number of central rows or columns to mask, def=1

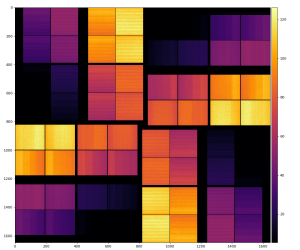

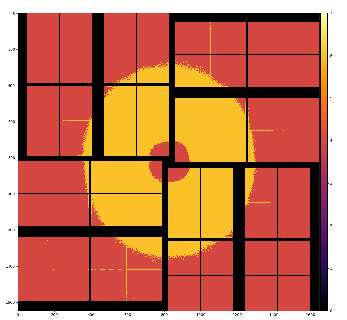

plot for mask_geo + 1:

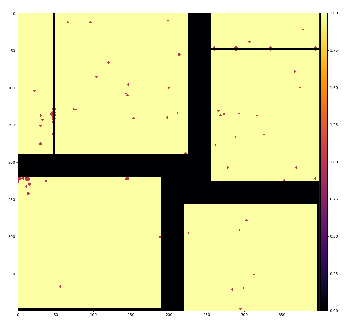

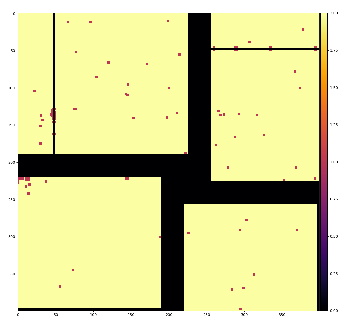

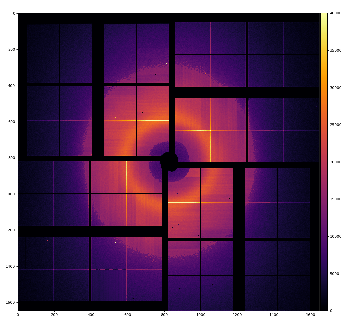

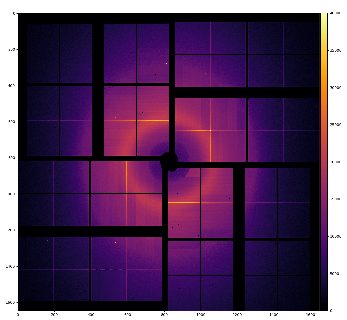

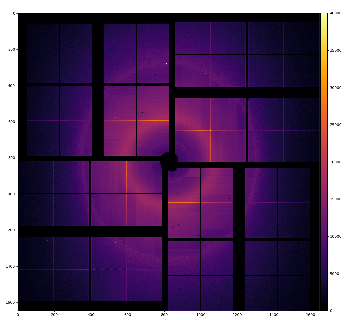

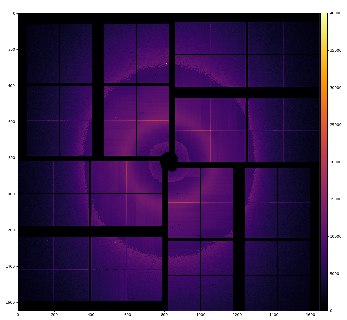

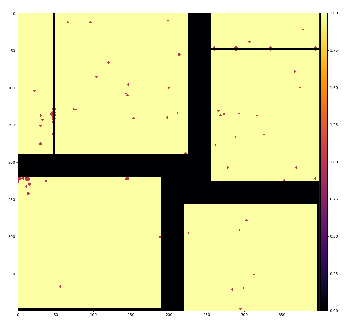

status_as_mask

- use pixel_status for exp=xcsx35617:run=544

- mask_status = det.status_as_mask(par, mode=0, indexes=(0,1,2,3,4))

- mode 0/1/2 masks zero/four/eight neighbors around each bad pixel

- indexes=(0,1,2,3,4) # indexes stand for FH, FM, FL, AHL-H, AML-M, respectively. Derived modes have the same status arrays.

found number of bad pixels

- 2802 for F gain modes and

- 3253 for all F + A mode

plots for mask_status + 1 for mode=0, 1 and 2:

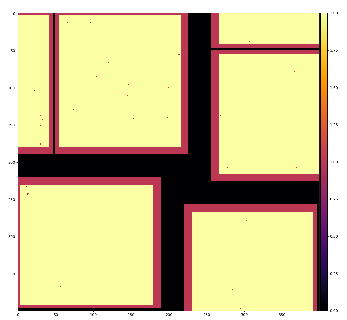

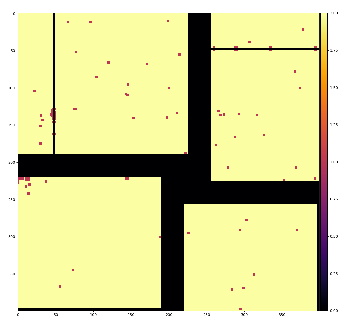

Combined mask

mask = det.mask(par, calib=False, status=True, edges=True, central=True, width=10, wcentral=5, mode=0)

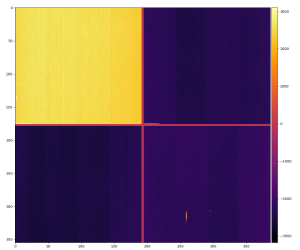

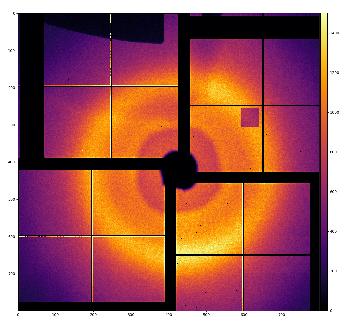

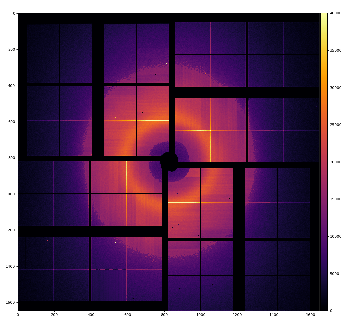

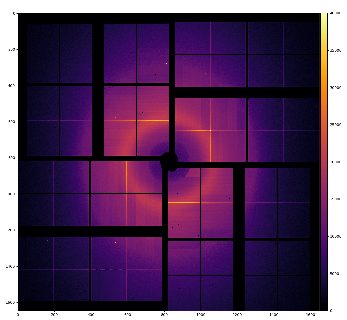

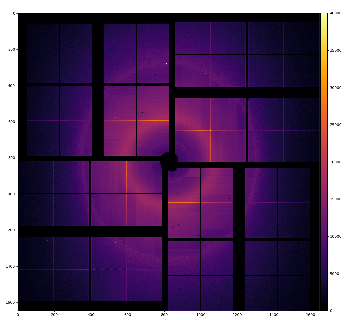

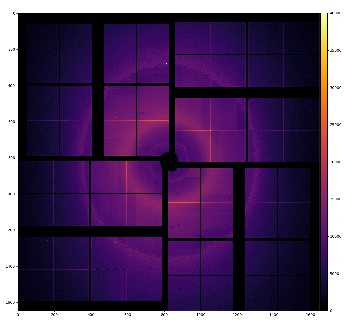

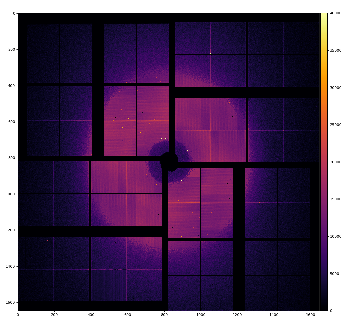

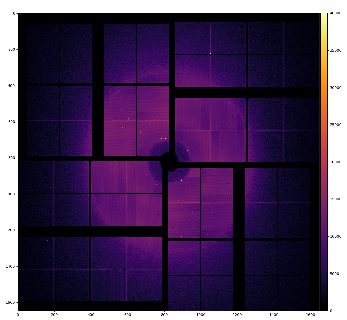

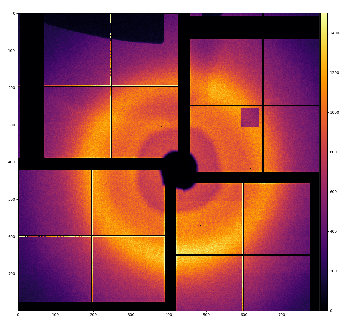

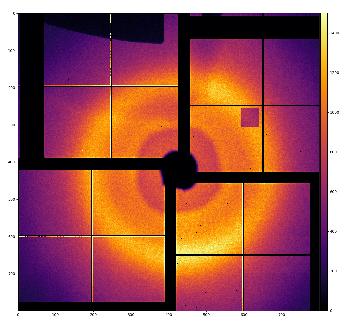

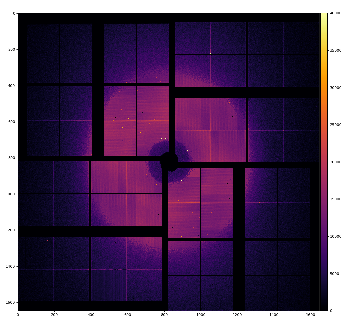

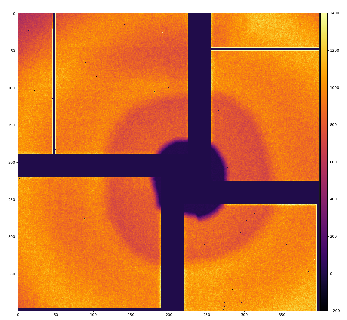

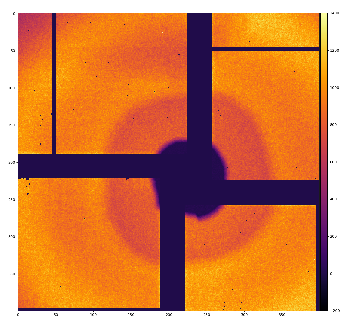

Calibrated data and mask

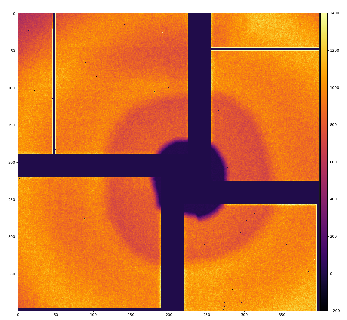

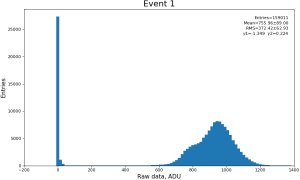

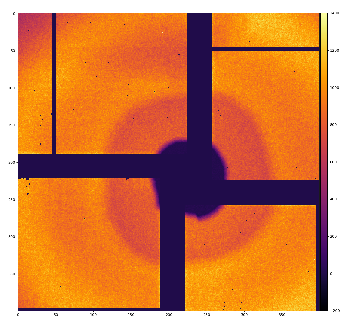

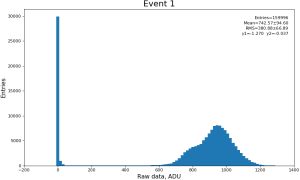

Image and spectrum for

- nda = calib_epix10ka_any(det, evt)

- nda *= det.mask(par, calib=False, status=True, edges=True, central=True, width=1, wcentral=1, mode=0)

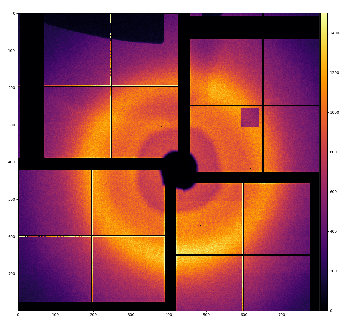

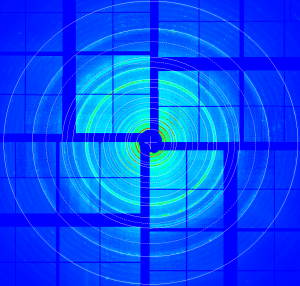

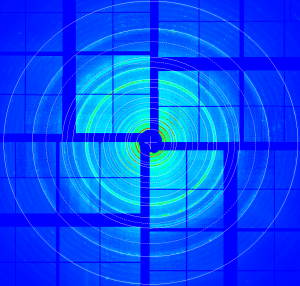

Manual alignment on 2019-05-06

Data

Ring-data (npy) arrays were provided for xcsx35617 run 400 by Silke, available under

- /reg/g/psdm/detector/alignment/epix10ka2m/calib-mfx-epix10ka2m-01-2018-11-15/2019-05-06-geometry-alignment/

Manual Detector alignment tool (geo) is used for alignment. There is no automated geometry optimization in this tool.

Initial geometry

Alignment is started with the best geometry file obtained after optical metrology measurements for two quads, like

/reg/g/psdm/detector/alignment/epix10ka2m/calib/Epix10ka2M::CalibV1/NoDetector.0:Epix10ka2M.0/geometry/geo-epix10ka2m-v180

or

/reg/d/psdm/xcs/xcsx35617/calib/Epix10ka2M::CalibV1/XcsEndstation.0:Epix10ka2M.0/geometry/398-398.data

Alignment procedure

Quads' x0,y0 - center positions ONLY have been tuned as explained here:

1) Q0 and Q1 were moved together relative to the image center, because their geometry is constrained from optical metrology.

2) then Q2 and Q3 were moved independently in order to get consistent "to my eye" image relative to a set of drown circles.

Geometry for panels inside Q2 and Q3 is set from design geometry, and I do not feel that could do better job moving panels in quad.

There are some regular alignment issues with this detector; if I tune nicely (with precision ~ pixel size) rings in the middle of radial range,

then internal and external rings may be misaligned. This may be due to small tilt of the detector or non-accounted z position of panels

w/o optical metrology.

Results

Resulting geometry for this data looks like on attached image.

All files are available under

- /reg/g/psdm/detector/alignment/epix10ka2m/calib-mfx-epix10ka2m-01-2018-11-15/2019-05-06-geometry-alignment/

Recommendation for further geometry improvement

The only reliable procedure to get correct detector geometry is an 3-d optical metrology of entire detector.

After that one would need to adjust precisely

1) detector center relative to image with rings

2) sample-to-detector distance

3) detector plane tilts.

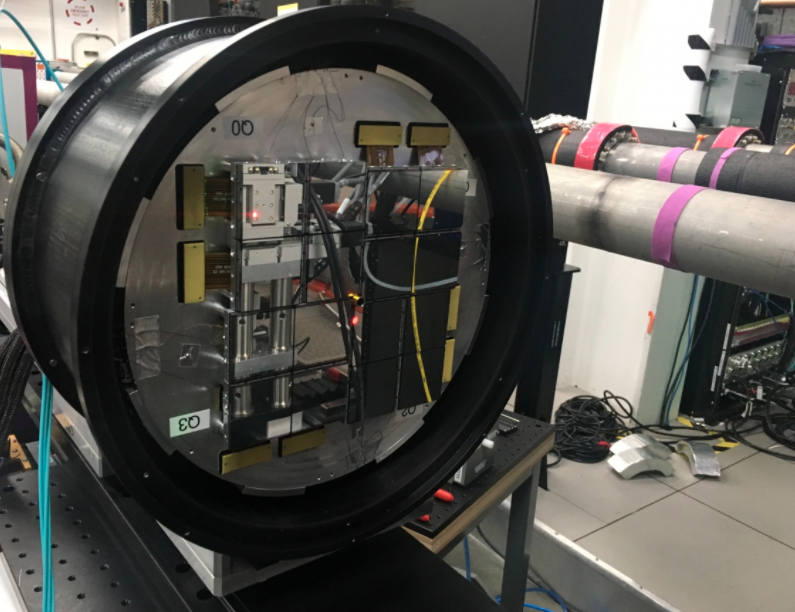

2020-06-25 New Optical Metrology

Hi Philip, Chris, and Mikhail,

My apologies for not getting this to you sooner.

Additional apologies in that the order we took the measurements in

is rotated from our "standard" and we were unable to set the origin

to zero. In the picture the XPP mounting bars on on the left side and

so this would be UP.

A map of the sensor corners measurement ordering and the quad

number locations is attached along with a picture of the setup. The

origin (not 0-0-0) is in the upper left of the picture.

Along with the Excel spreadsheet.

Please ask questions as I know this can be confusing.

Thanks,

Chris

X-Y quality check for optical metrology measurements

----------------------------------------------------------------------------------------------------------------------------

segm: S1 S2 dS1 dS2 L1 L2 dL1 dL2 angle(deg) D1 D2 dD d(dS) d(dL)

----------------------------------------------------------------------------------------------------------------------------

segm: 0 36699 36691 -477 -485 39689 40683 -558 436 0.68576 54051 54789 -737 8 -994

segm: 1 36702 36696 -483 -489 39683 39678 439 434 0.70171 54044 54063 -19 6 5

segm: 2 36716 36681 -72 -107 39693 39650 70 27 0.12926 54018 54068 -49 35 43

segm: 3 36690 36705 -405 -390 39713 39684 390 361 0.57368 54070 54058 11 -15 29

segm: 4 36718 36692 388 362 39723 39746 -323 -300 0.54072 54121 54069 51 26 -23

segm: 5 36702 36703 332 333 39721 39701 -306 -326 0.47973 54069 54083 -13 -1 20

segm: 6 36599 36701 594 696 39702 39700 -631 -633 0.93077 54012 54065 -53 -102 2

segm: 7 36664 36664 369 369 39714 39708 -343 -349 0.53238 54046 54054 -7 0 6

segm: 8 36677 36713 -412 -376 39744 39682 420 358 0.56842 54092 54055 36 -36 62

segm: 9 36695 36728 -338 -305 39744 39719 319 294 0.46362 54104 54090 13 -33 25

segm:10 36702 36736 -263 -229 39708 39568 371 231 0.35558 54087 53980 106 -34 140

segm:11 36725 36688 -614 -651 39683 39703 596 616 0.91292 54086 54055 30 37 -20

segm:12 36706 36692 476 462 39668 39671 -429 -426 0.67736 54050 54040 10 14 -3

segm:13 36672 36714 523 565 39697 39708 -512 -501 0.78501 54064 54069 -5 -42 -11

segm:14 36705 36692 538 525 39731 39700 -479 -510 0.76673 54078 54082 -3 13 31

segm:15 36696 36695 473 472 39712 39699 -421 -434 0.68179 54076 54062 13 1 13

----------------------------------------------------------------------------------------------------------------------------

WARNING segm 0: |-737| > 60.0

WARNING segm 0: |-994| > 60.0

WARNING segm 6: |-102| > 60.0

WARNING segm 8: |62| > 60.0

WARNING segm 10: |106| > 60.0

WARNING segm 10: |140| > 60.0

Z quality check for optical metrology measurements

-----------------------------------------------------------------------------------------------------------------------------------------

segm: SA LA XSize YSize dZS1 dZS2 dZL1 dZL2 dZSA dZLA ddZS ddZL dZX dZY angXZ(deg) angYZ(deg) dz3(um)

-----------------------------------------------------------------------------------------------------------------------------------------

segm: 0 36695 40186 36695 40186 44 248 54 258 146 156 -204 -204 146 156 0.22796 0.22242 -202.642

segm: 1 36699 39680 36699 39680 85 115 -30 0 100 -15 -30 -30 100 -15 0.15612 -0.02166 -30.010

segm: 2 36698 39671 36698 39671 146 274 23 151 210 87 -128 -128 210 87 0.32786 0.12565 -128.163

segm: 3 36697 39698 36697 39698 171 109 1 -61 140 -30 62 62 140 -30 0.21858 -0.04330 62.067

segm: 4 36705 39734 39734 36705 8 89 26 107 48 66 -81 -81 66 48 0.09589 0.07571 80.991

segm: 5 36702 39711 39711 36702 -71 -149 204 126 -110 165 78 78 165 -110 0.23806 -0.17172 -77.894

segm: 6 36650 39701 39701 36650 0 14 24 38 7 31 -14 -14 31 7 0.04474 0.01094 14.000

segm: 7 36664 39711 39711 36664 -14 -42 123 95 -28 109 28 28 109 -28 0.15727 -0.04376 -27.981

segm: 8 36695 39713 36695 39713 235 111 0 -124 173 -62 124 124 173 -62 0.27012 -0.08945 124.224

segm: 9 36711 39731 36711 39731 84 152 -20 48 118 14 -68 -68 118 14 0.18416 0.02019 -67.912

segm:10 36719 39638 36719 39638 76 220 -241 -97 148 -169 -144 -144 148 -169 0.23094 -0.24428 -143.077

segm:11 36706 39693 36706 39693 82 103 -2 19 92 8 -21 -21 92 8 0.14438 0.01227 -21.083

segm:12 36699 39669 39669 36699 36 199 79 242 117 160 -163 -163 160 117 0.23181 0.18344 163.008

segm:13 36693 39702 39702 36693 75 42 85 52 58 68 33 33 68 58 0.09885 0.09135 -33.110

segm:14 36698 39715 39715 36698 169 165 160 156 167 158 4 4 158 167 0.22794 0.26073 -3.817

segm:15 36695 39705 39705 36695 96 65 177 146 80 161 31 31 161 80 0.23305 0.12569 -30.939

-----------------------------------------------------------------------------------------------------------------------------------------

WARNING segm 0: |-202.6| > 100.0

WARNING segm 2: |-128.2| > 100.0

WARNING segm 8: |124.2| > 100.0

WARNING segm 10: |-143.1| > 100.0

WARNING segm 12: |163.0| > 100.0

Corrected points:

Quad 0

point X Y Z

#4 95420 -4982 158686

4 95420 -3988 158686

Quad 1

point X Y Z

#9 15847 43156 158511

9 15847 43054 158511

Quad 2

point X Y Z

#12 58727 123727 158774

12 58727 123587 158774

X-Y quality check for optical metrology measurements

----------------------------------------------------------------------------------------------------------------------------

segm: S1 S2 dS1 dS2 L1 L2 dL1 dL2 angle(deg) D1 D2 dD d(dS) d(dL)

----------------------------------------------------------------------------------------------------------------------------

segm: 0 36699 36691 -477 -485 39689 39689 436 436 0.69435 54051 54063 -11 8 0

segm: 1 36702 36696 -483 -489 39683 39678 439 434 0.70171 54044 54063 -19 6 5

segm: 2 36716 36681 -72 -107 39693 39650 70 27 0.12926 54018 54068 -49 35 43

segm: 3 36690 36705 -405 -390 39713 39684 390 361 0.57368 54070 54058 11 -15 29

segm: 4 36718 36692 388 362 39723 39746 -323 -300 0.54072 54121 54069 51 26 -23

segm: 5 36702 36703 332 333 39721 39701 -306 -326 0.47973 54069 54083 -13 -1 20

segm: 6 36701 36701 696 696 39702 39700 -631 -633 1.00435 54082 54065 16 0 2

segm: 7 36664 36664 369 369 39714 39708 -343 -349 0.53238 54046 54054 -7 0 6

segm: 8 36677 36713 -412 -376 39744 39682 420 358 0.56842 54092 54055 36 -36 62

segm: 9 36695 36728 -338 -305 39744 39719 319 294 0.46362 54104 54090 13 -33 25

segm:10 36702 36736 -263 -229 39708 39708 231 231 0.35496 54087 54082 4 -34 0

segm:11 36725 36688 -614 -651 39683 39703 596 616 0.91292 54086 54055 30 37 -20

segm:12 36706 36692 476 462 39668 39671 -429 -426 0.67736 54050 54040 10 14 -3

segm:13 36672 36714 523 565 39697 39708 -512 -501 0.78501 54064 54069 -5 -42 -11

segm:14 36705 36692 538 525 39731 39700 -479 -510 0.76673 54078 54082 -3 13 31

segm:15 36696 36695 473 472 39712 39699 -421 -434 0.68179 54076 54062 13 1 13

----------------------------------------------------------------------------------------------------------------------------

WARNING segm 8: |62| > 60.0

Z quality check for optical metrology measurements

-----------------------------------------------------------------------------------------------------------------------------------------

segm: SA LA XSize YSize dZS1 dZS2 dZL1 dZL2 dZSA dZLA ddZS ddZL dZX dZY angXZ(deg) angYZ(deg) dz3(um)

-----------------------------------------------------------------------------------------------------------------------------------------

segm: 0 36695 39689 36695 39689 44 248 54 258 146 156 -204 -204 146 156 0.22796 0.22520 -204.009

segm: 1 36699 39680 36699 39680 85 115 -30 0 100 -15 -30 -30 100 -15 0.15612 -0.02166 -30.010

segm: 2 36698 39671 36698 39671 146 274 23 151 210 87 -128 -128 210 87 0.32786 0.12565 -128.163

segm: 3 36697 39698 36697 39698 171 109 1 -61 140 -30 62 62 140 -30 0.21858 -0.04330 62.067

segm: 4 36705 39734 39734 36705 8 89 26 107 48 66 -81 -81 66 48 0.09589 0.07571 80.991

segm: 5 36702 39711 39711 36702 -71 -149 204 126 -110 165 78 78 165 -110 0.23806 -0.17172 -77.894

segm: 6 36701 39701 39701 36701 0 14 24 38 7 31 -14 -14 31 7 0.04474 0.01093 14.001

segm: 7 36664 39711 39711 36664 -14 -42 123 95 -28 109 28 28 109 -28 0.15727 -0.04376 -27.981

segm: 8 36695 39713 36695 39713 235 111 0 -124 173 -62 124 124 173 -62 0.27012 -0.08945 124.224

segm: 9 36711 39731 36711 39731 84 152 -20 48 118 14 -68 -68 118 14 0.18416 0.02019 -67.912

segm:10 36719 39708 36719 39708 76 220 -241 -97 148 -169 -144 -144 148 -169 0.23094 -0.24385 -143.925

segm:11 36706 39693 36706 39693 82 103 -2 19 92 8 -21 -21 92 8 0.14438 0.01227 -21.083

segm:12 36699 39669 39669 36699 36 199 79 242 117 160 -163 -163 160 117 0.23181 0.18344 163.008

segm:13 36693 39702 39702 36693 75 42 85 52 58 68 33 33 68 58 0.09885 0.09135 -33.110

segm:14 36698 39715 39715 36698 169 165 160 156 167 158 4 4 158 167 0.22794 0.26073 -3.817

segm:15 36695 39705 39705 36695 96 65 177 146 80 161 31 31 161 80 0.23305 0.12569 -30.939

-----------------------------------------------------------------------------------------------------------------------------------------

WARNING segm 0: |-204.0| > 100.0

WARNING segm 2: |-128.2| > 100.0

WARNING segm 8: |124.2| > 100.0

WARNING segm 10: |-143.9| > 100.0

WARNING segm 12: |163.0| > 100.0

References