Integration sequence:

- Loaded Modules on Rings

- Welding, QC testing

- Load Services into ¼-shell

- Transfer ¼-shell to integration tooling

- Load Rings into ¼-shell

- Transfer Rings to integration tooling

- Integrate Rings into ¼-shell

- Welding, QC testing

- Integrate two ¼-shells

- QC testing

- Package, ship

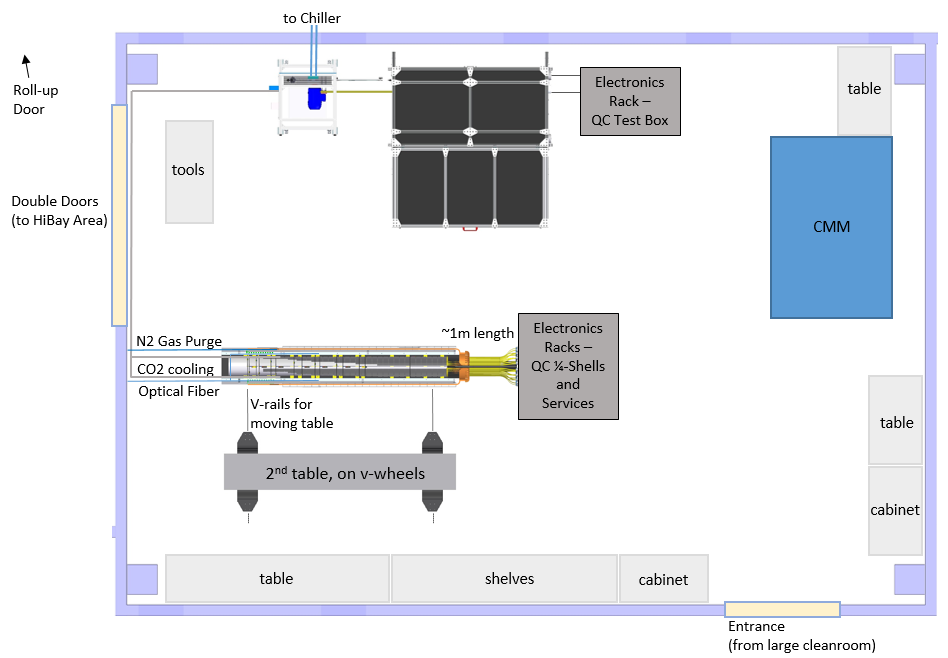

19-0 1/4-shells in B33 cleanroom:

Past presentation: Integration Tooling and Plan at SLAC 8 Nov 2021.pptx

Next steps:

- Prepare for 19-0 (Drafting - setup with dummy rings and linear slide)

- Finalize design/drawings of tables

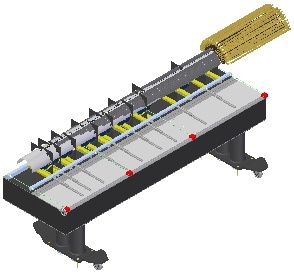

Linear Rail

Selection of a linear rail to test for 19-0/1.

Requirements (preliminary):

- Cleanroom compatible

- Load: ~1kg

- weight of loaded Ring and HF (~1kg, not in SE)

- operator load - handling/sliding linear rail

- installing HF onto rail fixture while extended - robust to operator error

- Range: ~0.4m (retracted) to ~0.9m (extended)

- extend by at least 0.5m (to make ring engage far side 1/4-shell)

- retracted length ~0.4m (to not overhang edge of table)

- Precision:

- Line up threaded holes in Ring with thru holes in 1/4-shell

- 2mm pins, 2.4mm clearance holes → ~0.4mm dia. clearance shared between assembly and manufacturing tolerances

- 19-0/1 prototype: linear rail, HF bolted on. no other adjustment. unbolt/rebolt to make small adjustments via oversized holes

- Bolt together, slide in rail, check misalignment, slide out rail, adjust if required

- Bolt together, install taper pins, slide in rail, install fasteners

- Line up threaded holes in Ring with thru holes in 1/4-shell