Integration sequence:

- Loaded Modules on Rings

- Welding, QC testing

- Load Services into ¼-shell

- Transfer ¼-shell to integration tooling

- Load Rings into ¼-shell

- Transfer Rings to integration tooling

- Integrate Rings into ¼-shell

- Welding, QC testing

- Integrate two ¼-shells

- QC testing

- Package, ship

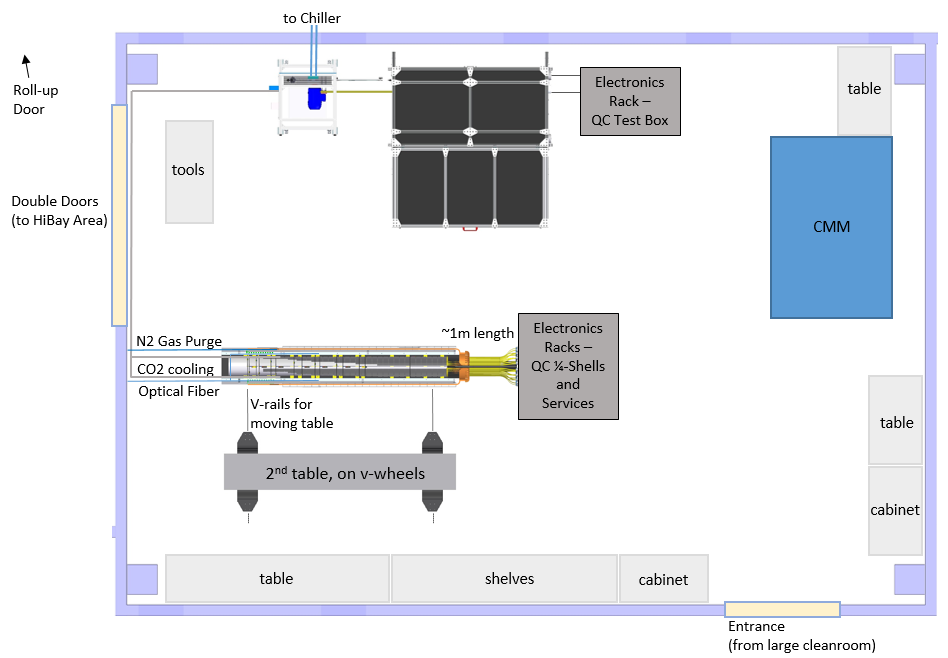

19-0 1/4-shells in B33 cleanroom:

Past presentation: Integration Tooling and Plan at SLAC 8 Nov 2021.pptx

Next steps:

- Prepare for 19-0 (Drafting - setup with dummy rings and linear slide)

- Finalize design/drawings of tables

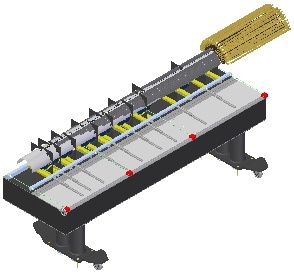

Linear Rail

Selection of a linear rail and bearing to test for 19-0/1.

Requirements (preliminary):

- Cleanroom compatible

- Load: operator handling loads

- weight of loaded Ring and HF (~1kg, not in SE)

- operator load - handling/sliding linear rail

- installing HF onto rail fixture while extended - robust to operator error

- Range: ~0.4m (retracted) to ~0.9m (extended)

- extend by at least 0.5m (to make ring engage far side 1/4-shell)

- retracted length ~0.4m (to not overhang edge of table)

- Precision:

- Line up threaded holes in Ring with thru holes in 1/4-shell

- 2mm pins, 2.4mm clearance holes → ~0.4mm dia. clearance shared between assembly and manufacturing tolerances

- 19-0/1 prototype: linear rail, HF bolted on. no other adjustment. unbolt/rebolt to make small adjustments via oversized holes

- Bolt together, slide in rail, check misalignment, slide out rail, adjust if required

- Bolt together, install taper pins, slide in rail, install fasteners

- Line up threaded holes in Ring with thru holes in 1/4-shell

- Usability:

- include handle

- include lock in "extended" position

- keep clear of fragile parts - work with covers etc.

- Travel needed:

- ~500mm to bring one side into contact with other side

- preserving space on table for welding/covers/etc on both sides of HF

- ~160mm to move one HF beyond edge of 1/4-shell

- ~500mm to bring one side into contact with other side

- Prototype 19-0/1 concept (following what was shown previously): ~500mm travel, ~400mm length

- 2x McMaster # 8379K6 , stacked

- Prototype 19-0/1 concept (following what was shown previously): ~500mm travel, ~400mm length

- Alternative: 1x ~250mm travel, ~400mm length rail per ring, to move both 1/4-shells and meet in the middle

- not preferred: less assembly flexibility, less clearance when connecting handling frame due to less travel

- Alternative: 1x ~450mm travel, move rails to edge of table so single rail can reach far side 1/4-shell

- not sure about rigidity cantilevered from bearing at one end, or about table space to enclose.

- Alternative: 1x ~250mm travel, ~400mm length rail per ring, to move both 1/4-shells and meet in the middle

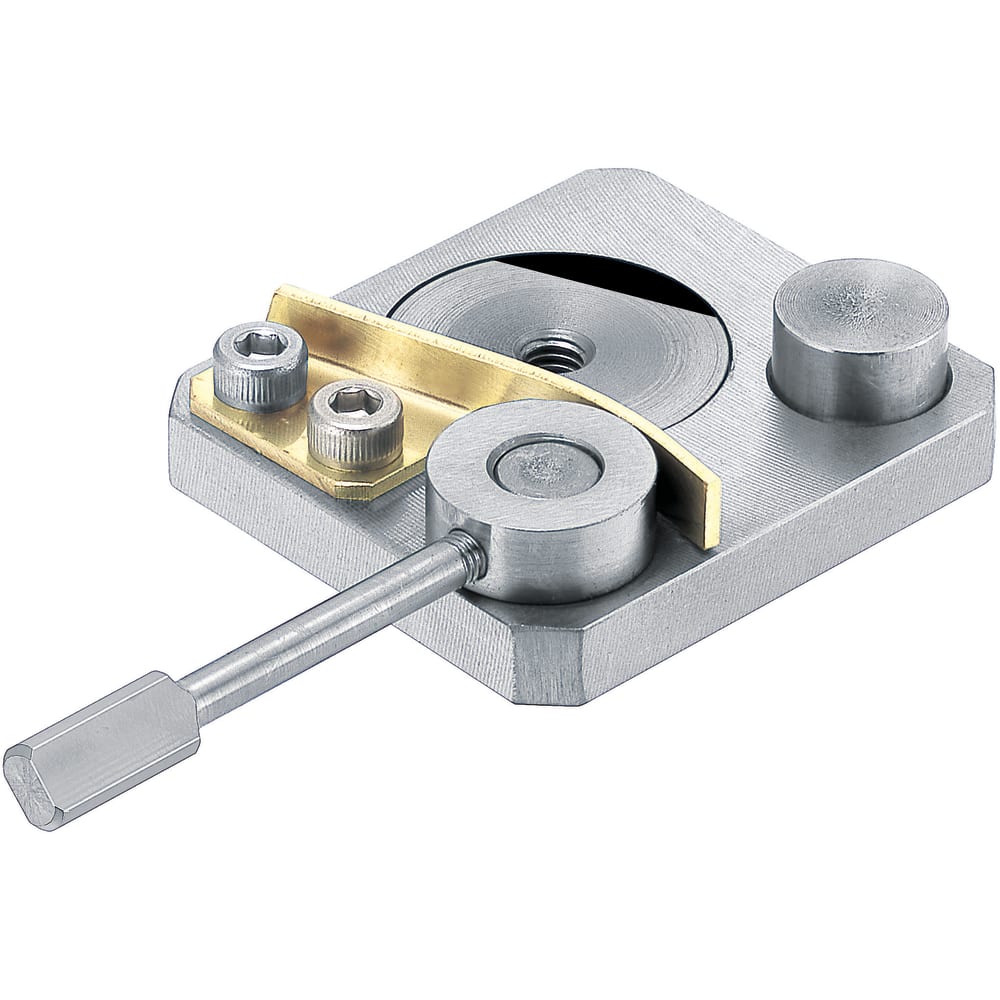

Candidate vendor parts:

- 8020 Inc. # 6516

- slide on 1.5" t-slot rail. add #6800 locking handle. not preferred due to sliding friction and height.

- Misumi # SSE2BWLZ14G-400

- linear rail w/ bearings, stainless steel, cleanroom grease.

- locking mechanism?

- Misumi SECWK14 compatible with above, but not stainless

- locking mechanism?

- also end stop bolts

- Grease not preferred (cleanliness / accidental spread)

- Igus Drylin NT

- plastic slides

- Sent request to Igus contact

Looking for:

- ~500mm linear motion

- ~400mm collapsed length

- ~10lb load capacity

- Low duty cycle (moved occasionally)

- End stops at both ends of travel

- For clean assembly room (ISO7) use

- Qty ~12 of these slides