The ePixUHR35kHz Megapixel Cameras project aims to provide modular detector blocks that can be configured into larger cameras in various structural configurations. The smallest building block is a 3x2 detector sensor module, which has a total of 3*2*192*168=193536≈200k pixels. Six of these (6*193536=1161216≈1M pixels) modules are assembled together into a 1 megapixel (1M) camera as shown below to the left. Four of the 1M cameras can then be assembled together, around a central beam pipe aperture, to form a 4M camera shown in the middle below. The largest configuration foreseen for this project is the 16M camera that consists of 16 of the 1M camera blocks as shown below on the right.

1 megapixel (1M)

6x 3x2 sensor modules:

- 6*3*2 = 36 ASICs

- 36*192*168 = 1,161,216 pixels

- 36*8 = 288 ASIC GT serial links

- 35 kfps: 288*1.975 = 568.8 Gbit/s

- 6 readout boards:

- 6 FPGAs & transceivers

- 6*12 = 72 fiber pairs

- 72*15 = 1080 Gbit/s

4 megapixel (4M)

4x 1M camera assemblies:

- 4*36 = 144 ASICs

- 144*192*168 = 4,644,864 pixels

- 144*8 = 1152 ASIC GT serial links

- 35 kfps: 1152*1.975 = 2275.2 Gbit/s

- 4*6 = 24 readout boards:

- 24 FPGAs & transceivers

- 24*12 = 288 fiber pairs

- 288*15 = 4320 Gbit/s

16 megapixel (16M)

16x 1M camera assemblies:

- 16*36 = 576 ASICs

- 576*192*168 = 18,579,456 pixels

- 576*8 = 4608 ASIC GT serial links

- 35 kfps: 4608*1.975 = 9100.8 Gbit/s

- 16*6 = 96 readout boards:

- 96 FPGAs & transceivers

- 96*12 = 1152 fiber pairs

- 1152*15 = 17280 Gbit/s

Table of contents

Useful resources

- Jira Kanban board for this project

- TID-ID Edge Computing Systems

- Presentations:

- Concept Design summary presentation (Sharepoint)

- Restricted Content

HE project related information

Mechanical design

Assembly procedure

- PowerPoint storyboard (work-in-progress as of 2024-05-02): LCLS-II HE Instrument - 1_4_16MPix Detector-StoryBoard.pptx

- Bill of materials

- Custom tools

- These are tools developed during the design to enable insertion and extraction of the

- 1MPix to/from 4MPix

- 3x2 carrier modules

- readout boards

- These are tools developed during the design to enable insertion and extraction of the

ASIC carrier module assembly

- TODO

- This needs a transport box that protects the ASIC and the sensor after it has been assembled!

- Contains the following components

- Carrier board

- 6x ePixUHR ASICs

Readout module assembly

- TODO

- Contains the following components

- Readout board

- Thermal interface pad

- Cooling block

- LEAP transceiver

- LEAP fiber pigtail

- Fiber holder

- These assemblies will be tested individually before mounting into the 1M assembly and also after mounting

- Write a test procedure for this

1M assembly

- The final product of this assembly is a complete and tested 1M block

- This involves attaching 6x of the following to the 1M cooling block

- ASIC carrier modules with ASICs and sensor (the most sensitive component)

- Readout modules with cooling blocks attached

4M assembly

- TODO

Toy model for inserting 1M module into the 4M crate

Thermal Design

1MP Sensor Module Thermal Analysis by Component

| Epoxy Layer Thickness | Strongback Pillar Diameter | Thermal Pad Thermal Conductivity | Thermal Pad Thickness |

|---|---|---|---|

1MP Prototype

Determine the effectiveness of the thermal plate in drawing heat away from a heat source

Check cooling lines effectiveness

PowerPoint Overview: 1MPPrototypeThermocoupleMeasurements.pptx

CAD: 1MPTile

Set-Up & Enclosure

Components

- 4-piece foam box enclosure (see 4MP Cam Thermal testing.pptx for more info)

- 1MP Assembly Tool

- LabJack T7 with CB37 Terminal Board (see LabJackT7SetUp.ipynb to use LabJack over USB)

- Variable Power Supply

- Chiller w/coolant & tubing

- 14x Type K Thermocouples

3x2 Detector Sensor Module

Components

36x ceramic heaters - 15 x 15 mm2 to thermally mimic ~150 W of heat dissipated by 1MP ASICs

6x aluminum plates to thermally mimic 1MP sensors & ASICs

6x fiberglass plates to thermally mimic 1MP sensor PCBs

6x aluminum strongbacks

Thermal Interfaces:

MX-4 Thermal Paste & 2-part epoxy to bond ceramic heaters to aluminum, aluminum to fiberglass, & fiberglass to strongbacks

6 Tflex™ 700 thermal pads 1 mm thick between aluminum strongbacks & copper thermal plate

- 1x copper thermal plate

- Cooling pipe - Copper OFE or Stainless Steel. Still TBD

Circuitry

See 1MPPrototypeHeaterCircuitSchematic.pptx for more details

30-40 V with 4.6-6.3 A over power supply, yielding 140-250 W of power

6x parallel connections, each with 6x heaters (6.0-6.5 Ohms each) in series

Thermal Analysis

- See 1MPSensorThermalResistanceAnalysisResults.pptx for more details

- As of 8/7/24, we expect to see 10.5 °C difference between the top of the aluminum plate and the inner surface of the thermal plate containing the cooling pipe using a 1-D thermal analysis

Readout Board

AS OF 8/7/24, THIS PART OF THE PROTOTYPE PROJECT IS ON HOLD, WAITING FOR FINALIZED COOLING PLATE DESIGN

Components

- 7x ceramic heaters - 15 x 15 mm2 to thermally mimic heat dissipated by FPGA & power regulators

- 5x ceramic heaters - 10 x 10 mm2 to thermally mimic heat dissipated by power regulators & LEAP transceiver

- Thermal Pads

- Copper Cooling Plate

Circuitry

- See 1MPPrototypeHeaterCircuitSchematic.pptx for more details

- 6.3-8.0 V with 8.5-10.8 A over power supply, yielding 54-87 W of power

- Power Resistors used in series to regulate heat dissipation of each sensor

Sensor design

The measurements below is based on the sensor design found in UHR_3x2_aug2024_overlay.GDS (restricted).

| Full sensor | Lower left corner | Between two ASICs at the bottom | Lower right corner | Between ASICs in the middle | Top left corner | Top right corner | |

|---|---|---|---|---|---|---|---|

| Image | |||||||

| Measurements |

|

|

|

|

|

|

|

Sensors for ASIC and systems characterization

There is a strong need to have sensors capable of detecting visible light during the characterization phase of the detector. This capability enables the use on lab, low power, LASER that can reproduce the fast timing and large charges that will be experienced during beam time use. X-ray sensor do have metallization in the entrance window to block visible light therefore existing sensor are not suitable

Solutions proposed

- Design mast on the 1x1 sensor in the production run

- It will take more than a year to have them and adds a step in the process, which adds risks to the production run

- Etch the metal away. Can be done in individual and prototype sensor (5x5mm)

- Only sensor for characterization would go through this step

- Can be done in existing sensor (have them available within a month)

- In the past we had issues removing the metal and CK's team will investigate this since it is believe this can be consistently done

- Decision is to make production runs with full metallization and process the sensors in house for characterization

Link to mechanical models: Dxf with the design

Electronics design for 3x2 sensor module

The electronics for the 3x2 sensor module is split into two parts; the ASIC carrier (left in the block diagram below) and the readout board (right in the block diagram). They are electrically connected together through a right-angle connector from the Samtec SEARAY connector family, which provides a total of 500 pins for signals and power. The ASIC carrier contains the 3x2 ASICs together with the 3x2 sensor and minimal amount of other components in order to reduce the size and therefore increase the sensitive area of the detector focal plane (the are which is covered by a sensitive sensor). All the active circuitry for interfacing and powering the ASICs is located on the readout board as well as the components for optical communication with the external back-end system.

More details about the electronics design for the 3x2 module can be found on a dedicated page: 3x2 Readout Overview

| ePixUHR35kfps 3x2 Assembly | ePixUHR35kfps 3x2 Readout Board | ePixUHR35kfps 3x2 ASIC Carrier Board | |

|---|---|---|---|

| 3D view | |||

| Altium 365 project | https://stanford-linear-accelerator-center.365.altium.com/designs/1C32F53F-0F7D-4FA6-A6A2-A68D0AD370D8 | ||

| Board tracking | N/A | PC_261_101_44_C00 | |

| Dimensions (X x Y) | TBD | 59mm x 160mm | 60.61mm x 42mm |

| STEP 3D model | ePixUHR35kfps-3x2-readout-board-PCB-2024-05-20.step | ePixUHR35kfps-3x2-ASIC-carrier-board-PCB-2024-05-16.step |

NOTE: If some of the images above are indicated as missing, please ensure that you are logged into Confluence and have access to the Board tracking pages where the images are stored.

Power

The system is designed to operate at 48 V nominally. There are separate supply connections for analog (APWR/AGND) and digital (DPWR/DGND) that are feeding different parts of the readout electronics, which can be used to have a low noise analog supply and a high-efficiency digital supply for example.

Power supplies

TODO, see TIDIDECS-109 - Getting issue details... STATUS

ePixUHR35kfps 1M Power Breakout Board

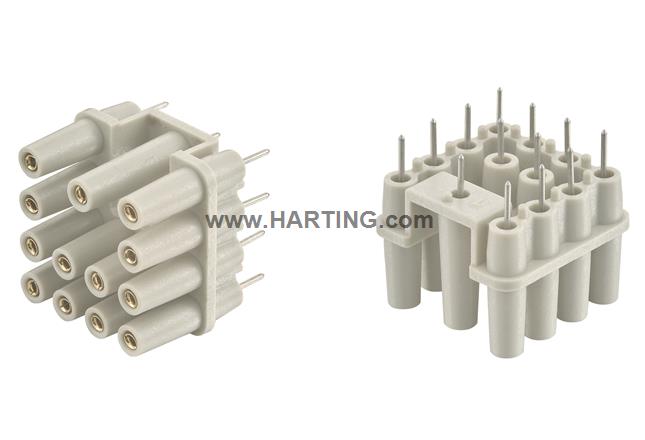

The 1M Power Breakout Board distributes the power to six 3x2 Readout Boards. It has two externally facing square Harting connectors, one for all the power and one for optional signals. Each power channel is individually fused with a socketed fuse to protect against catastrophic failures. Changing a fuse requires removal of the board from the 1M assembly, which has been done intentionally since blowing a fuse indicates something internal to the 1M assembly has gone wrong and requires expert investigation. The thermistor connections can be selected on the board through switches to which of the six 3x2 Readout Boards they connect to. Only one thermistor shall be connected per thermistor channel.

| Pin | Power connector (J1) | Signal connector (J2) - optional |

|---|---|---|

| 1 | Digital power (DPWR) | Timing input 0 (TIMING_IN_0) |

| 2 | Timing input 1 (TIMING_IN_1) | |

| 3 | Analog power (APWR) | Timing output 0 (TIMING_OUT_0) |

| 4 | Timing output 1 (TIMING_OUT_1) | |

| 5 | Digital ground (DGND) | Timing input 2 (TIMING_IN_2) |

| 6 | Digital ground (DGND) | |

| 7 | Analog ground (AGND) | Timing output 2 (TIMING_OUT_2) |

| 8 | Digital ground (DGND) | |

| 9 | Thermistor in (THERM_EXT_IN) | Spare connection (SPARE1) |

| 10 | Sensor ground (HV_GND) | Thermistor in (THERM_AUX_IN) |

| 11 | Thermistor out (THERM_EXT_OUT) | Spare connection (SPARE2) |

| 12 | Sensor biasing (SENSOR_HV) | Thermistor out (THERM_AUX_OUT) |

Board specific details

- See TIDIDECS-81 - Getting issue details... STATUS

- The "Top" side of the board is facing the rear of the camera

- The "Bottom" side of the board is facing the inside of the camera and connects to the six 3x2 readout boards through the TFM connectors

| PCB | Assembly with connectors | |

|---|---|---|

Top | ||

Bottom | ||

Altium 365 project | ||

Board tracking | - | |

Dimensions (X x Y) | 110 mm x 110 mm | - |

3D files | TODO |

Connectors and parts

The two square Harting connectors on the Power Breakout Board above is separated into one for power and one for signal. They have different gender to avoid wrong connections. The power connector have a "protected" female connector on the cable side where voltages may be exposed on the pins. The tables below lists the components that are needed to assembly a full connector stack for the power and signal.

Power connector J1

| Description | Harting part number | Quantity | DigiKey | Image |

|---|---|---|---|---|

| PCB connector Han Q12/0 PCB Adapter | 09 12 012 9901 | 1 | ||

| Male PCB adapter Han Q12-M for PCB-Adapter | 09 12 012 3002 | 1 | 1195-1378-ND | |

| Male pins for PCB adapter Han D-M-Kontakt f. Han Q12/0 LP-Adapter | 09 15 000 6191 | 12 | 1195-1575-ND | |

| Base flange Han 3A-HBM-SL | 09 20 003 0301 | 1 | 1195-1772-ND | |

| Female crimp housing Han 12Q-SMC-FI-CRT-PE with QL | 09 12 012 3101 | 1 | 1195-1379-ND | |

| Choose the crimp pins below to match the cable wire diameter (12 in total) | ||||

| Female crimp pins 2.5 mm² (14 AWG) | 09 15 000 6206 | x | 1195-1581-ND | |

| Female crimp pins 1.5 mm² (16 AWG) | 09 15 000 6201 | x | 1195-1576-ND | |

| Female crimp pins 1.0 mm² (18 AWG) | 09 15 000 6202 | x | 1195-1577-ND | |

| Female crimp pins 0.75 mm² (18 AWG) | 09 15 000 6205 | x | 1195-1580-ND | |

| Female crimp pins 0.5 mm² (20 AWG) | 09 15 000 6203 | x | 1195-1578-ND | |

| Female crimp pins 0.14 mm² - 0.37 mm² (22-26 AWG) | 09 15 000 6204 | x | 1195-1579-ND | |

Only one hood needed | ||||

| Metal hood (grey) Han A Hood Top Entry 2 Pegs M20 | 19 20 003 1440 | 1 | 1195-3067-ND | |

| Metal hood (red) Han 3A-gg-M20 red, M-version | 19 20 003 1446 | x | 1195-19200031446-ND | |

| Han A Hood Angled Entry 2 Pegs M20 | 19 20 003 1640 | x | 1195-3069-ND | |

| Choose the cable gland below to match the external diameter of the cable | ||||

| Han CGM-M M20x1,5 D.5-9mm | 19 00 000 5080 | x | 1195-3032-ND | |

| Han CGM-M M20x1,5 D.10-14mm | 19 00 000 5084 | x | 1195-3034-ND | |

| Han CGM-M M20x1,5 D.6-12mm | 19 00 000 5082 | x | 1195-3033-ND | |

| Han CGM-M M20x1,5 D.5-9mm/6-12mm | 19 00 000 5081 | x | 1195-3458-ND | |

Signal connector J2

| Description | Harting part number | Quantity | DigiKey | Image |

|---|---|---|---|---|

| PCB connector Han Q12/0 PCB Adapter | 09 12 012 9901 | 1 | ||

| Female PCB adapter Han Q12-F for PCB-Adapter | 09 12 012 3102 | 1 | 1195-1380-ND | |

| Female pins for PCB adapter Han D F-ontact f. Han Q12/0 PCB adapter | 09 15 000 6297 | 12 | 09150006297-ND | |

| Base flange Han 3A-HBM-SL | 09 20 003 0301 | 1 | 1195-1772-ND | |

| Male crimp housing Han 12Q-SMC-MI-CRT-PE with QL | 09 12 012 3001 | 1 | 1195-1377-ND | |

| Choose the crimp pins below to match the cable wire diameter (12 in total) | ||||

| Male crimp pins 2.5 mm² (14 AWG) | 09 15 000 6106 | x | 1195-1565-ND | |

| Male crimp pins 1.5 mm² (16 AWG) | 09 15 000 6101 | x | 1195-1560-ND | |

| Male crimp pins 1.0 mm² (18 AWG) | 09 15 000 6102 | x | 1195-1561-ND | |

| Male crimp pins 0.75 mm² (18 AWG) | 09 15 000 6105 | x | 1195-1564-ND | |

| Male crimp pins 0.5 mm² (20 AWG) | 09 15 000 6103 | x | 1195-1562-ND | |

| Male crimp pins 0.14 mm² - 0.37 mm² (22-26 AWG) | 09 15 000 6104 | x | 1195-1563-ND | |

Only one hood needed | ||||

| Metal hood Han A Hood Top Entry 2 Pegs M20 | 19 20 003 1440 | 1 | 1195-3067-ND | |

| Metal hood (red) Han 3A-gg-M20 red, M-version | 19 20 003 1446 | x | 1195-19200031446-ND | |

| Han A Hood Angled Entry 2 Pegs M20 | 19 20 003 1640 | x | 1195-3069-ND | |

| Choose the cable gland below to match the external diameter of the cable | ||||

| Han CGM-M M20x1,5 D.5-9mm | 19 00 000 5080 | x | 1195-3032-ND | |

| Han CGM-M M20x1,5 D.10-14mm | 19 00 000 5084 | x | 1195-3034-ND | |

| Han CGM-M M20x1,5 D.6-12mm | 19 00 000 5082 | x | 1195-3033-ND | |

| Han CGM-M M20x1,5 D.5-9mm/6-12mm | 19 00 000 5081 | x | 1195-3458-ND | |

Optional parts

Some optional parts that might be useful in some cases.

| Description | Harting part number | DigiKey | Image | Drawing |

|---|---|---|---|---|

| Cover with seal (gray) for female insert Han 3A Protect Cover, Sealing Die Cast f | 09 20 003 5425 | 1195-1792-ND | ||

Cover without seal (gray) for male insert | 09 20 003 5426 | 1195-1793-ND | ||

| Cover with seal (blue) for female insert Han Ex-C for HCC Han 3A with seal | 09 36 003 5409 | 09360035405-ND | ||

| Cover without seal (blue) for male insert Han Ex-C for HCC Han 3A | 09 36 003 5410 | 09360035410-ND |

Tools

The pins that attach to the wires on the cable are crimped and required a specific tool for it listed below. A pin removal/extraction tool could also be useful in case a pin was inserted into the wrong slot.

| Description | Harting part number | DigiKey | Image | Drawing |

|---|---|---|---|---|

| Small removal tool Removal Tool, Han D, Mini | 09 99 000 0052 | |||

| Larger removal tool Removal Tool Han D | 09 99 000 0012 | |||

| Universal crimp tool Han Hand Crimp Tool | 09 99 000 0110 | |||

| Simple crimp tool Han CRIMP TOOL WITH LOCATOR | 09 99 000 0021 |

Power cable

See TIDIDECS-258 - Getting issue details... STATUS

Fiber

See TIDIDECS-267 - Getting issue details... STATUS

ASIC

The ePixUHR 100 kHz ASIC is used in this project. The main properties are:

- 192 (H) x 168 (V) pixels

- 100 um x 100 um pixel size

- 8 serial data outputs operating at up to ~6 Gbit/s

Resources:

- Confluence page (restricted)

- Glue used to bond the ASIC+SENSOR to the carrier board

- SP-120 silicone primer: https://nusil.avantorsciences.com/nusil/en/product/SP-120/silicone-primer

- CV-2943 thermally conductive, controlled volatility RTV silicone: https://nusil.avantorsciences.com/nusil/en/product/CV-2943/thermally-conductive-controlled-volatility-rtv-silicone

Size and measurements

These measurements are taken from a GDS file (ePixUHR_100kHz_4Julie.gds) that was opened in KLayout.

| Full matrix | Lower left corner | Lower right corner | |

|---|---|---|---|

| Image | |||

| Measurements |

|

|

|

Block diagrams of camera configurations

The block diagrams have been created with Draw.io instead of the Gliffy integration in Confluence, which has major issue as soon as there are more than 100 items in the diagram it seems. It slows down the whole confluence page and it's near impossible to edit the diagram. There are also major limitations in the tools available in Gliffy, e.g. there doesn't seem to be a way to draw an arbitrary polygon or parallelograms.

Project Management

- Smartsheet

- PM Internal discussions

- LCLS-II-HE XES Detectors ePixHR10k PDR: https://indico.slac.stanford.edu/event/8884/