These are the new instructions for how to use the gas jets. This procedure will supersede the "How to use gas jets" and "How to DPS with gas jets" pages.

Hardware requirements:

- Gas bottle of selected gas species. Needs to have >1200psi if you plan to run the jets that high

- N2 available in the 6 pack if you plan to run with H2

- Regulator - there are multiple available

- 100 to 1200 psiG (max 3000psiG, but we only run up to 1200)

- -30psiG - ?? psi (for low pressure, and the ability to run to real 0, not 0 psiG

Step-by-step guide

Prepare the DPS system

- Verify both US-DPS and DS-DPS pumps are running and operating as normal.

- Also check VPIO:LI20:3164 to ensure the ion pump is on.

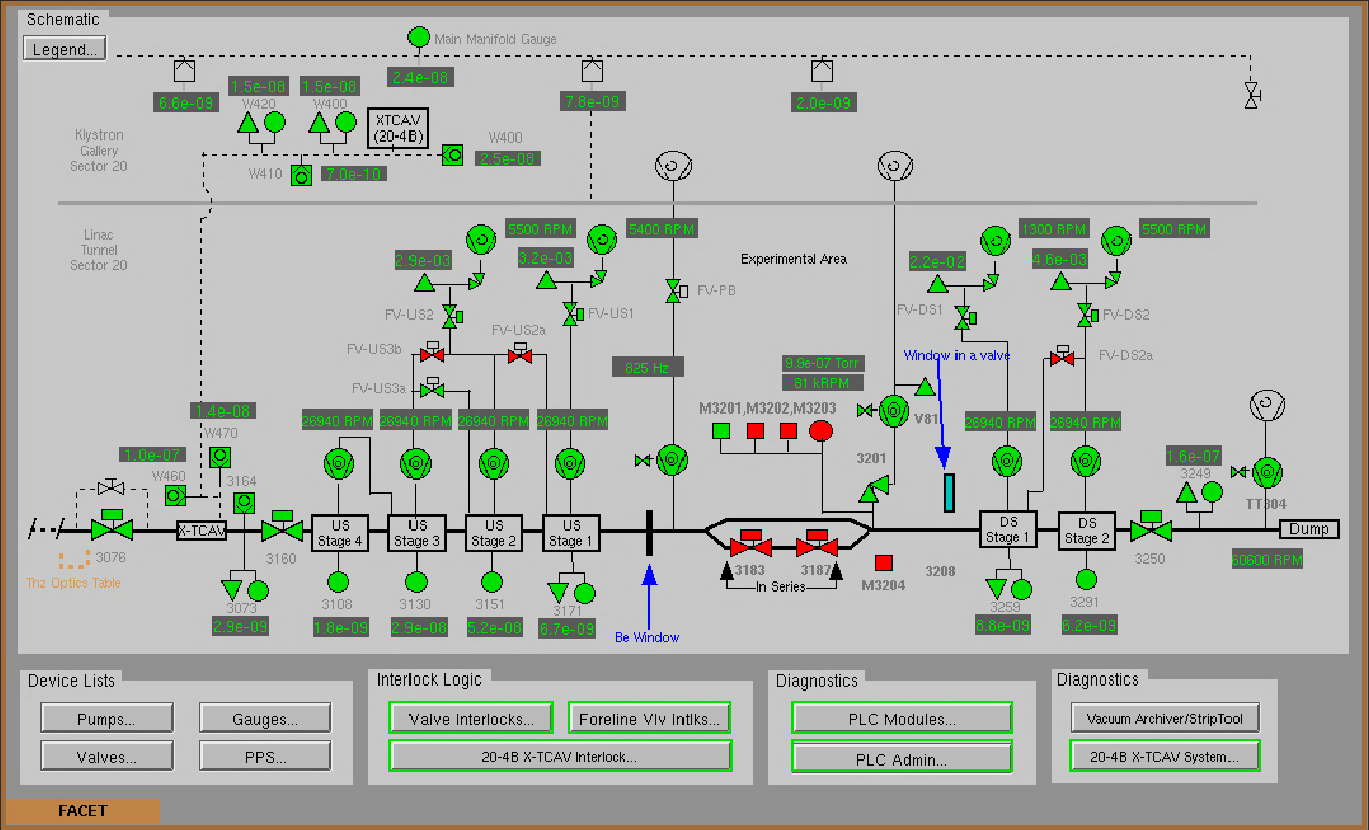

- Figure 1 shows how the DPS looks under nominal operation.

- Start a strip tool and load the file: DPS_Gasjet_Pressures.stp

- Find the VGCM:LI20:M3203:PMONRAW pressure - this is the 10 Torr capacitance manometer gauge that will provide the IP pressure.

- Ensure the 10 Torr CM gauge is zeroed: VGCM:LI20:M3203:P should be reading 0 Torr on the strip chart.

- If not - this must be zeroed using the rack controller.

- If not - this must be zeroed using the rack controller.

- Find the VGCM:LI20:M3203:PMONRAW pressure - this is the 10 Torr capacitance manometer gauge that will provide the IP pressure.

- Leave the downstream Be window OPEN, this will help

- NOTE - this advice could change after the full characterization of the gas jet if it is found to be more beneficial to close the window.

- NOTE - this advice could change after the full characterization of the gas jet if it is found to be more beneficial to close the window.

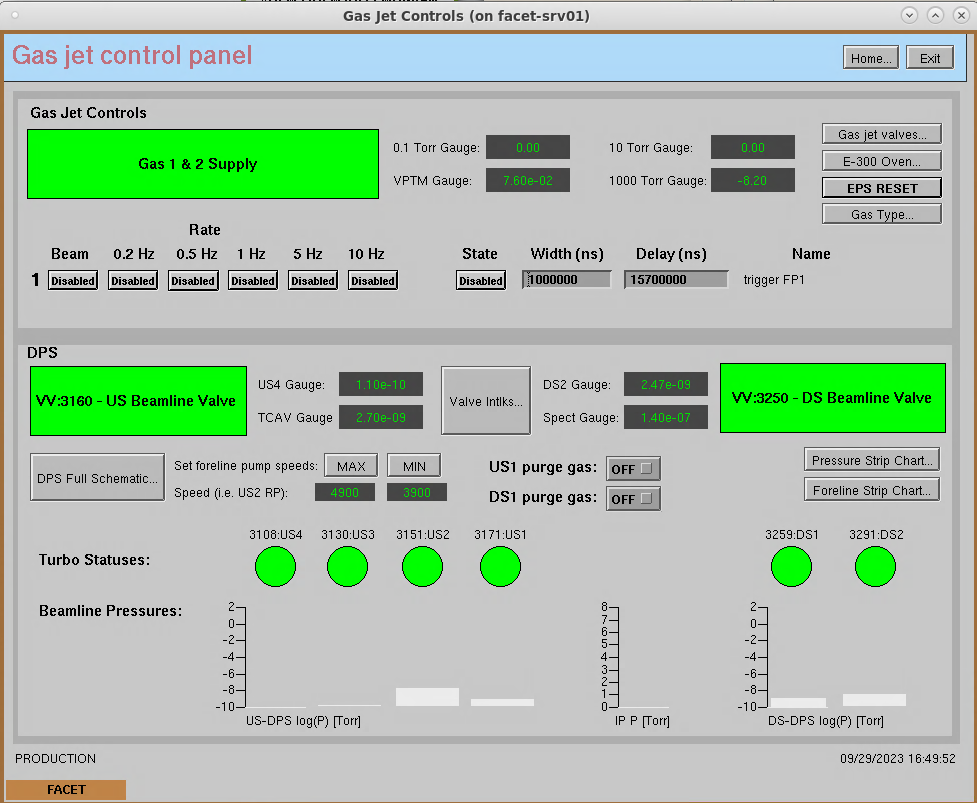

- Open the gas jet control panel from facethome: LI20 → Experiment → Gas Jet Controls... (Figure 2)

- Ensure the "Gas 1&2 supply" is green - this tell us that the EPS has not faulted. If it is red, try clearing the fault by hitting "EPS RESET". More details on the interlock statuses can be found in the "E300 Oven..." page

- Set the foreline pump speeds to MAX

- Set the gas type to Helium. There is no calibration curve for hydrogen, so use helium for both He or H2.

- If using hydrogen gas, then set the US1 and DS1 purge gas valves to ON (you will need to open the N2 gas bottle in the gallery later on)

- In the gallery:

- Zero the 10 Torr capacitance manometer gauge if necessary.

- If using hydrogen: Start the purge gas flowing - open the nitrogen 6 pack main valve and ensure that there is ~10 PSIG pressure on the regulator. Check the other in-line valves are open

- You can verify the flow is flowing by opening: DPS Full Schematic → US1 and DS1 roughing pumps → More..., and read the "N2 Flow" PV. It should be reading ~4 Pa.m3/s

- You can verify the flow is flowing by opening: DPS Full Schematic → US1 and DS1 roughing pumps → More..., and read the "N2 Flow" PV. It should be reading ~4 Pa.m3/s

- Prepare the gas delivery - next section.

Figure 1: Nominal vacuum state, before gas jet operations

Figure 2: Gas jet control panel

Prepare the gas delivery

How to operate the jet

How to reduce pressure or get into safe state to move the gas jet assembly

How to shut down after gas jet operation at end of shift or before changing gas species

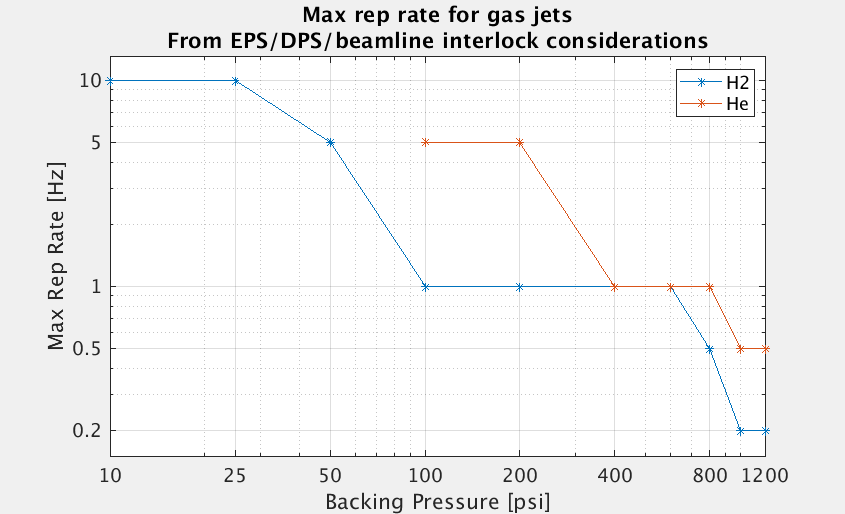

Maximum operating rates

Information needs to be updated for the present gas jet conditions

The following chart was acquired 07/15/2023, but with the timing width = 10ms, and no purge gas on the DPS. So this is now obsolete, but included for reference.