Outline

- Ring Loading Tooling, 19-1 RD53a

- Handling Frame, 19-1 RD53a OB Stave

- Shipping Box, 19-1 RD53a OB Stave

- Stave Loading Tooling, 19-1 RD53a OB Stave

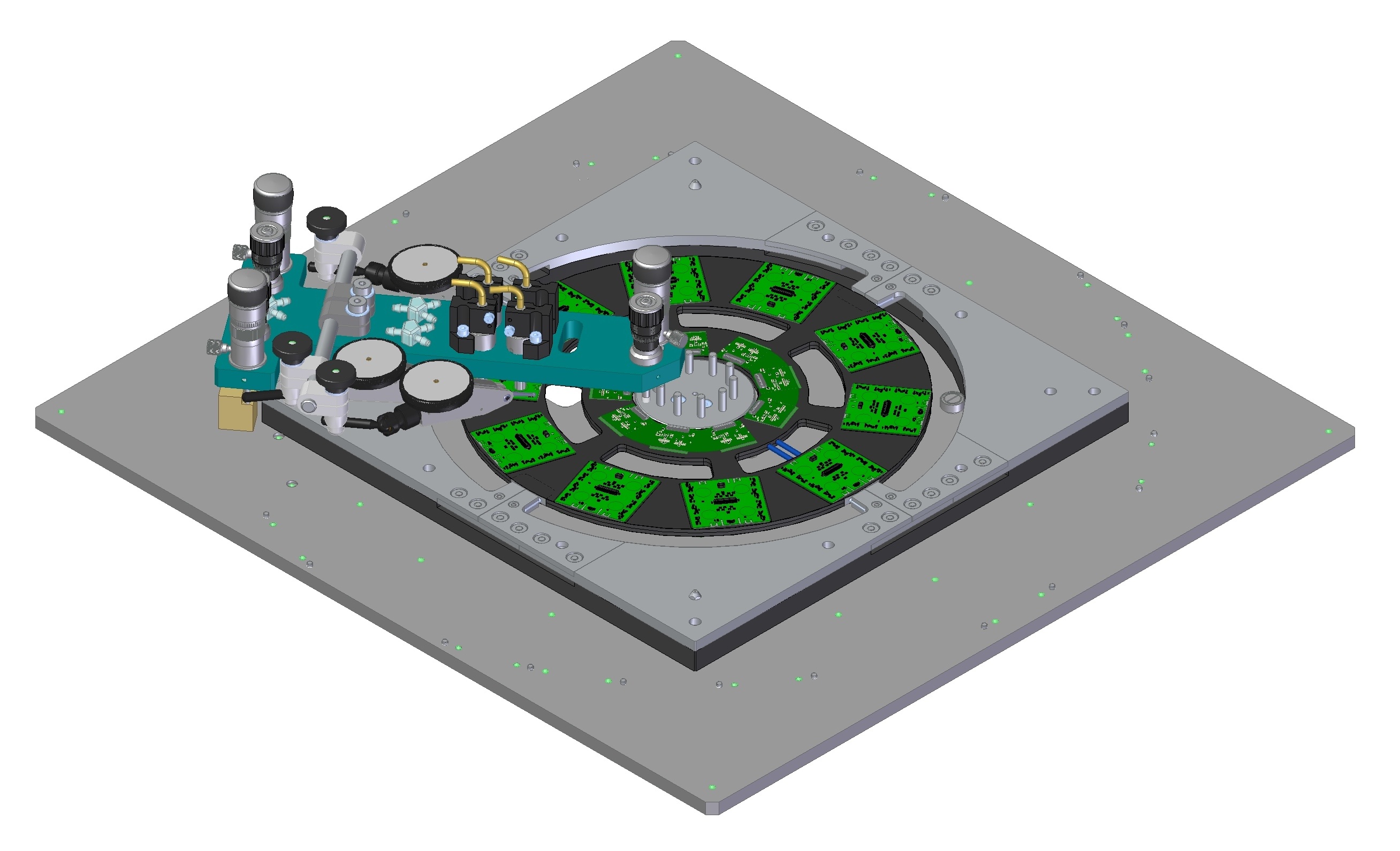

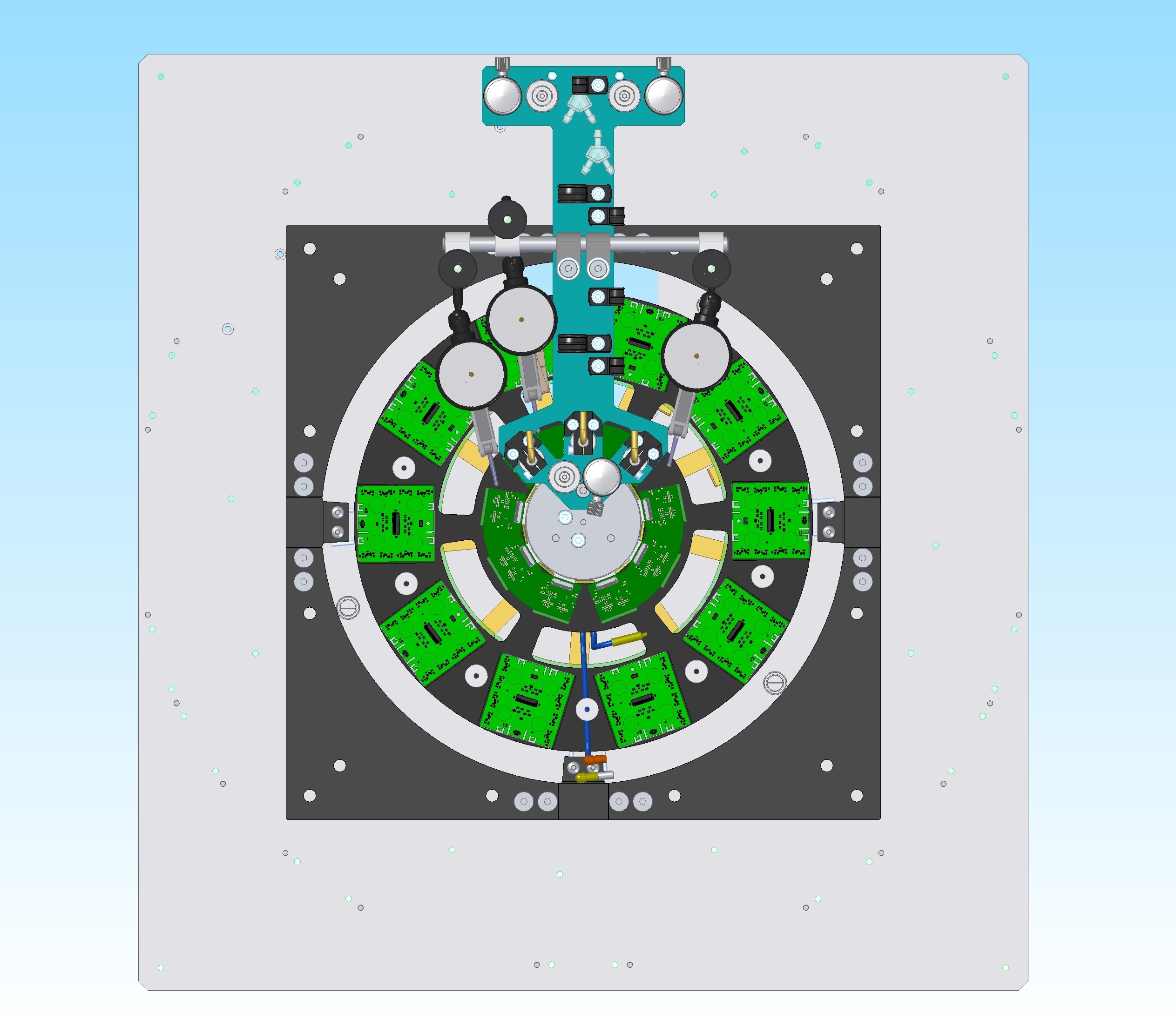

Ring Loading Tooling

Ring loading glue locations drawing (not released): REF-000160474 (LOADING FIXTURE, 19-1 RING).pdf

Ring Loading Tooling Drawings: 19-1 Ring.zip

- In the future, review drawings in Mechanics meeting and release/add to Windchill CAD library, to reduce risk of interface issues.

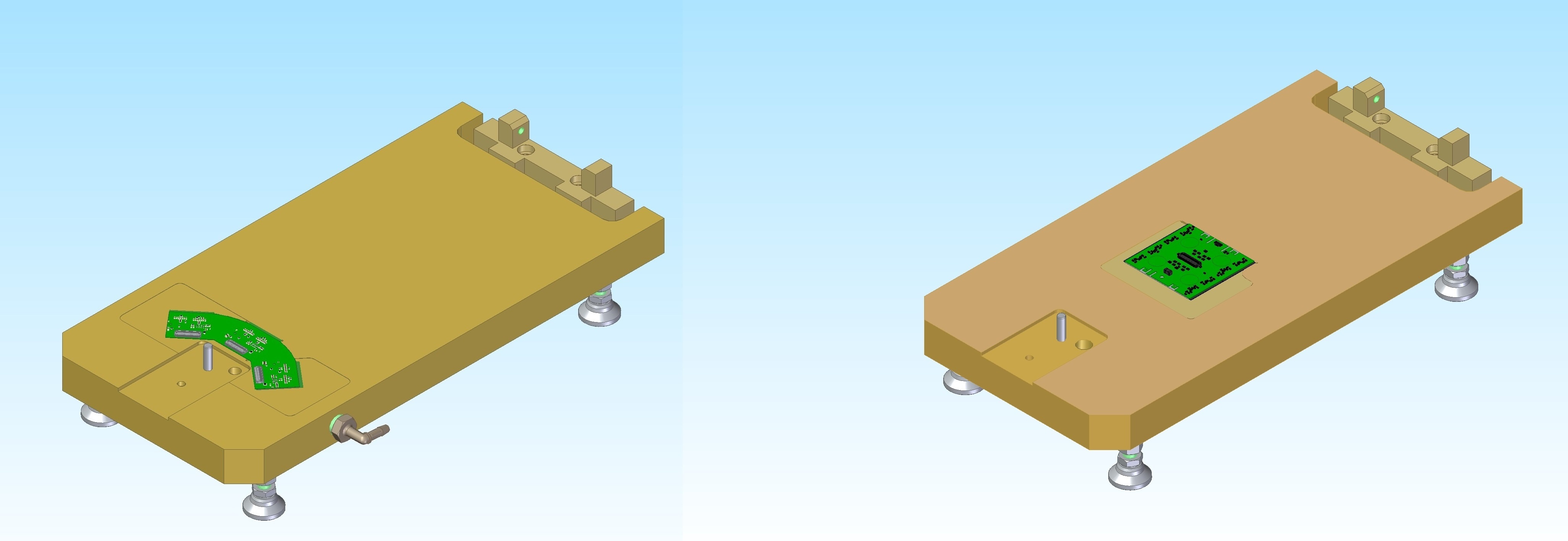

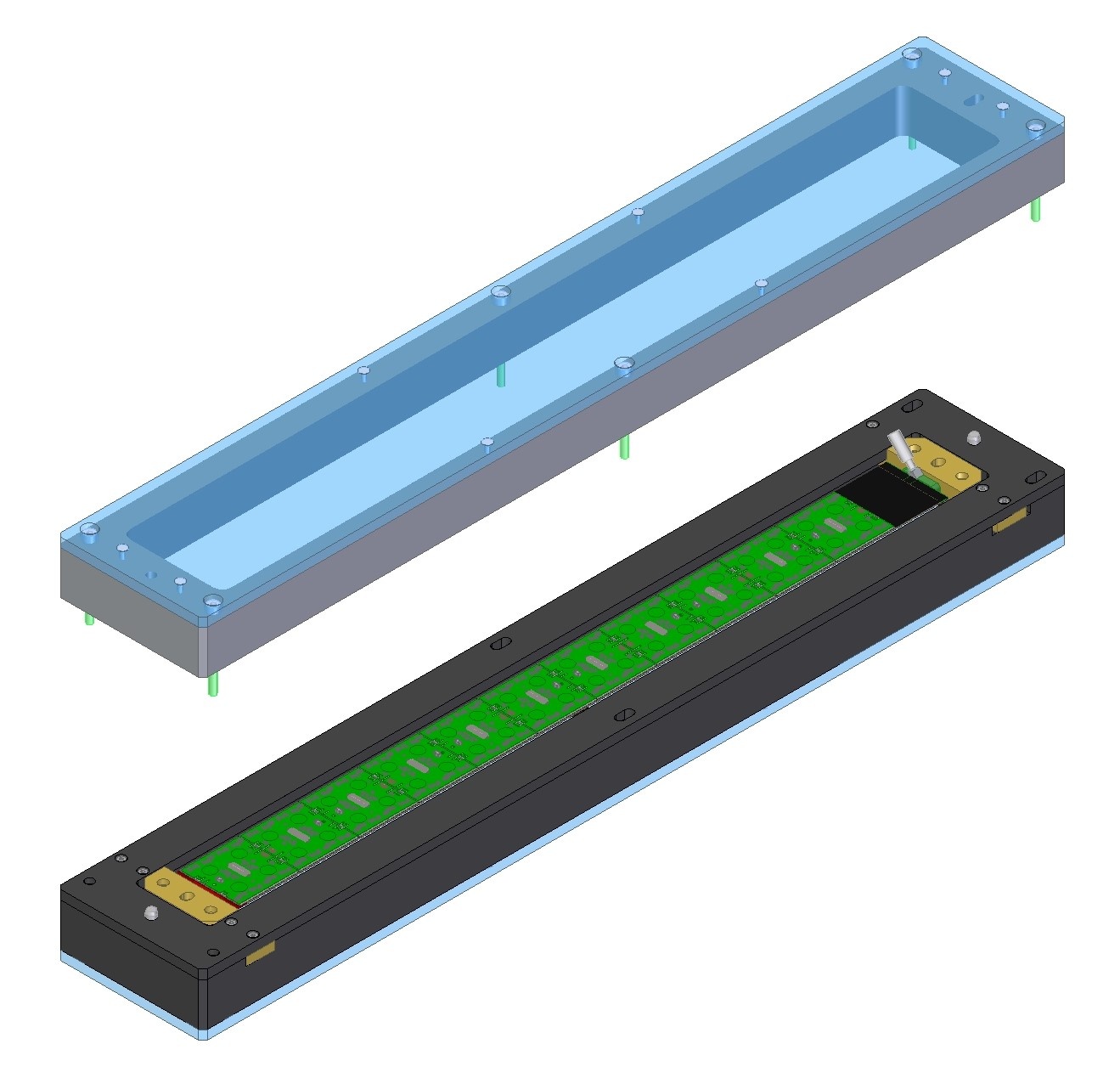

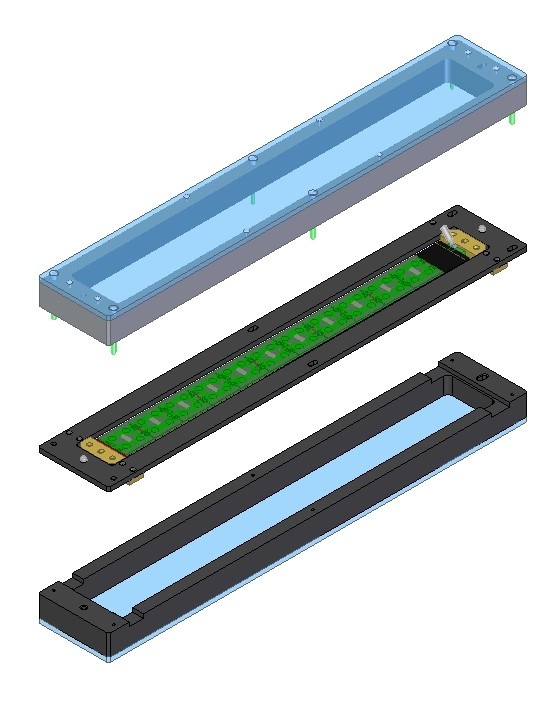

Handling Frame and Shipping Box

Handling Frame and Shipping Box added for Stave. Drawings created (not released).

Drawings (not released):

Handling Frame:

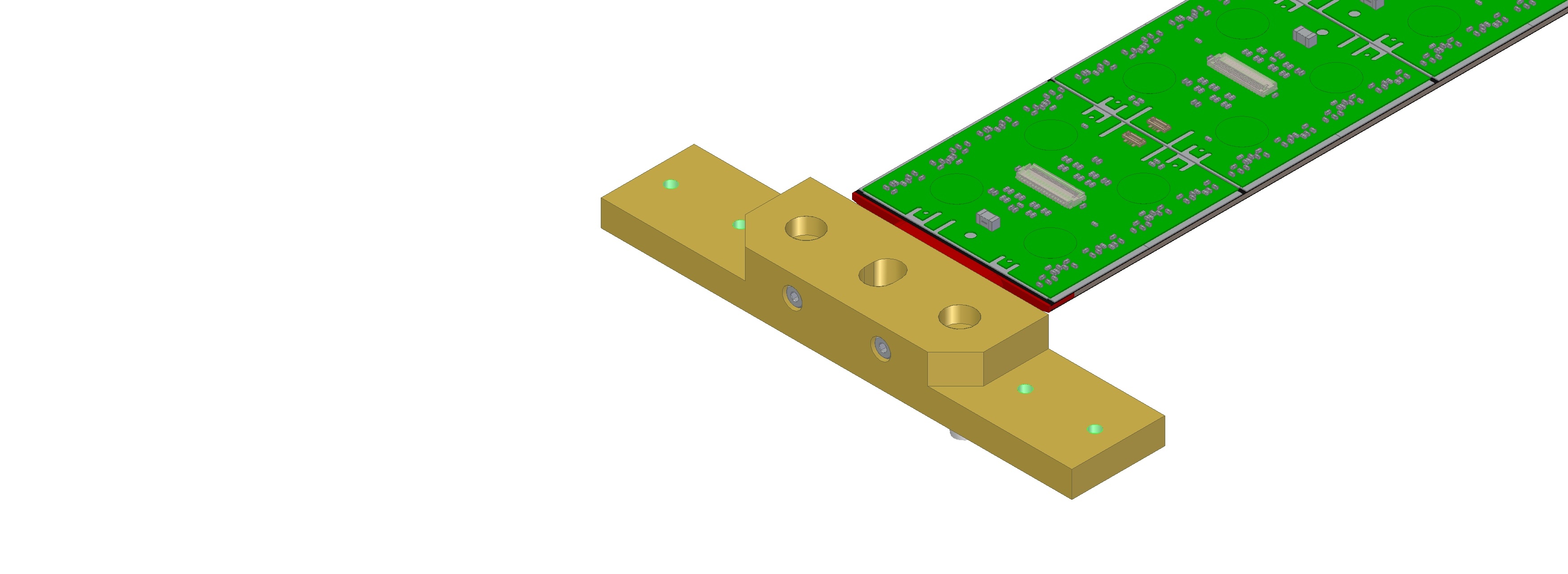

Interface block to join Stave and Handling Frame (not released):

Shipping Box:

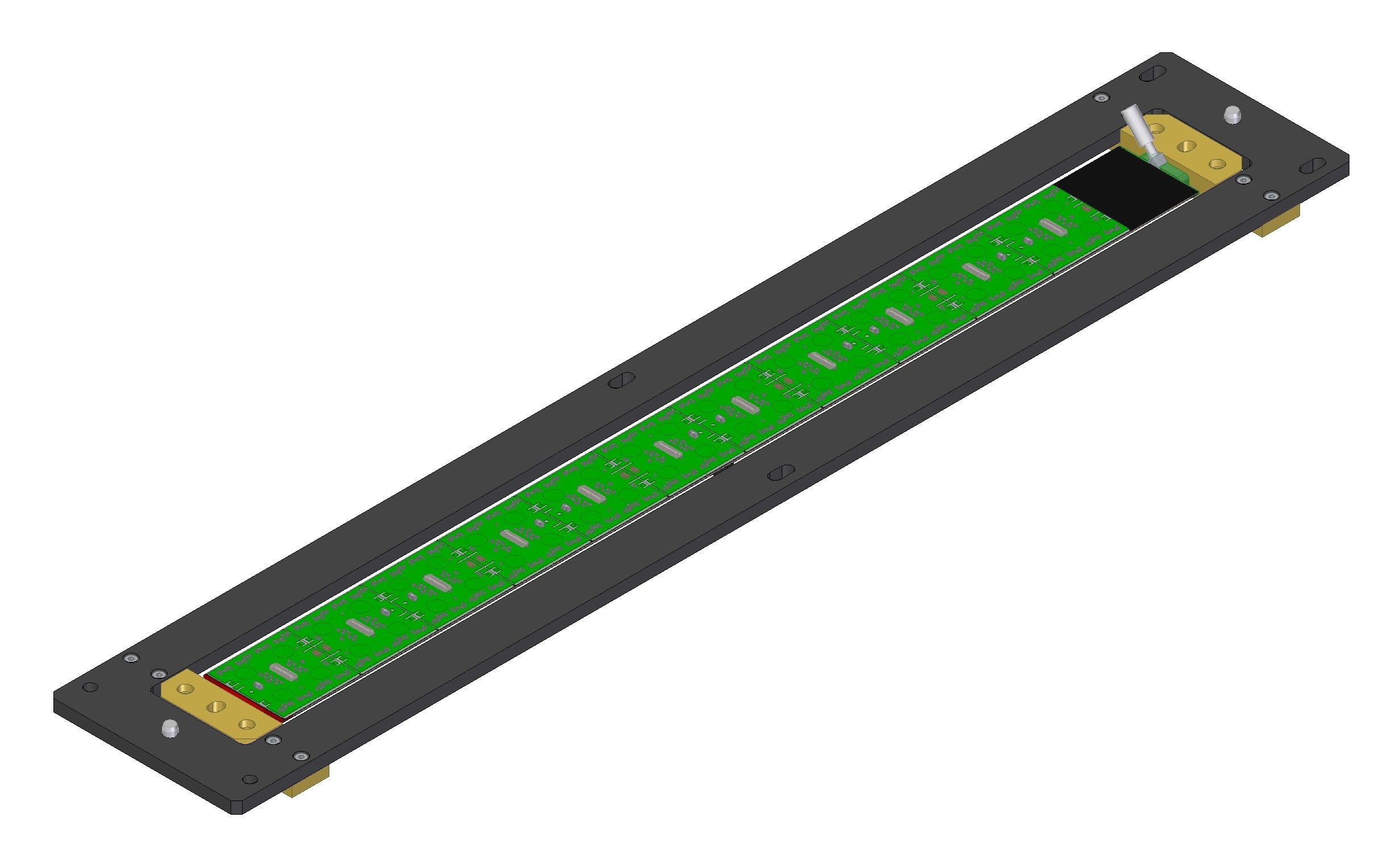

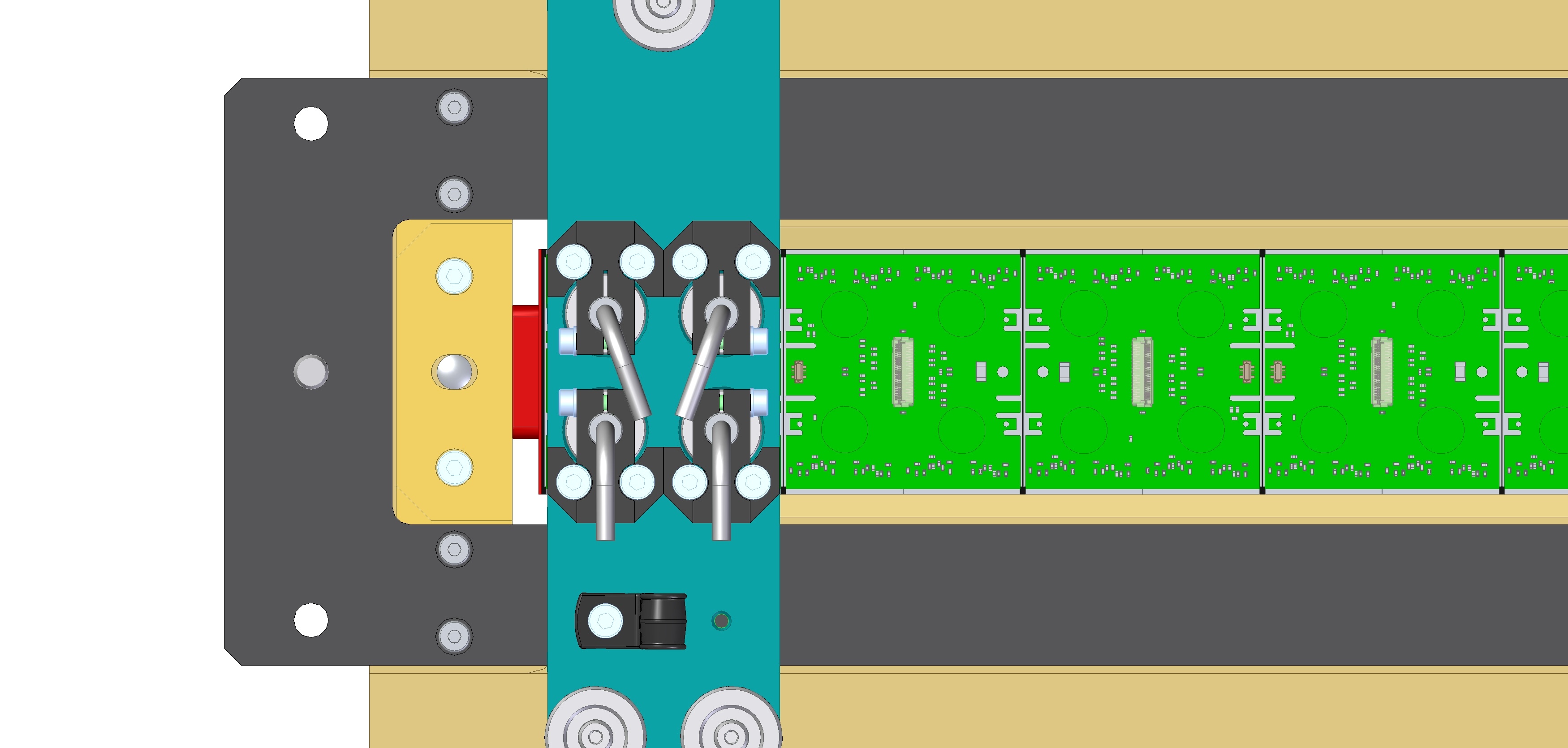

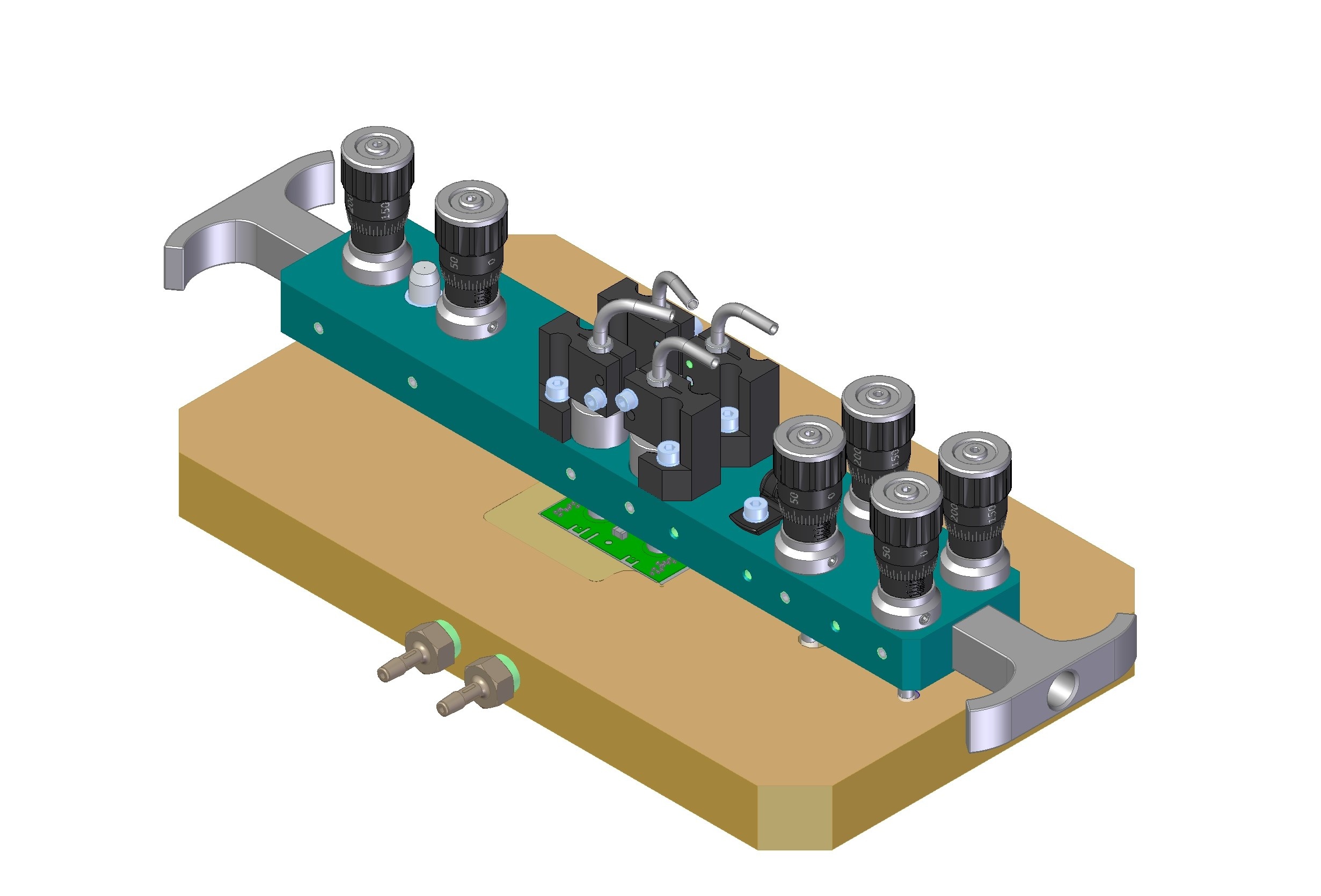

Stave Loading Tooling

A design/drawings were made in 2020 (Version 1, deprecated, not released): 19-1 STAVE LOADING TOOLING DRAWINGS 15DEC2020.pdf

- V1 does not include lessons learned more recently.

- Changes for V2: add 2nd set of adjusters, stepped pins, adjustable vacuum pads, handles.

Version 2, revised, Stave Loading Tooling drawings in progress. Drafts (not released) for baseplate (precision pins) and assemblies.

Stave Loading drawing drafts (not released):

- Top Leve Assembly: REF-000202041 (LOADING FIXTURE ASSY, 19-1 OB STAVE).pdf

- Baseplate: REF-000203575 (BASEPLATE AND PINS, LOADING FIXTURE, OB STAVE, 19-1, V2).pdf

- Loading Bridge: REF-000202287 (LOADING BRIDGE, FIXTURE, 19-1 OB STAVE).pdf

Loading Tooling:

Summary of requirements for loading 19-1 Outer Barrel Stave:

- Load RD53a Quad modules (drawings: 150um, 400um) with connectors oriented as shown in picture above

- Load modules onto 19-1 OB Stave (no drawing yet, preliminary CAD on LBL Windchill site)

- Load without collisions: 200um nominal gap / 100 micron minimum gap between modules (no assembly drawing yet showing modules on stave)

- Glue layer thickness to be 100um -50/+100um

- ESD protection during loading: grounding of tooling

- Mechanical protection of wire bonds during loading: stay clear of wire bonds, handle modules using tooling only, consider covers/shields

- Baseplate to be installed onto glue robot: weight limit 7kg (per manual)

- Stave to be removed from baseplate and transferred to test box for QC testing

Summary of different requirements for loading 19-1 Inner Barrel Stave:

- Load Triplet modules (drawing, .step)

- Load onto 19-1 IB Stave (no drawing yet, preliminary CAD on LBL Windchill site)

- Load without collisions: 200um nominal gap / 100 micron minimum gap between modules (no assembly drawing yet showing modules on stave)

Summary of specifications:

- Closely toleranced pins/bushings – same approach as used for 19-0 tooling

- Requirement: +/-75um module position tolerance in local support coordinate system (per requirements document "ITk Pixel Module Loading Accuracy Requirements" AT2-IP-ES-006-v3)

- Distribute tolerances:

- +/-50um module position relative to loading tooling baseplate coordinate system (to avoid collisions with 100um gap between modules).

- Dowel pins in baseplate – two per module location.

- Bridge to have bushing and slot for precision fit onto dowel pins.

- +/-25um local support position relative to loading tooling baseplate coordinate system (to accurately place modules to meet +/-75um requirement).

- Dowel pin in baseplate – to accurately locate one end of the Stave in Z.

- Tooling to fasten to mounting features on ends of Stave.

- +/-50um module position relative to loading tooling baseplate coordinate system (to avoid collisions with 100um gap between modules).

- Glue with beads to control glue layer thickness

- 100um dia beads, for ~75um glue layer thickness on carbon fiber.

- Loading tooling does NOT control the glue layer thickness.

- Loading bridge to rest on the module's pickup areas (vacuum pad locations) during gluing.

- Loading bridge to have micrometer adjusters to level the tool relative to the baseplate – to apply pressure at all vacuum pad locations during gluing.

- Loading bridge to have micrometer adjusters to level the tool relative to the pickup table – to make good contact between vacuum pads and module.

- Vacuum pads to pick up modules

- Vacuum pads to fit within clear areas on modules.

- Height adjustment of vacuum pads while on pickup table.

- Vacuum to securely hold modules.

- Tolerances:

- Module position relative to loading tooling baseplate (need +/-.050mm):

- Dowel pins: 6mm OD, h7 tolerance. (Misumi MSH6-60)

- Bushings: 6mm ID, G6 tolerance. (Misumi JBAUN8-20)

- Module position relative to loading tooling baseplate (need +/-.050mm):

| Tolerance Item | Where Used | Tolerance (mm, Dia.) |

Pick-up Table Edge Repeatability (for successive modules) | Locating Module to Pickup Table | .012 |

| Bridge Bushing ID | Locating Loading Bridge to Pick-up Table | .012 |

| Pick-up Table Pin OD | Locating Loading Bridge to Pick-up Table | .012 |

| Pin Location | Locating Loading Bridge to Pick-up Table | .020 |

| Bridge Bushing ID | Locating Loading Bridge to Loading Fixture | .012 |

| Baseplate Pin OD | Locating Loading Bridge to Loading Fixture | .012 |

| Pin Location | Locating Loading Bridge to Loading Fixture | .020 |

Total: | .100mm (+/-.050mm) | |

| Root Sum Square: | .039mm (+/-.019mm) |

- Stave position relative to loading tooling baseplate (need +/-.025mm):

| Tolerance Item | Where Used | Tolerance (mm, Dia.) |

| Pin Location | Locating Stave to Baseplate | .025 |

Pick-up Table Edge Accuracy (absolute position) | Locating Module to Pick-up Table *choose loading tooling baseplate coordinate system to line up with 1st module *this item affects all modules equally so does not affect gap/distance between modules | .025 |

Total: | .050mm (+/-.025mm) |

- Total for all:

- Limit: +/-.075mm

- Root sum square: +/-.026mm

Some past presentations:

- 30 March 2021: Tooling and Plans for Loading, 19-0/1, Stave and Ring