Why do I think that 2020-02-25 optical metrology is good

- very good quality check

- all z-measurements are around 1 feet, have a lit of repeatable numbers - can't be trusted

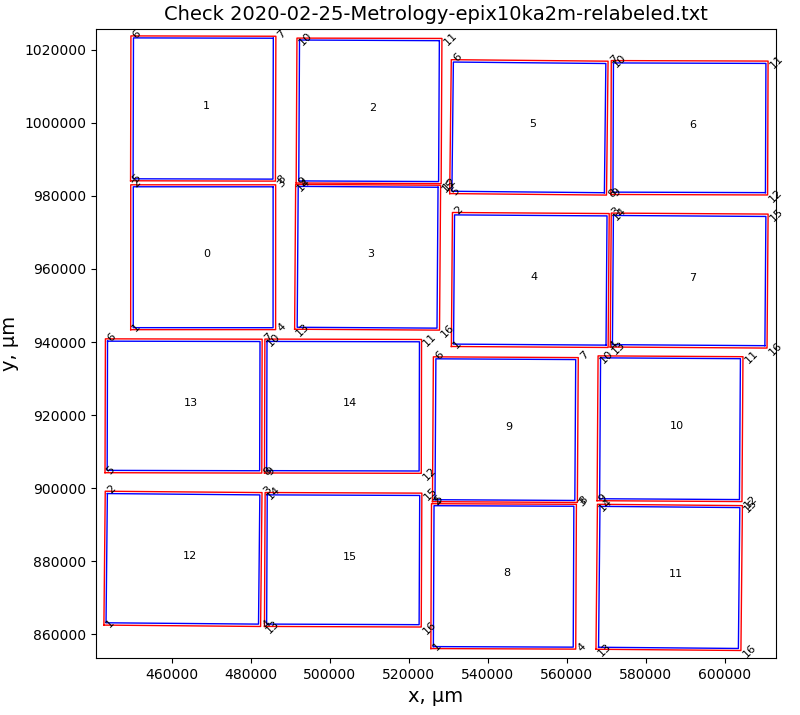

Quality check for original optical metrology from 2020-02-25

X-Y quality check for optical metrology measurements ---------------------------------------------------------------------------------------------------------------------------- segm: S1 S2 dS1 dS2 L1 L2 dL1 dL2 angle(deg) D1 D2 dD d(dS) d(dL) ---------------------------------------------------------------------------------------------------------------------------- segm: 0 36697 36688 18 9 39685 39676 9 0 -0.01949 54057 54032 24 9 9 segm: 1 36672 36696 90 114 39690 39688 -93 -95 -0.14725 54046 54045 0 -24 2 segm: 2 36703 36700 202 199 39695 39782 -183 -96 -0.28908 54127 54060 67 3 -87 segm: 3 36683 36700 260 277 39677 39695 -243 -225 -0.38763 54060 54039 20 -17 -18 segm: 4 36710 36693 -274 -291 39685 39687 270 272 -0.40785 54063 54049 14 17 -2 segm: 5 36686 36679 -408 -415 39699 39688 406 395 -0.59396 54065 54036 29 7 11 segm: 6 36684 36676 -134 -142 39693 39693 115 115 -0.19920 54036 54055 -18 8 0 segm: 7 36696 36705 -287 -278 39693 39706 256 269 -0.40771 54066 54064 1 -9 -13 segm: 8 36675 36684 162 171 39688 39674 -146 -160 -0.24041 54037 54036 1 -9 14 segm: 9 36679 36678 232 231 39671 39683 -220 -208 -0.33429 54034 54034 0 1 -12 segm:10 36679 36682 253 256 39677 39694 -240 -223 -0.36743 54044 54039 5 -3 -17 segm:11 36693 36701 367 375 39714 39690 -343 -367 -0.53539 54057 54075 -17 -8 24 segm:12 36677 36682 -378 -373 39671 39686 340 355 -0.54221 54038 54037 0 -5 -15 segm:13 36670 36681 -108 -97 39685 39679 98 92 -0.14800 54035 54034 0 -11 6 segm:14 36683 36671 -96 -108 39693 39664 104 75 -0.14729 54029 54036 -7 12 29 segm:15 36686 36677 -163 -172 39690 39677 169 156 -0.24184 54046 54034 11 9 13 ---------------------------------------------------------------------------------------------------------------------------- WARNING segm 2: |67| > 60.0 WARNING segm 2: |-87| > 60.0

Optical metrology processed by script v0 (with quads) and v1 (without quads)

- red rectangles - for points measured in optical metrology

- blue rectangles - panels reconstructed from geometry file

DAQ panel indexes in optical metrology possible detector orientations

DAQ panel indexes in optical metrology possible orientations

rot = 0 ^y

Q0 1 3 | 4 5 Q1

0 2 | 6 7

---------+----------> x

15 14 | 10 8

Q3 13 12 | 11 9 Q2

rot = 1 ^y

Q3 13 15 | 0 1 Q0

12 14 | 2 3

---------+----------> x

11 10 | 6 4

Q2 9 8 | 7 5 Q1

rot = 2 ^y

Q2 9 11 | 12 13 Q3

8 10 | 14 15

---------+----------> x

7 6 | 2 0

Q1 5 4 | 3 1 Q0

rot = 3 ^y

Q1 5 7 | 8 9 Q2

4 6 | 10 11

---------+----------> x

3 2 | 14 12

Q0 1 0 | 15 13 Q3

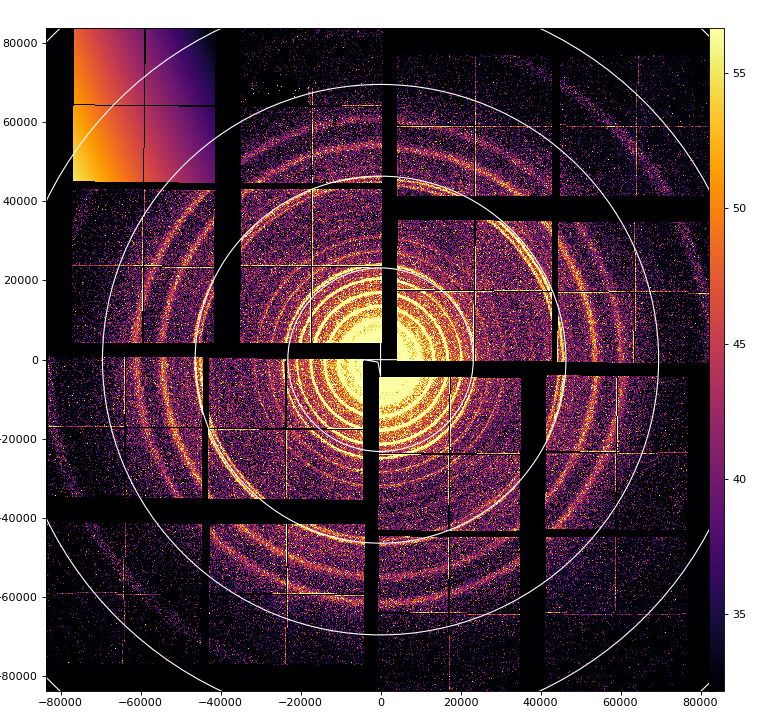

Images of panels in data for all detector orientations in metrology processing v1 without quads

- v1 of the metrology processing script represents simplest approach - each panel coordinates are taken as is to insert in the detector

- data from mfxc00118 run44 silver-behenate sample

Summary:

- numeration of quads at rotation looks symmetric - so seems right

- one orientation of the detector gives correct image and it shows smallest offsets between panels in quads

mfxc00118 run44 silver-behenate

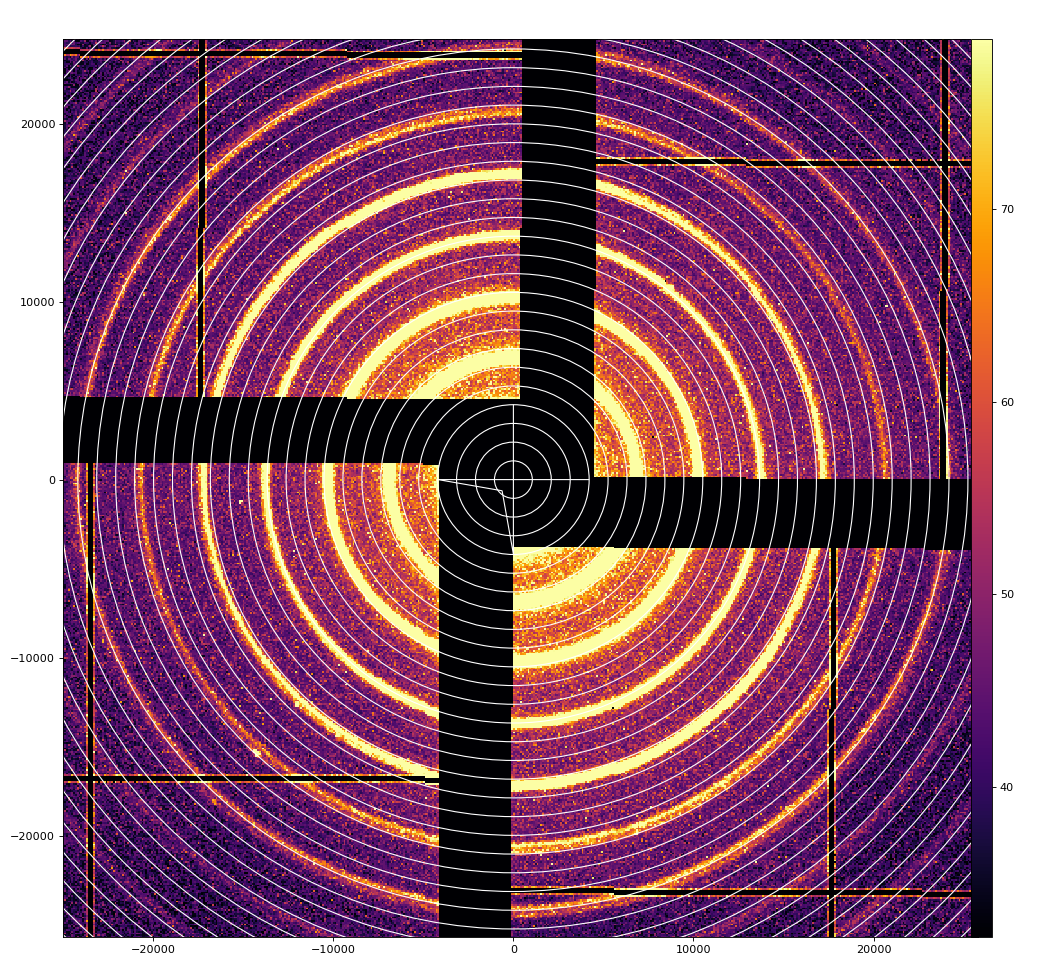

mfxc00318 run 10,13 lysozyme

psana direct and mirror image for crystfel

Geometry files centered for mfxc00318 run13 lysozyme

- 2020-02-25-geometry-epix10ka2m-v1.txt-mfxc00318-0013.txt

- 2020-02-25-geometry-epix10ka2m-v1.txt-mfxc00318-0013-mirror.txt

- 2020-02-25-geometry-epix10ka2m-v1.txt-mfxc00318-0013-mirror-crystfel.txt

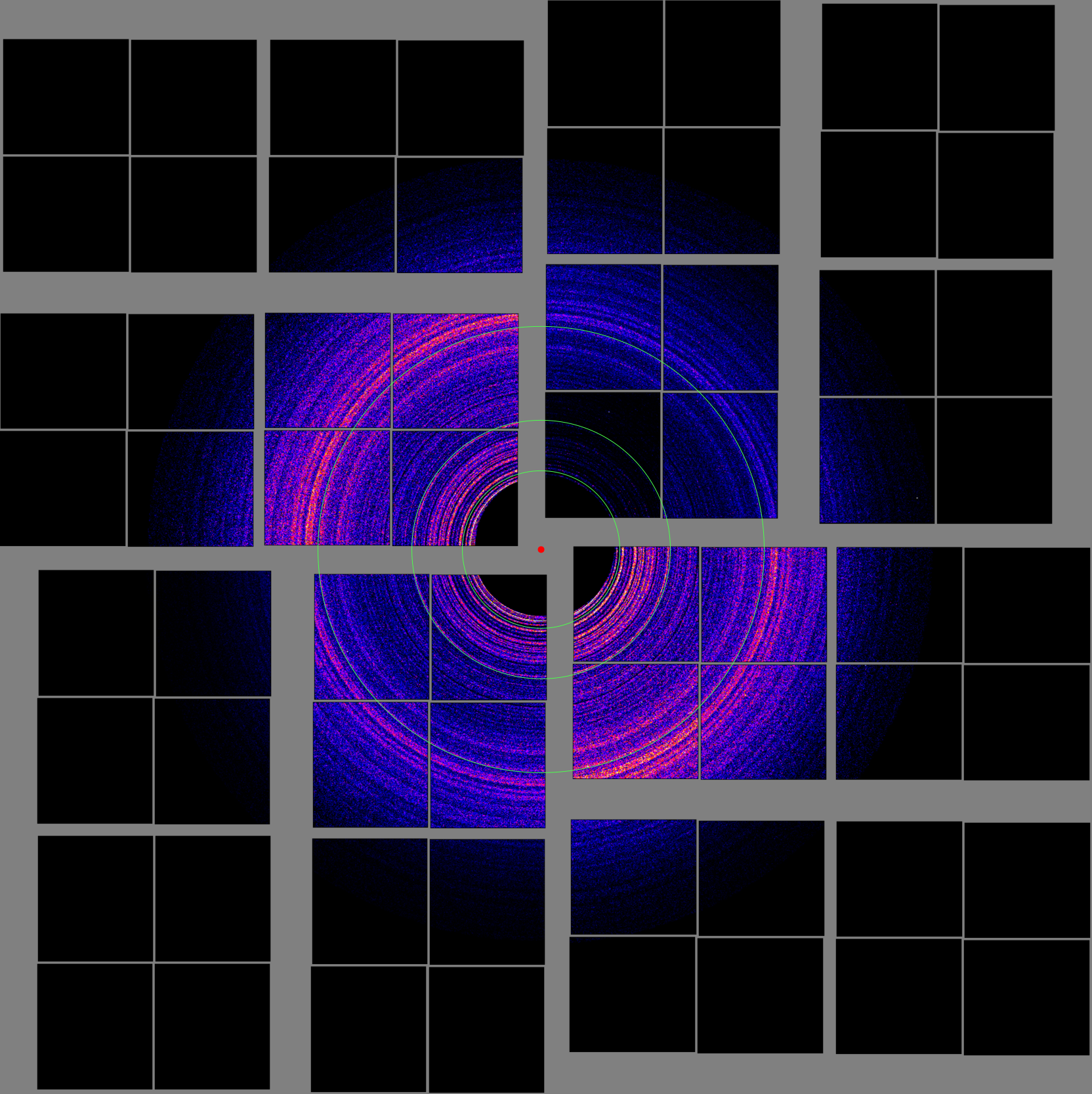

Geoptimizer or how geometry can be screwed-up if it is applied blindly

First thanks to Olexandr and Marina for discovering how our geometry should be mapped to data array.

However, as an intermediate step geoptimizer returned geometry which is significantly different from optical metrology, as shown in movie as comparing panels before (from opt metrology) and after optimization.

It is clear that blind application of geoptimizer may cause >1 mm offset of panels...

References

Overview

Content Tools