IP address: 134.79.218.154

Subnet Mask: 255.255.252.0

Default Gateway: 134.79.219.1

IP address change:

- Control panel

- View network status and tasks

- Click on ethernet connection

- Properties

- Internet Protocol Version 4(TCP/IPv4) → properties

- Change IP address to 134.79.218.--- (like 100)

- Subnet mask to 255.255.252.0

- No need for default gateway

What to do?

- Retrieve parameters

- save them on a file on the pc

- Address the questions of the SmartMotor on the controller

- Figure out how to connect the motors to the controller

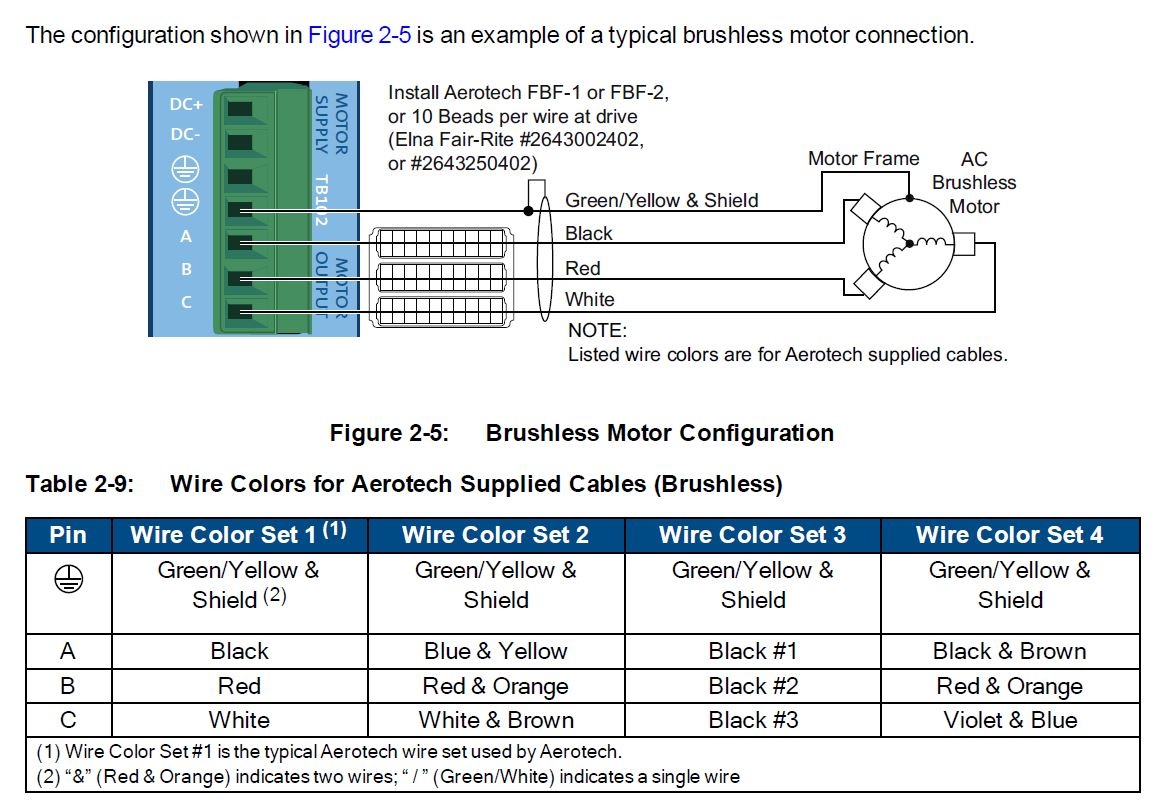

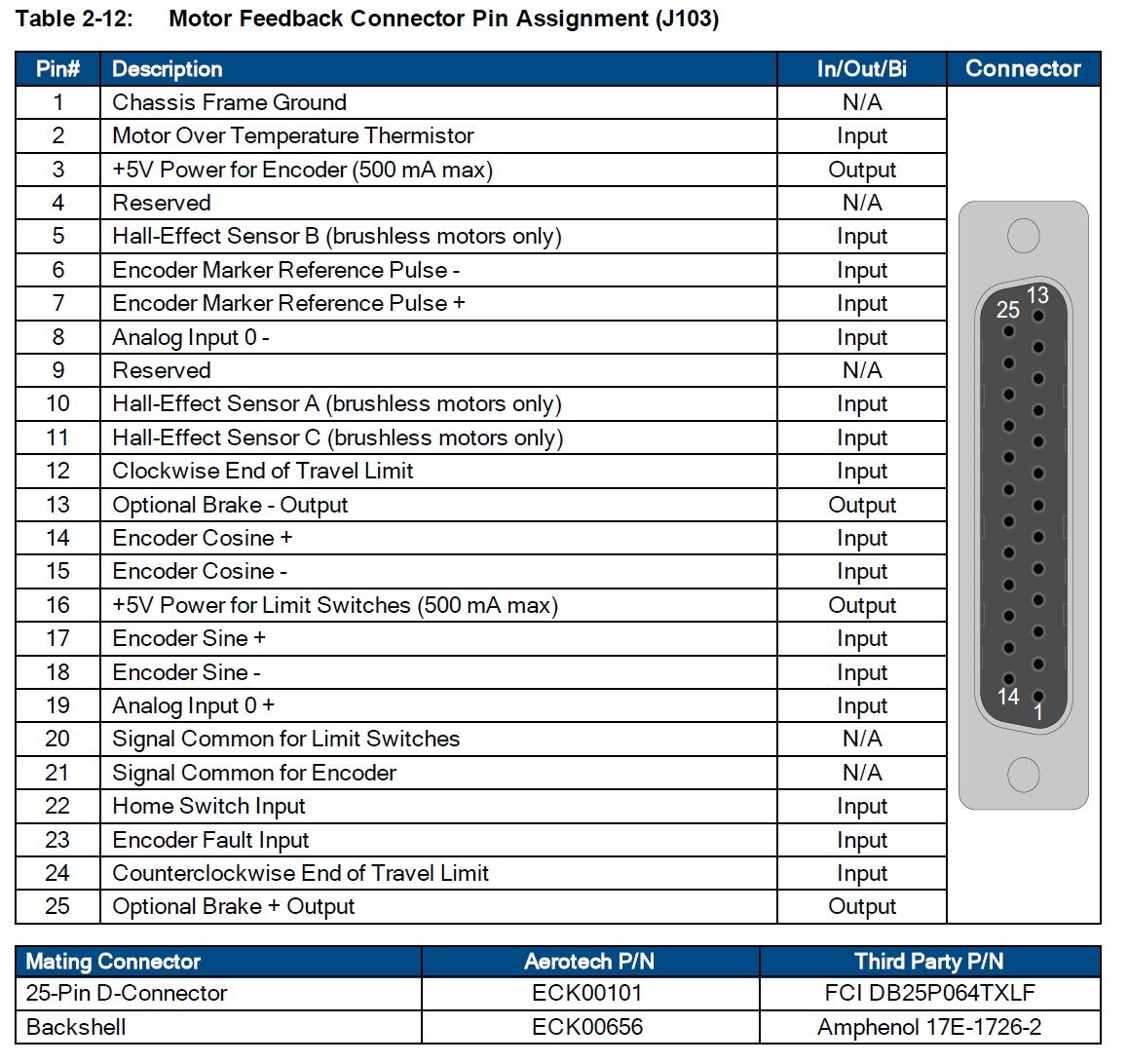

Aerotech BMS60-A-D25-FLB-E1000ASH-15DM (BRUSHLESS MOTOR):

fig 1: brushless motor connections

fig 2: feedback connections

fig 3: specs