...

Action when fail is to turn off the power of Peltier and module

Chiller

There are two ThermoCube units in B84/TID cabinet. Unit #1 is with full tubing setup and regularly used by Gabriel Blaj for LCLS so that we are trying to use unit #2 (no tubing) by assembling similar tubing arrangement as unit #1. Unit #2 has different coolant connectors compared to unit #1, but the rest of the tubing can work the same way still.

| Unit #2 Model | 10-400-3G20-1-CP2-R2-LT-AR |

|---|---|

| -400 | ~400W @ 20C with ambient air cooling for the Cube |

| 3G20 | >3 lpm @30 pig magnetic drive gear pump. Adjustable flow setting for 2 lpm. |

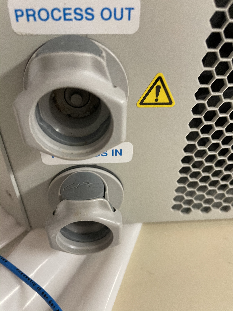

| CP2 | 3/8" CPC shut off valve (1-3 lpm) |

| R2 | RS232 interface controller |

| LT | Low temperature operation (<5C) |

| AR | Auto reset - software |

| Coolant connector (3/8" CPC) on unit #2 |

|---|

| Connection to the filter for unit #1 | Unit #1 with Swagelock QC4-316 joint for application insertion | |

|---|---|---|

|

Thermo Cube: Chiller manual

* CPC Quick disconnects are attached with chiller, need some coupling insert to connect to our tube (ID ~8mm/ OD ~11mm)

* options we have to are in this link (but seem no 1/4 in option)

Coolant

from Su Dong:

Tubing

- A) Application section (2*100cm): Our application tubing came with the CERN shipment is 8mm ID/11.5mm OD that fit well onto the cooling block thread nose. Need to terminate at two ends with Swagelock quick connect QC4-316. Is there a suitable part for the 8mm ID tubing ?

- B) Application joint to chiller Process In (30+15cm): Application joint is QC4-316 with 1/4" tube for ~30cm then transition to a short (15cm) 1/2" tube to fit onto the hose barb from the HFC 12 series (rating only down to 0C ?) which can connect with the 3/8" CPC at chiller Process In.

- C) Application joint to filter (or Process Out) (30+15cm): similar piece like B), such that the hose barb end can plug directly into the chiller Process Out, or filter out.

- D) Filter: Not yet identified the exact part for the filter. Also needs caution whether filter is compatible with <0C coolant. The filter output end should be fitted with the 3/8" NPT shutoff as those on the chiller unit. Filter inlet (fitting unknown) needs to transition to 1/2" tuber over the 3/8" hose barb to connect to the chiller Process Out.

- E) Jacket insulation: At least all thinner tubing section should have foam jacket insulation to allow running coolant <~0C.

Coolant

We intend to use the ThermoCube recommended coolant There may be some additional piping volume within chiller besides the 300ml tank. It may sufficiently safe if we get two 700ml bottles of the recommended coolant by ThermoCube: Koolance 702 (27% propylene glyco + water mix): https://koolance.com/liq-702-liquid-coolant-bottle-high-performance-700ml-blue. Propylene glyco is a nicer substance (used as food additive in some cases) than the more commonly used ethylene glyco as an alternative antifreeze.

The exact model of the ThermoCube we are working with is 10-400-3G20-1-CP2-R2-LT-AR which I think means: 400W capacity, >3 lpm @ 30 psig magnetic drive gear pump, with adustable flow setting for 2 lpm, 3/8" CPC shutoff valve, RS232 interface, low temp op (<5 deg C) and auto restart software.This might an old model which ThermoCube tank is 300 ml but there may be some additional piping volume within chiller besides the 300ml. The tubing outside the chiller (not including filter) is <~200ml. So it may sufficiently safe if we get two 700ml bottles of the recommended Koolance 702. This unit description doesn’t say what type of cold plate it ishas. Stainless would have carried a tag ’S” some where in the model number somewhere so this may be old style anodized AL PCW plate ? Koolance claims to be friendly with both Al and SS.

...