Outline

- Stave Loading Tooling, 19-1 RD53a L1 Stave – .zip - 11 March 2022.zip

- Stave Loading Tooling, 19-1 RD53a L0 Stave

- Ring Loading Tooling, 19-1 RD53a

- Handling Frame, 19-1 RD53a L1 Stave

- Shipping Box, 19-1 RD53a L1 Stave

Stave Loading Tooling, 19-1

...

L1 Stave

Version 2, revised, Stave Loading Tooling drawing drafts (not released):

...

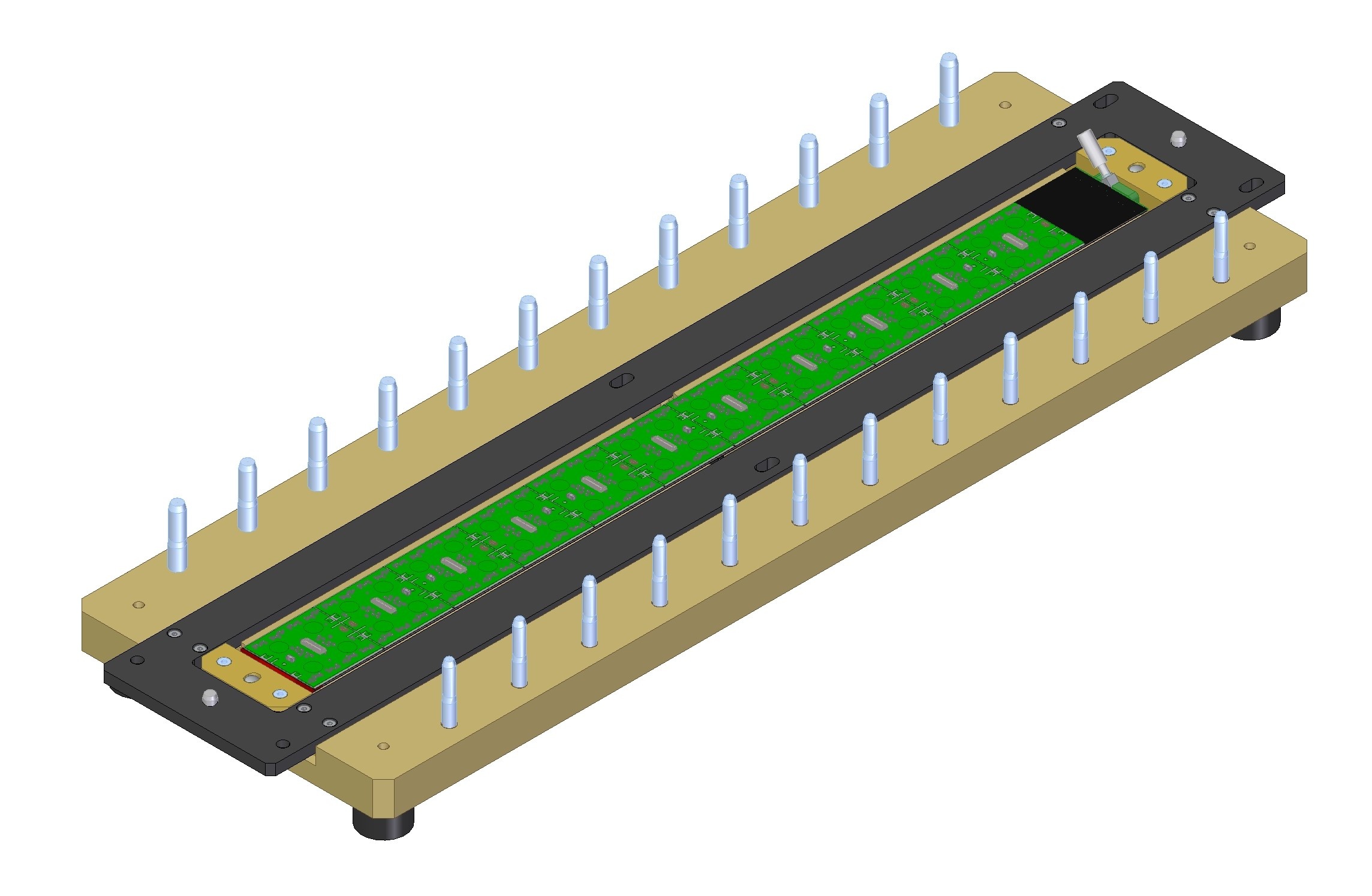

- Top Level Assembly: REF-000202041 (LOADING FIXTURE ASSY, 19-1 OB L1 STAVE).pdf

- Baseplate: REF-000203575 (BASEPLATE AND PINS, LOADING FIXTURE, OB L1 STAVE, 19-1, V2).pdf

- Loading Bridge: REF-000202287 (LOADING BRIDGE, FIXTURE, 19-1 OB L1 STAVE).pdf

- Covers for loaded modules: REF-000202337 (COVER SECTION, 19-1 OB L1 STAVE).pdf

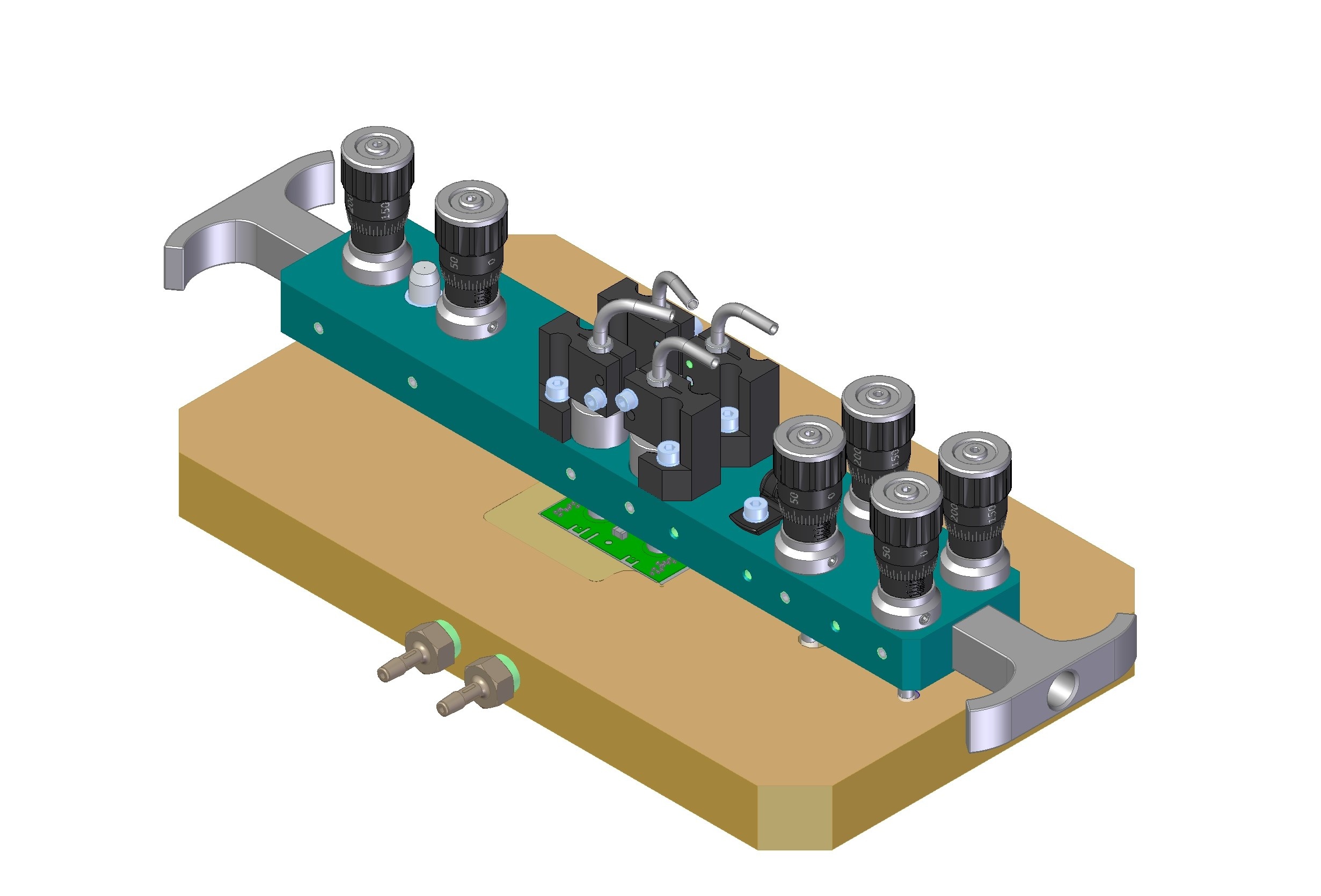

- Pickup table assy: REF-000202485 (PICK UP TABLE, QUAD, 19-1 OB L1 STAVE LOADING FIXTURE).pdf

- Handling Frame Assembly: REF-000203023 (HANDLING FRAME, OB L1 STAVE, 19-1).pdf

...

| Items | Vendor | Date | Response | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| GoProto | 3/3/2022 | Working on quote | ||||||||

| SLAC machine shop | 3/4/2022 | |||||||||

| KAL Machining | 3/7/2022 | No bid (capacity) |

| Parametric USA | 3/7/2022 | Quote: PQ104809.pdf $8k, 4-5 week lead |

| Pro-Tek Manufacturing | 3/7/2022 | Ordered 3/29/2022 |

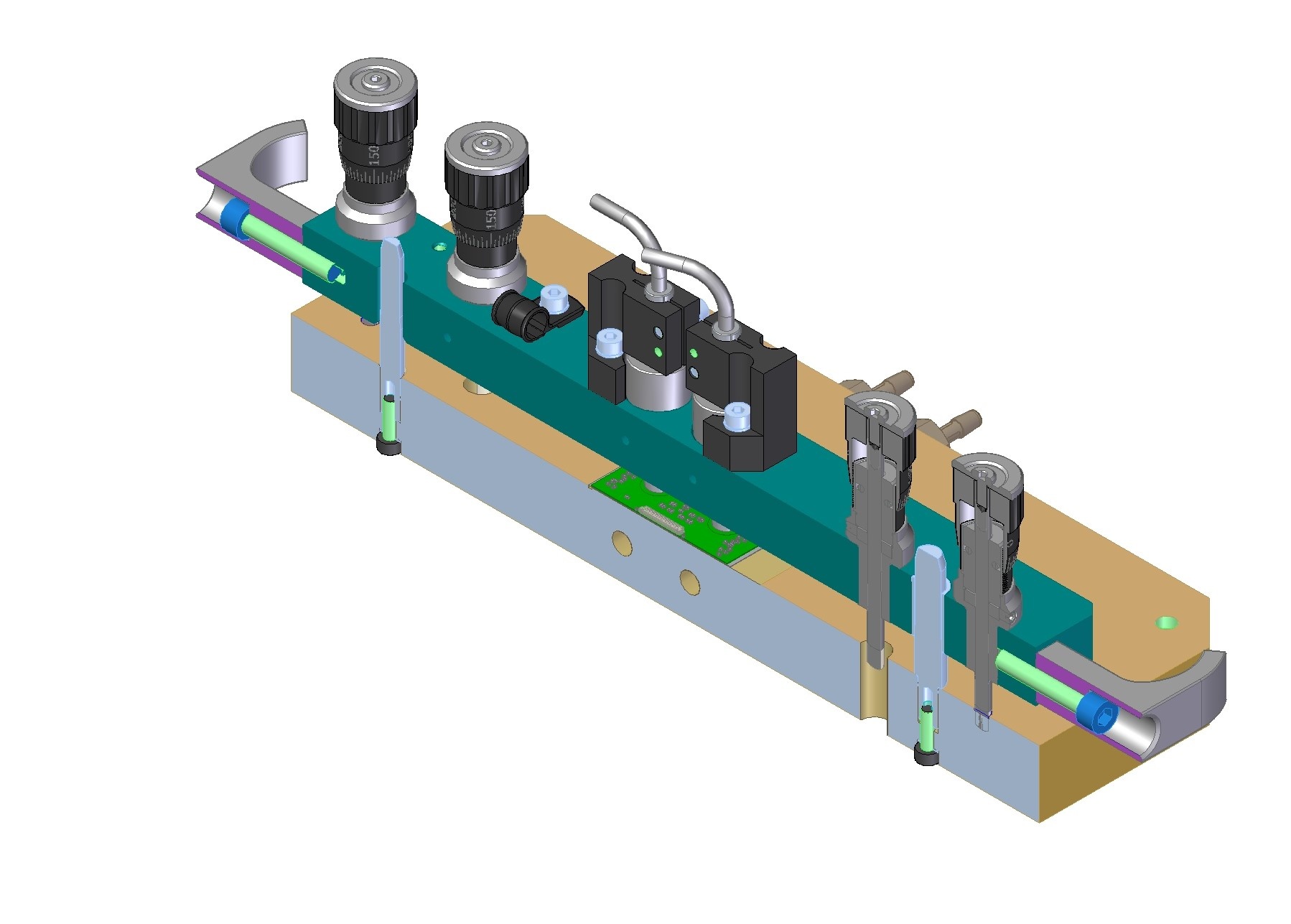

Loading Tooling, OB L1 Stave:

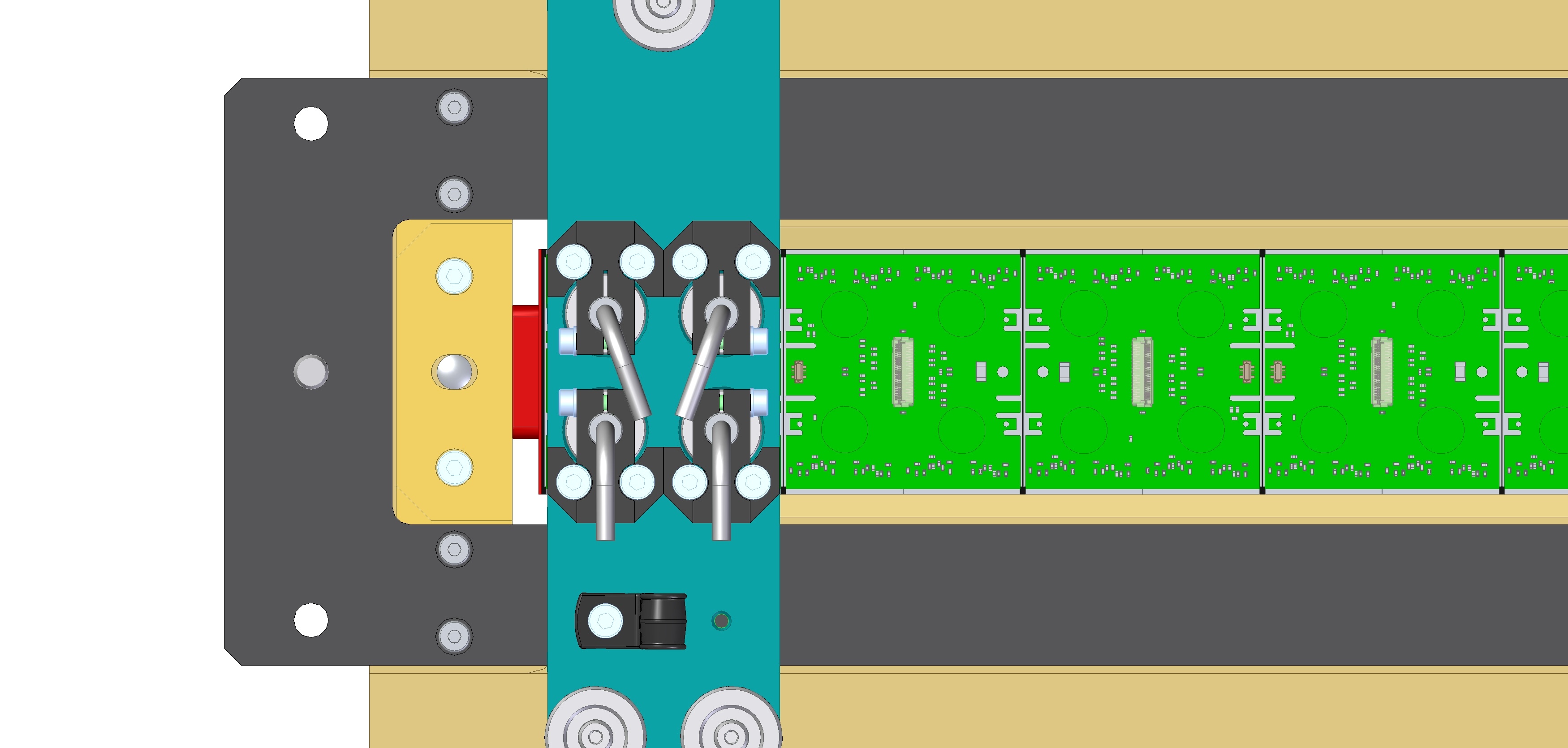

Section view:

Summary of requirements for loading 19-1 Outer Barrel Stave:

- Load RD53a Quad modules (drawings: 150um, 400um) with connectors oriented as shown in picture above

- Load modules onto 19-1 OB L1 Stave (no drawing yet, preliminary CAD on LBL Windchill site)

- Load without collisions: 200um nominal gap / 100 micron minimum gap between modules (no assembly drawing yet showing modules on stave)

- Glue layer thickness to be 100um -50/+100um

- ESD protection during loading: grounding of tooling

- Mechanical protection of wire bonds during loading: stay clear of wire bonds, handle modules using tooling only, consider covers/shields

- Baseplate to be installed onto glue robot: weight limit 7kg (per manual)

- Stave to be removed from baseplate and transferred to test box for QC testing

...

- Closely toleranced pins/bushings – same approach as used for 19-0 tooling

- Requirement: +/-75um module position tolerance in local support coordinate system (per requirements document "ITk Pixel Module Loading Accuracy Requirements" AT2-IP-ES-006-v3)

- Distribute tolerances:

- +/-50um module position relative to loading tooling baseplate coordinate system (to avoid collisions with 100um gap between modules).

- Dowel pins in baseplate – two per module location.

- Bridge to have bushing and slot for precision fit onto dowel pins.

- +/-25um local support position relative to loading tooling baseplate coordinate system (to accurately place modules to meet +/-75um requirement).

- Dowel pin in baseplate – to accurately locate one end of the Stave in Z.

- Tooling to fasten to mounting features on ends of Stave.

- +/-50um module position relative to loading tooling baseplate coordinate system (to avoid collisions with 100um gap between modules).

- Glue with beads to control glue layer thickness

- 100um dia beads, for ~75um glue layer thickness on carbon fiber.

- Loading tooling does NOT control the glue layer thickness.

- Loading bridge to rest on the module's pickup areas (vacuum pad locations) during gluing.

- Loading bridge to have micrometer adjusters to level the tool relative to the baseplate – to apply pressure at all vacuum pad locations during gluing.

- Loading bridge to have micrometer adjusters to level the tool relative to the pickup table – to make good contact between vacuum pads and module.

- Vacuum pads to pick up modules

- Vacuum pads to fit within clear areas on modules.

- Height adjustment of vacuum pads while on pickup table.

- Vacuum to securely hold modules.

- Tolerances:

- Module position relative to loading tooling baseplate (need +/-.050mm):

- Baseplate has:

- Dowel pin, stepped, 6mm OD, h7 tolerance. (Misumi SWPG6-P6-Q5.5-L12-B12-E3-F15)

- Dowel pin, stepped, 8mm OD, h7 tolerance. (Misumi HWPG6-P8-Q7.5-L11-B12-E3-F15)

- Loading bridge has:

- Bushing, 8mm ID, G6 tolerance. (Misumi JBAUN8-20)

- Machined slot, 6mm internal width, G6 tolerance.

- Baseplate has:

- Module position relative to loading tooling baseplate (need +/-.050mm):

Dimensioning scheme changed to hole-to-hole tolerancing (instead of hole-to-edge):

| Tolerance Item | Where Used | Tolerance (mm, Dia.) | ||

| Pick-up Table Edge Repeatability | Locating Module to Pickup Table (repeatability of lining up module to machined edges)Locating Module to | 0.025 | ||

| Pickup Table | .000 | Bridge Bushing ID | Locating Loading Bridge to Pick-up Table | 0.012019 |

| Bridge Pick-up Table Pin OD | Locating Loading Bridge to Pick-up Table | 0.012 | ||

| Pin Location | Locating Loading Bridge to Pick-up Table | .025 | ||

| 015 | ||||

| Baseplate Hole Bridge Bushing ID | Locating Loading Bridge to Loading Fixture | 0.012025 | ||

| Baseplate Bridge Pin OD | Locating Loading Bridge to Loading Fixture | 0.012015 | ||

| Pin Baseplate Hole Location | Locating Loading Bridge to Loading Fixture (hole locations dimensioned as +/-.04 from adjacent hole, i.e. up to -.02 per hole) | 0.025020 | ||

Total: | .098mm 119mm (+/-.050mm060mm) | |||

| Root Sum Square: | .043mm 050mm (+/-.019mm025mm) |

Stave position relative to loading tooling baseplate

...

:

| Tolerance Item | Where Used | Tolerance (mm, Dia.) |

| Pin Location | Locating Stave to BaseplateLoading Bridge to Loading Fixture (hole locations dimensioned as +/-.04 from adjacent hole, i.e. up to -.02 per hole) | 0.020.025 |

Pick-up Table Edge Accuracy (absolute position) | Locating Module to Pick-up Table *this item affects all modules equally so does not affect gap/distance between modules | 0.025060 |

| Total: | 0.080mm (+/-.040mm) | |

| Root Sum Square: | 0.063mm .050mm (+/-.025mm032mm) |

- Total for all:

- Limit: +/-.074mm100mm

- Root sum square: +/-.028mm040mm

- Requirement: +/-.150mm

- Module Nominal Spacing (for 19-1 L1 Stave): .250mm (nominal gap)

- Worst case clearance: 0.012mm

- Clearance with RSS tolerance (3σ): 0.180mm

A design/drawings were made in 2020 (Version 1, deprecated, not released):

...

Stave Loading Tooling, 19-1 IB Stave

Requirements - see OB L1 Stave requirements above.

...

Design concept: modify design of 19-1 OB L1 Stave tooling to match Triplet dimensions and pickup areas

...

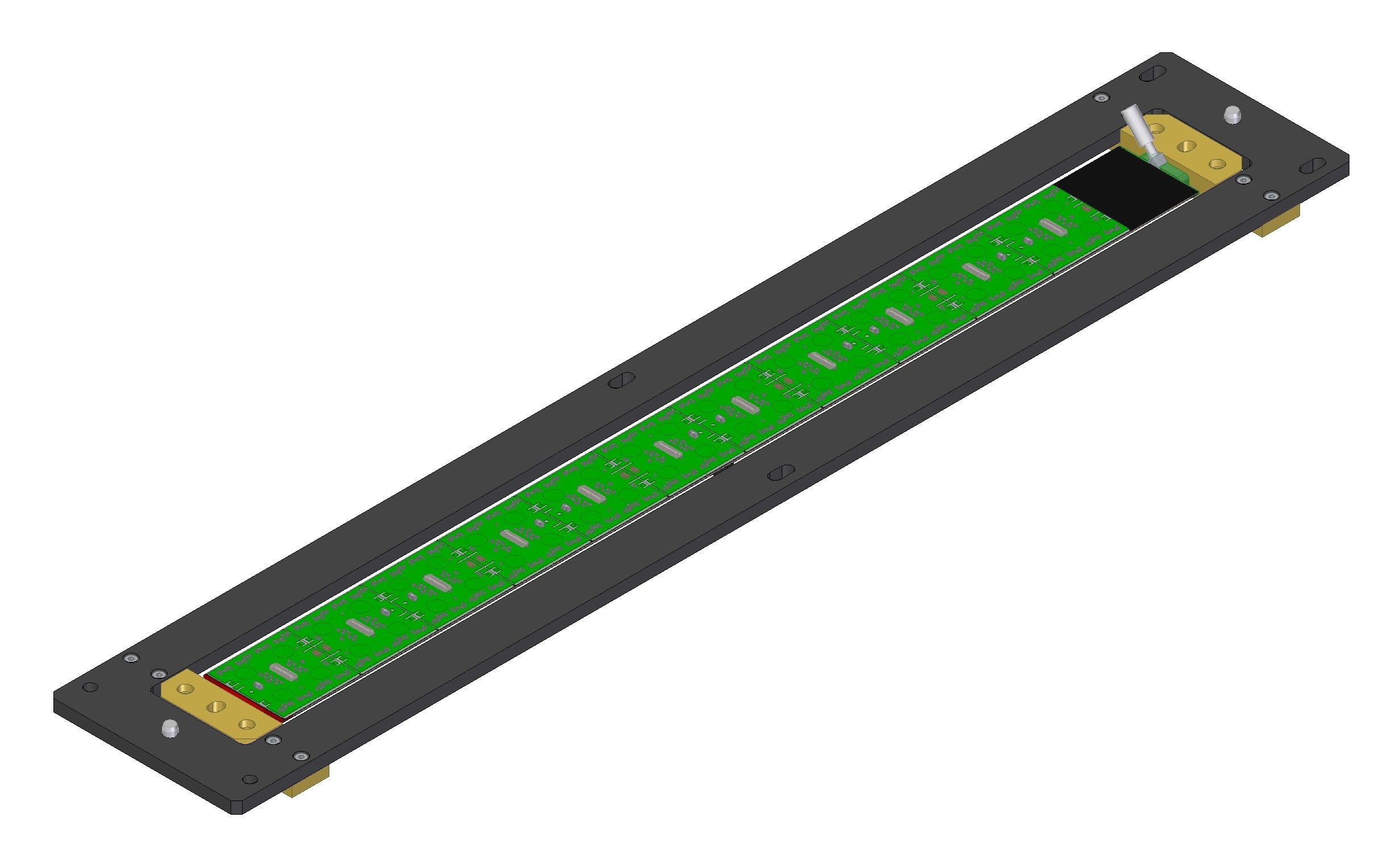

Drawings (not released): REF-000202479 (SHIPPING AND STORAGE FIXTURE, OB L1 STAVE, 19-1) CHECKPRINT 14FEB2022.zip

Handling Frame with 19-1 OB L1 Stave:

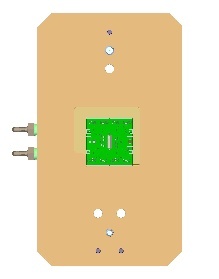

Interface block to join Stave and Handling Frame (drawing not released):

...