...

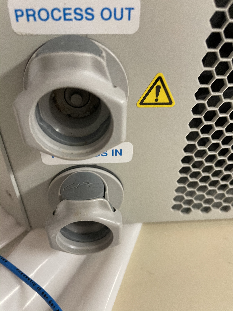

There are two ThermoCube units in B84/TID cabinet. Unit #1 is with full tubing setup and regularly used by Gabriel Blaj for LCLS so that we are trying to use unit #2 (no tubing) by assembling similar tubing arrangement as unit #1. Unit #2 has different coolant connectors compared to unit #1, but the rest of the tubing can work the same way still.

| Unit #2 Model | 10-400-3G20-1-CP2-R2-LT-AR |

|---|---|

| -400 | ~400W @ 20C with ambient air cooling for the Cube |

| 3G20 | >3 lpm @30 pig magnetic drive gear pump. Adjustable flow setting for 2 lpm. |

| CP2 | 3/8" CPC shut off valve (1-3 lpm) |

| R2 | RS232 interface controller |

| LT | Low temperature operation (<5C) |

| AR | Auto reset - software |

| Coolant connector (3/8" CPC) on unit #2 | Connection to the filter for unit #1 | Unit #1 with Swagelock QC4-316 joint for application insertion |

|---|---|---|

|

...

- A) Application section (2*100cm): Our application tubing came with the CERN shipment is 8mm ID/11.5mm OD that fit well onto the cooling block thread nose. Need to terminate at two ends with Swagelock quick connect QC4-316. Is there a suitable part for the 8mm ID tubing (SS-QC4-DC-8M0) ?

- B) Application joint to chiller Process In (30+15cm): Application joint is QC4-316 with 1/4" tube (SS-QC4-D-400 / SS-QC4-B-400) for ~30cm then transition to a short (15cm) 1/2" tube to fit onto the hose barb from the HFC 12 series (rating only down to 0C ?) which can connect with the 3/8" CPC at chiller Process In.

- C) Application joint to filter (or Process Out) (30+15cm): similar piece like B), such that the hose barb end can plug directly into the chiller Process Out, or filter out.

- D) Filter: Not yet identified the exact part for the filter. Also needs caution whether filter is compatible with <0C coolant. The filter output end should be fitted with the 3/8" NPT shutoff as those on the chiller unit. Filter inlet (fitting unknown) needs to transition to 1/2" tuber over the 3/8" hose barb to connect to the chiller Process Out.

- E) Jacket insulation: At least all thinner tubing section should have foam jacket insulation to allow running coolant <~0C.

...