Page History

| Table of Contents |

|---|

Why do I think that 2020-02-25 optical metrology is good

- very good quality check

- all z-measurements are around 1 feet, have a lit of repeatable numbers - can't be trusted

...

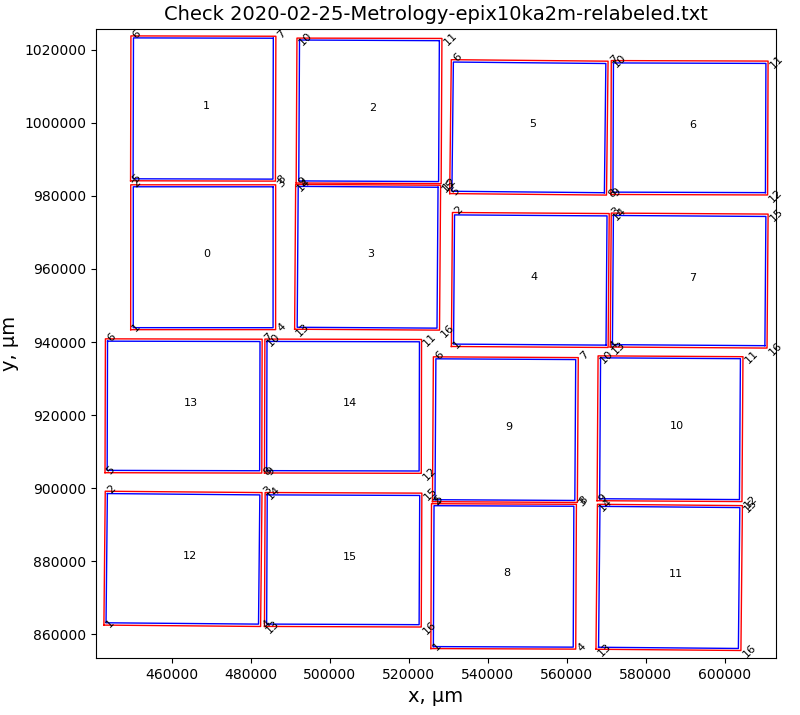

- red rectangles - for points measured in optical metrology

- blue rectangles - panels reconstructed from geometry file

DAQ panel indexes in optical metrology possible detector orientations

| Code Block | ||

|---|---|---|

| ||

rot = 0 ^y

Q0 1 3 | 4 5 Q1

0 2 | 6 7

---------+----------> x

15 14 | 10 8

Q3 13 12 | 11 9 Q2

rot = 1 ^y

Q3 13 15 | 0 1 Q0

12 14 | 2 3

---------+----------> x

11 10 | 6 4

Q2 9 8 | 7 5 Q1

rot = 2 ^y

Q2 9 11 | 12 13 Q3

8 10 | 14 15

---------+----------> x

7 6 | 2 0

Q1 5 4 | 3 1 Q0

rot = 3 ^y

Q1 5 7 | 8 9 Q2

4 6 | 10 11

---------+----------> x

3 2 | 14 12

Q0 1 0 | 15 13 Q3

|

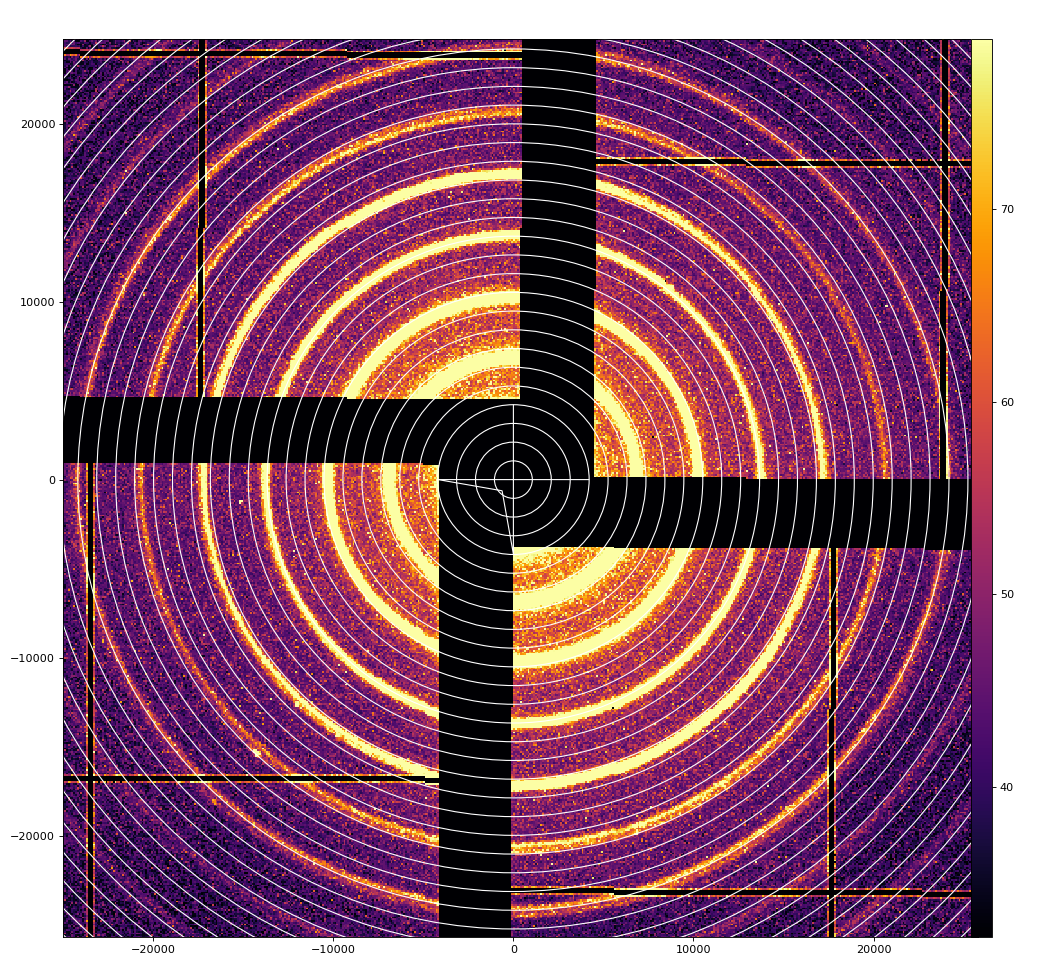

Images of panels in data for all detector orientations in metrology processing v1 without quads

- v1 of the metrology processing script represents simplest approach - each panel coordinates are taken as is to insert in the detector

- data from mfxc00118 run44 silver-behenate sample

...

- numeration of quads at rotation looks symmetric - so seems right

- one orientation of the detector gives correct image and it shows smallest offsets between panels in quads

mfxc00118 run44 silver-behenate

mfxc00318 run 10,13 lysozyme

psana direct and mirror image for crystfel

Geometry files centered for mfxc00318 run13 lysozyme

- 2020-02-25-geometry-epix10ka2m-v1.txt-mfxc00318-0013.txt

- 2020-02-25-geometry-epix10ka2m-v1.txt-mfxc00318-0013-mirror.txt

- 2020-02-25-geometry-epix10ka2m-v1.txt-mfxc00318-0013-mirror-crystfel.txt

Geoptimizer or how geometry can be screwed-up if it is applied blindly

First, thanks to Olexandr and Marina for discovering how our geometry should be mapped to data array.for discovering how our geometry should be mapped to data array.

| Code Block | ||||

|---|---|---|---|---|

| ||||

Yefanov, Oleksandr <oleksandr.yefanov@cfel.de> Tue 8/18/2020 1:18 PM

To: Dubrovin, Mikhail; O'Grady, Paul Christopher

Cc: Hart, Philip Adam; Chun Hong Yoon <chuckyoon@stanford.edu>; Batyuk, Alex; Mariani, Valerio; McKelvey, Mark E

2 attachments (5 MB)Download allSave all to OneDrive - SLAC National Accelerator Laboratory

Hi Michail and others,

We’ve found the problem!!!!!

Hi Michail and others,

We’ve found the problem!!!!!

Sorry to say, but it’s from your side. :)

Solution at the end of the e-mail as a bonus for those who read the whole e-mail. :)

Actually I’ve written the e-mail while searching for the answer. But the text might be useful for those who work with geometries.

I believe that the optical metrology is right – I was wrong once, by thinking that CS-PAD metrology was not good and I don’t want to repeat my mistake. :)

But as with CS-PAD I’m afraid the problem is with attributing the optical metrology to the measured data. (here I’m right – see below :)

Unfortunately your arguments about influence of z-offset or out-of-plane tilts can be discarded using simple math.

For example at the attached image (…current.png) the middle green ring has radius of 200px = 20mm and the detector is approx. at 120mm. So to have in-plane offset of 2 pixels you’d need to shift a panel by 2mm. That’s too much. Also, as you can see, at left-bottom panel the rings overlap at the top side, but have distance at the left side of the panel. So to correct it you’d need out-of-plane rotation. 2 pixels (at 200px distance) would correspond to 11.5 degrees. Not realistic. :( And in the attached example error is 4-5 pixels!!! I’m not even mentioning that in case of the tilts and z-offset the behavior is different at different parts of the panel. You can see the effect of these distortions from geoptimizer’s error map.

The interesting observation is that I really see z-offset for panels and it is quite big (up to 1mm for corner panel). Fortunately in my algorithm z-offset cannot be confused with x-y (different parameter is considered), but as I mentioned, due to the geometry of the detector z-offset is much more sensitive to noise/error (for example wrong peaks). Therefore to find reliable z-offset of different panels I need more data. I’ve made a very good geometry for AGIPD (with z-offset up to 1mm) using ONLY measured data (optical metrology doesn’t exist for AGIPD), so it is actually possible. I’ll try to optimize z later when I have access to more data.

Now SOLUTION !!!

My student Marina tried to “rotate” the geometry – shifting the ss coordinate by 1408, 2816 and 4224 (1,2,3 quadrants). Apparently shift by 4224 gives correct geometry!!! Have a look at the attached shift4224.png. I’ve also indexed the data and checked with geoptimizer – it looks right (except z-offsets).

So please modify in this way your script that makes the geometry from metrology. Don’t forget to rotate the geometry to have visually correct detector – it doesn’t matter for SFX, but nice for users.

Please share the resulting geometry – I’d like to use it.

And I’ll try to add z-offsets to your resulting geometry when I have more data.

And Mikhail, I really want to thank you very much for good optical metrologies! It really saves users a lot of time!

Regards,

Oleksandr. |

However, before solution was found, However, as an intermediate step geoptimizer returned geometry which is significantly different from optical metrology, as shown in movie as comparing panels before (from opt metrology) and after optimization.

...

It is clear that blind application of geoptimizer may cause >1 mm offset of panels in x-y ...

References

...

Overview

Content Tools