This note is about application (script) which allows to check quality of the optical metrology input during measurement.

Content

Introduction

Optical metrology measurements contains enough information for self check. Historically this quality check is done offline when entire detector or its quad is measured and entire file is available. Sometimes this file contains typo, which can be fixed using over-defined rectangular geometry of the detector segments. However, it could be much better to fix this problem during optical measurements with microscope. Simple application which can check partial optical metrology input is now available and described in this note.

Get application up and running

Direct usage

Optical metrology quality check (QC) application is implemented as a self consistent script which uses standard python features with numpy and matplotlib libraries. It can be downloaded from

https://github.com/lcls-psana/CalibManager/blob/master/app/optical_metrology_check

and used as is by the command

python optical_metrology_check <opt-met-file.txt>

Use from psana release

For development purpose it could be better to use it through psana-conda release system. Code is available since ana-1.2.8. Example:

optical_metrology_check -h optical_metrology_check <opt-met-file.txt>

Example

A few complete optical metrology files can be found under directory /reg/g/psdm/detector/alignment/cspad/, e.g. calib-xpp-2016-08-22-camera3/2016-08-22-CSPAD-XPP-Camera3-Metrology.txt

However, script can run on partial metrology file, e.d.: metrology_test.txt, which can be downloaded and used for test purpose:

optical_metrology_check metrology_test.txt

Output

Running script prints a few section of results, e.g.:

X-Y quality check for optical metrology measurements ---------------------------------------------------------------------------------------------------------------------------- segm: S1 S2 dS1 dS2 L1 L2 dL1 dL2 angle(deg) D1 D2 dD d(dS) d(dL) ---------------------------------------------------------------------------------------------------------------------------- segm: 0 20903 20907 23 27 43542 43544 -15 -13 0.03290 48302 48304 -1 -4 -2 segm: 1 20911 20908 -81 -84 43545 43544 42 41 0.10855 48307 48302 4 3 1 segm: 2 20919 20907 117 105 43546 43540 -56 -62 -0.14606 48301 48310 -8 12 6 segm: 3 20910 20907 2 -1 43546 43550 -2 2 0.00066 48309 48308 1 3 -4 segm: 4 20909 20924 -99 -84 43546 43543 44 41 0.12040 48307 48309 -1 -15 3 ----------------------------------------------------------------------------------------------------------------------------

Z quality check for optical metrology measurements ----------------------------------------------------------------------------------------------------------------------------------------- segm: SA LA XSize YSize dZS1 dZS2 dZL1 dZL2 dZSA dZLA ddZS ddZL dZX dZY angXZ(deg) angYZ(deg) dz3(um) ----------------------------------------------------------------------------------------------------------------------------------------- segm: 0 20905 43543 43543 20905 -93 -125 -400 -432 -109 -416 32 32 -416 -109 -0.54737 -0.29874 -31.962 segm: 1 20909 43544 20909 43544 -165 -165 -187 -187 -165 -187 0 0 -165 -187 -0.45212 -0.24605 0.028 segm: 2 20913 43543 20913 43543 -248 -183 -225 -160 -215 -192 -65 -65 -215 -192 -0.59039 -0.25330 -64.821 segm: 3 20908 43548 43548 20908 -67 -70 -392 -395 -68 -393 3 3 -393 -68 -0.51771 -0.18771 -2.973 segm: 4 20916 43544 20916 43544 -175 -179 -155 -159 -177 -157 4 4 -177 -157 -0.48484 -0.20658 3.885 -----------------------------------------------------------------------------------------------------------------------------------------

Parameters to check

See for detail CSPAD Geometry and Alignment

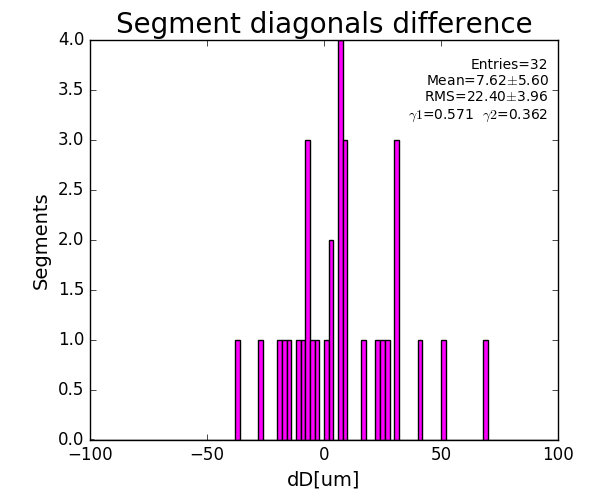

dD (um) - difference between diagonals

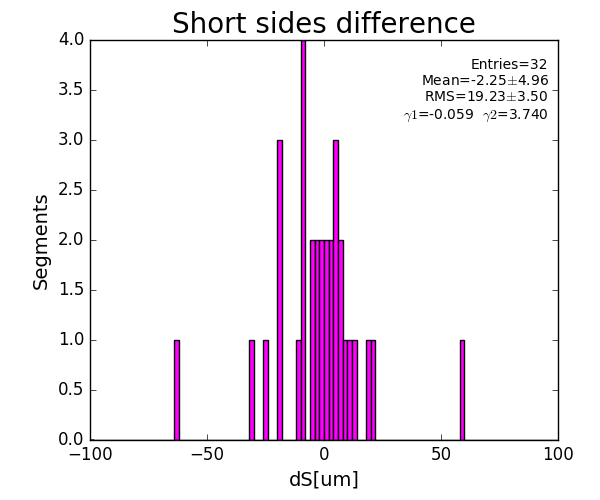

d(dS) (um) - difference between two short sides

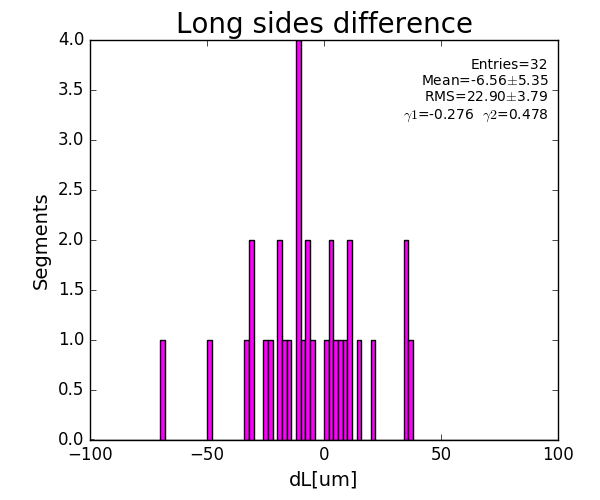

d(dL) (um) - difference between two long sides

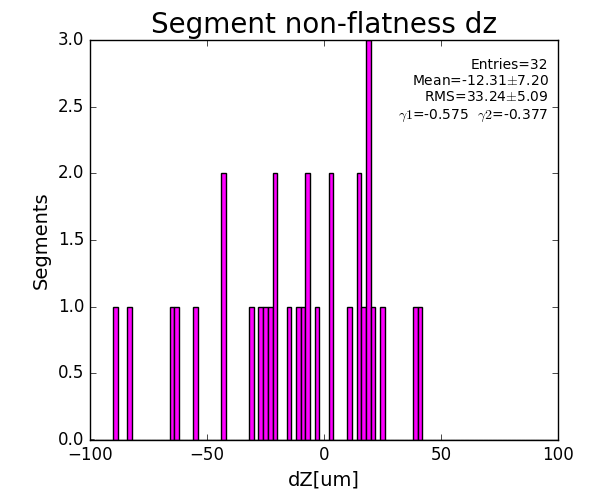

dz3 (um) - deviation one of the measured points from the plane of three other points

All these parameters should be about zero within fraction of the pixel size. If not... re-measurement is desirable.

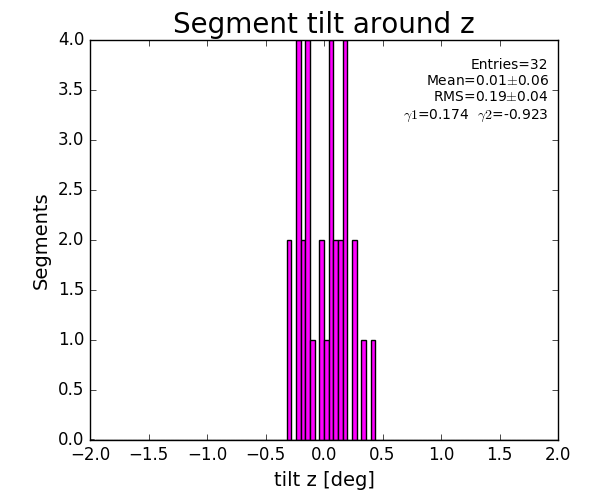

Plots

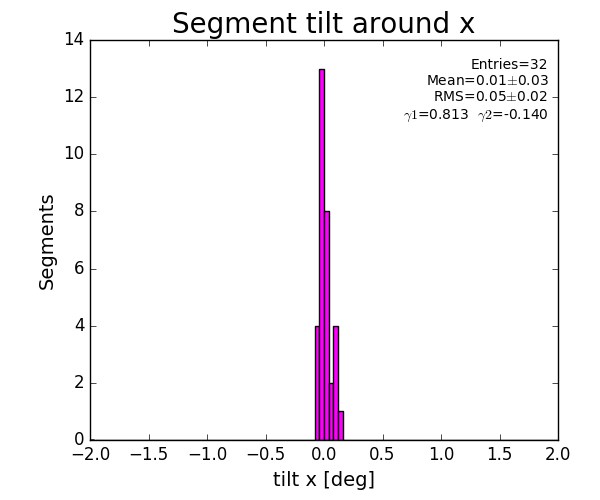

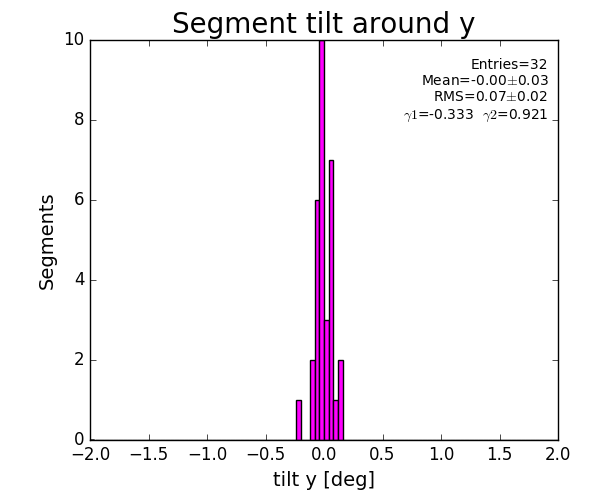

Application generates and saves in current directory a few useful plots;

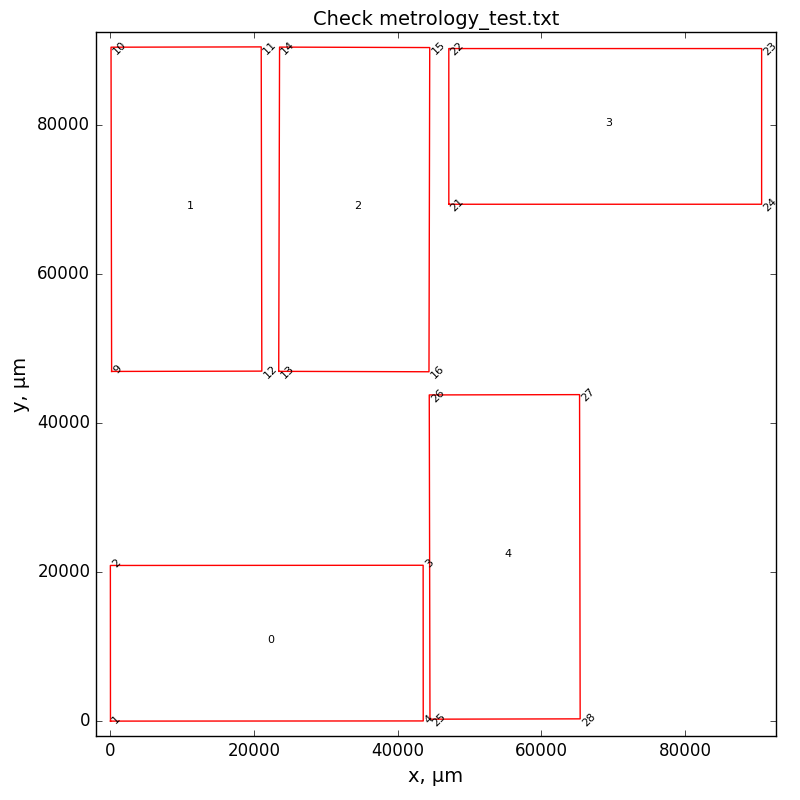

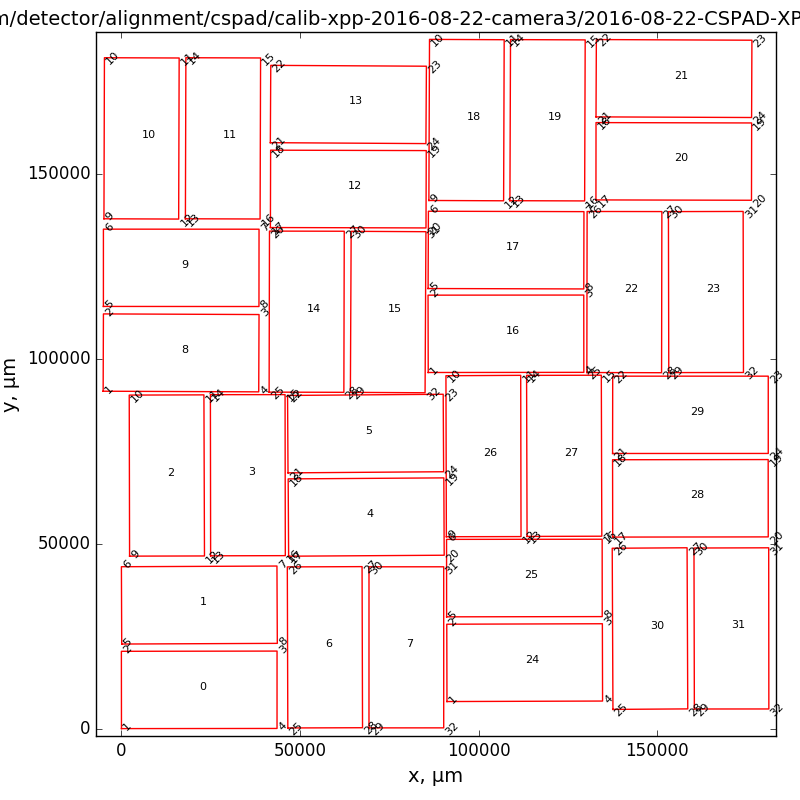

map of measured sensors for metrology_test.txt and 2016-08-22-CSPAD-XPP-Camera3-Metrology.txt metrology files:

frequency distributions of a few important parameters, as shown for 2016-08-22-CSPAD-XPP-Camera3-Metrology.txt

References