Table of Conents

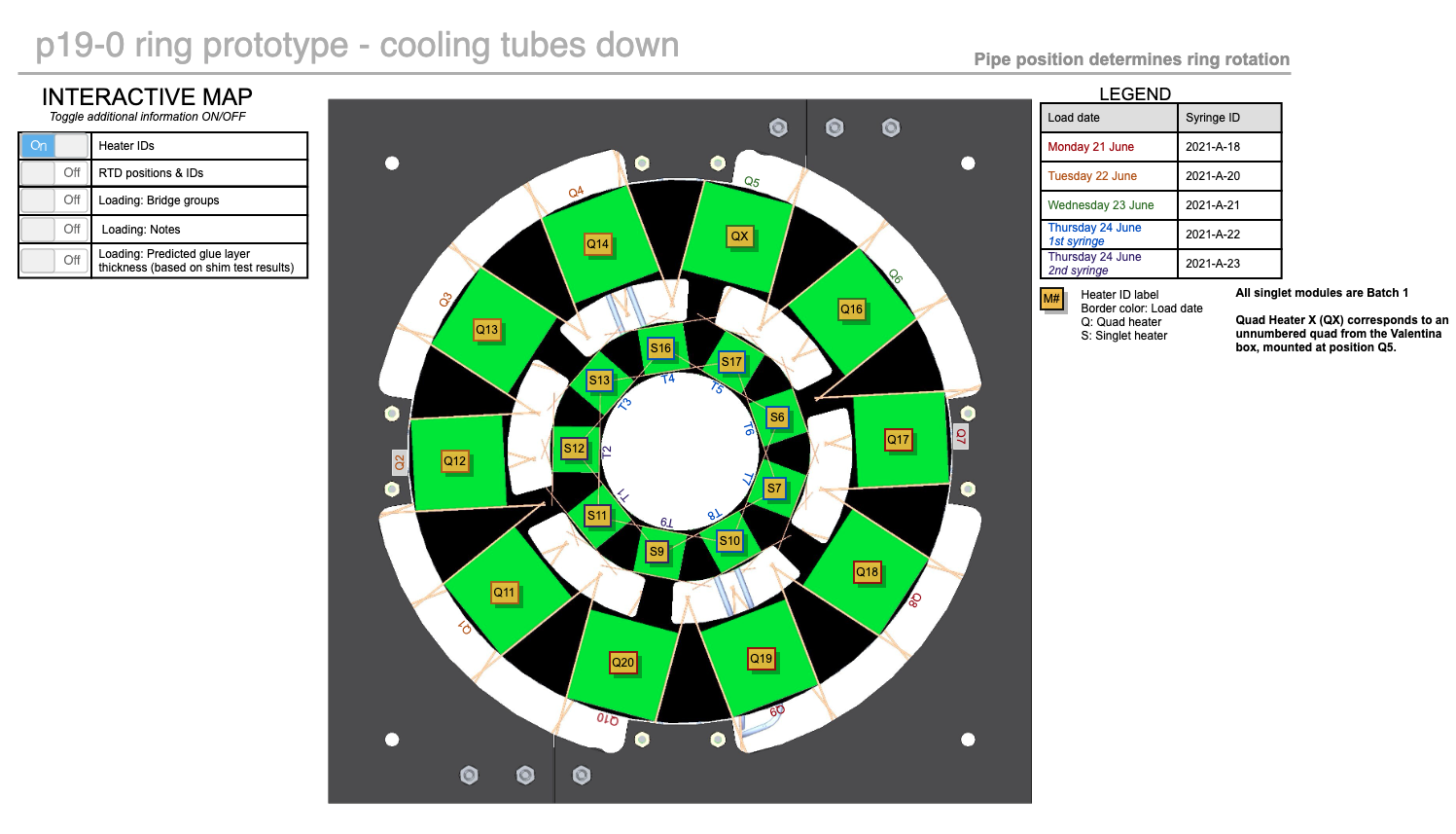

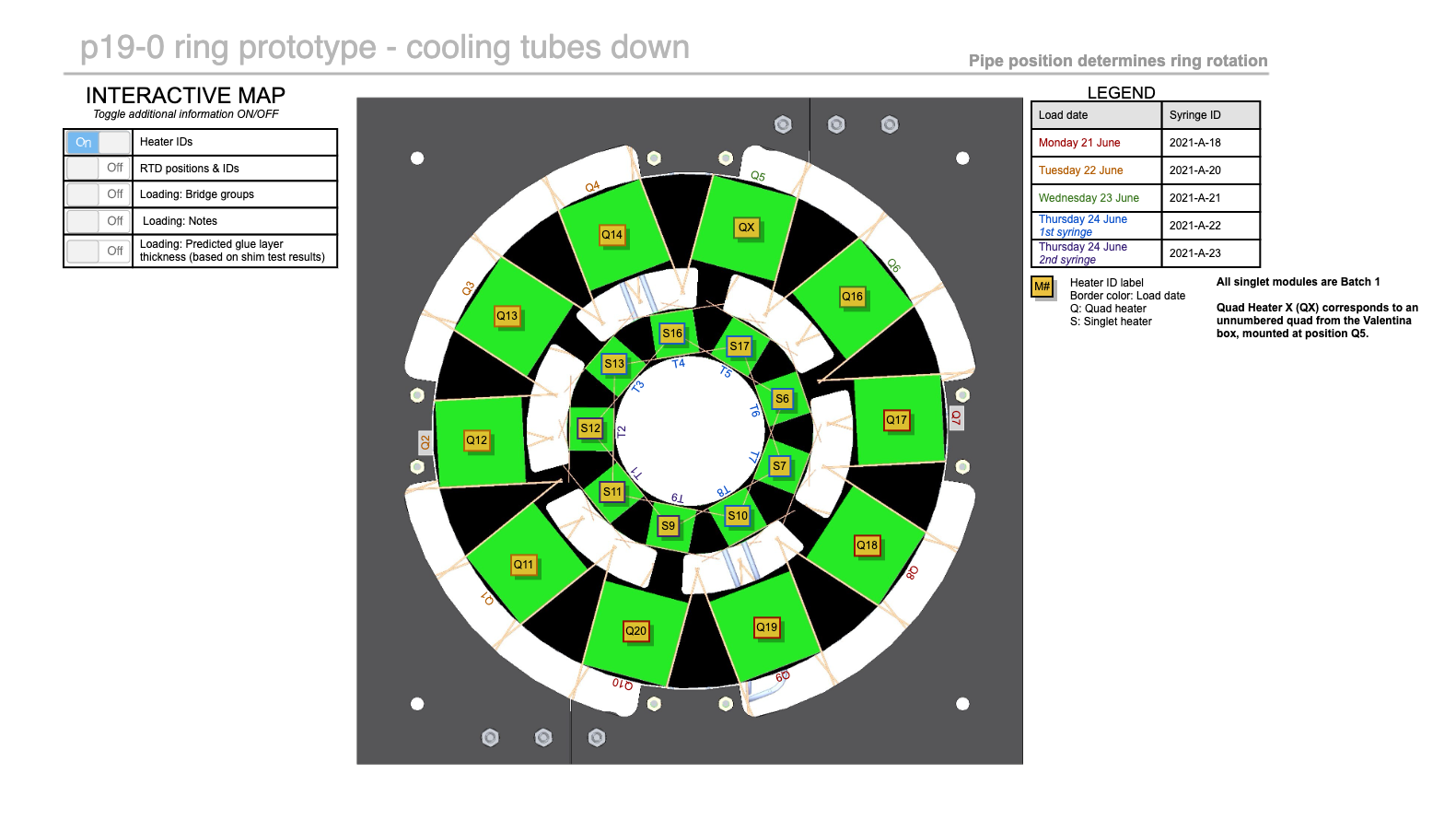

p19-0 ring tubes down interactive map

Welcome to the interactive map of the first thermomechanical ring prototype at SLAC. You can visit the Cooling Tubes Up map here.

To explore the ring map in interactive mode, use the buttons within the Gliffy diagram macro in the table on the left. You may need to enter full screen. Hover your mouse over the image to get the full screen menu option. Please note that this interactive map only includes loading information. Please visit the Metrology section for the Metrology results.

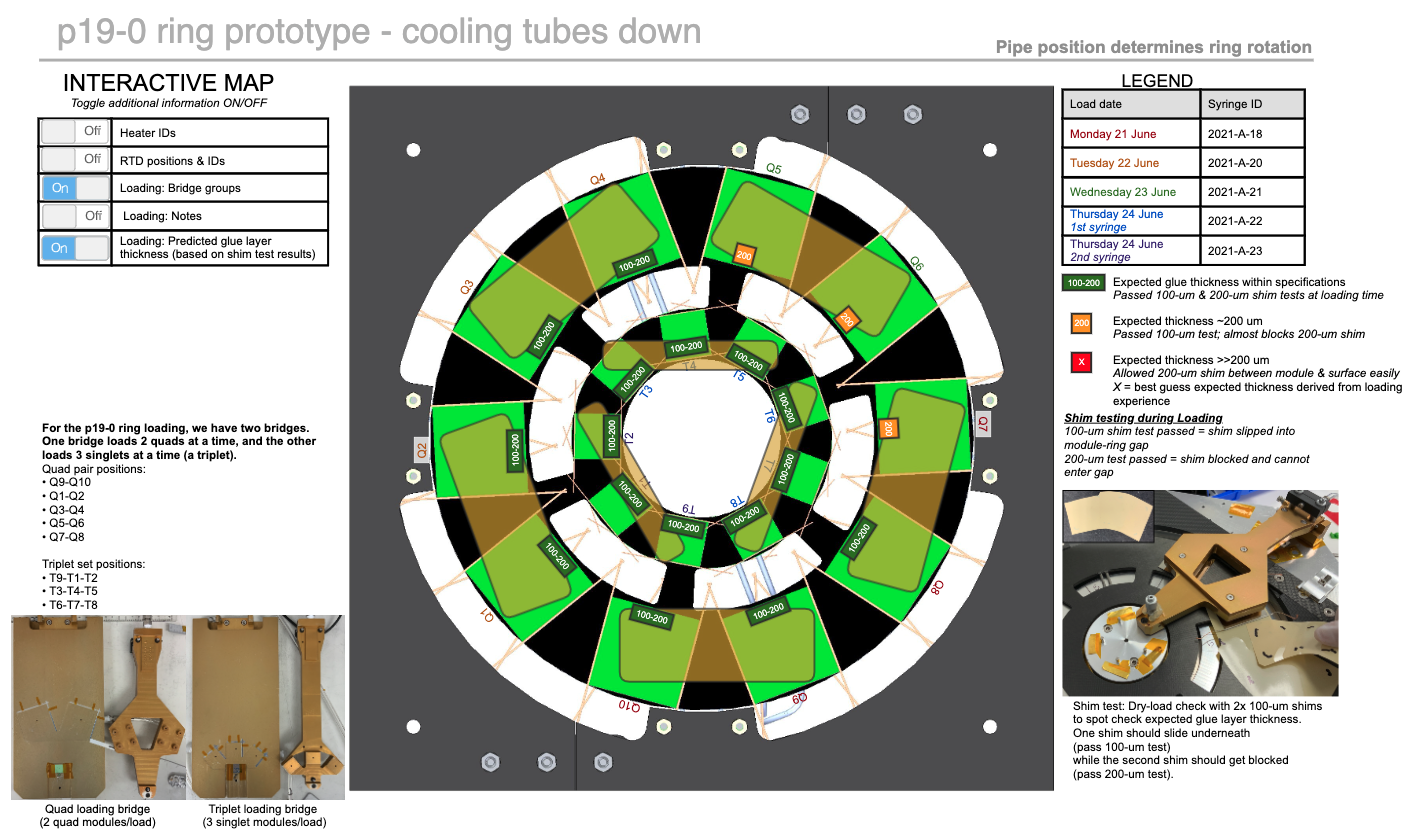

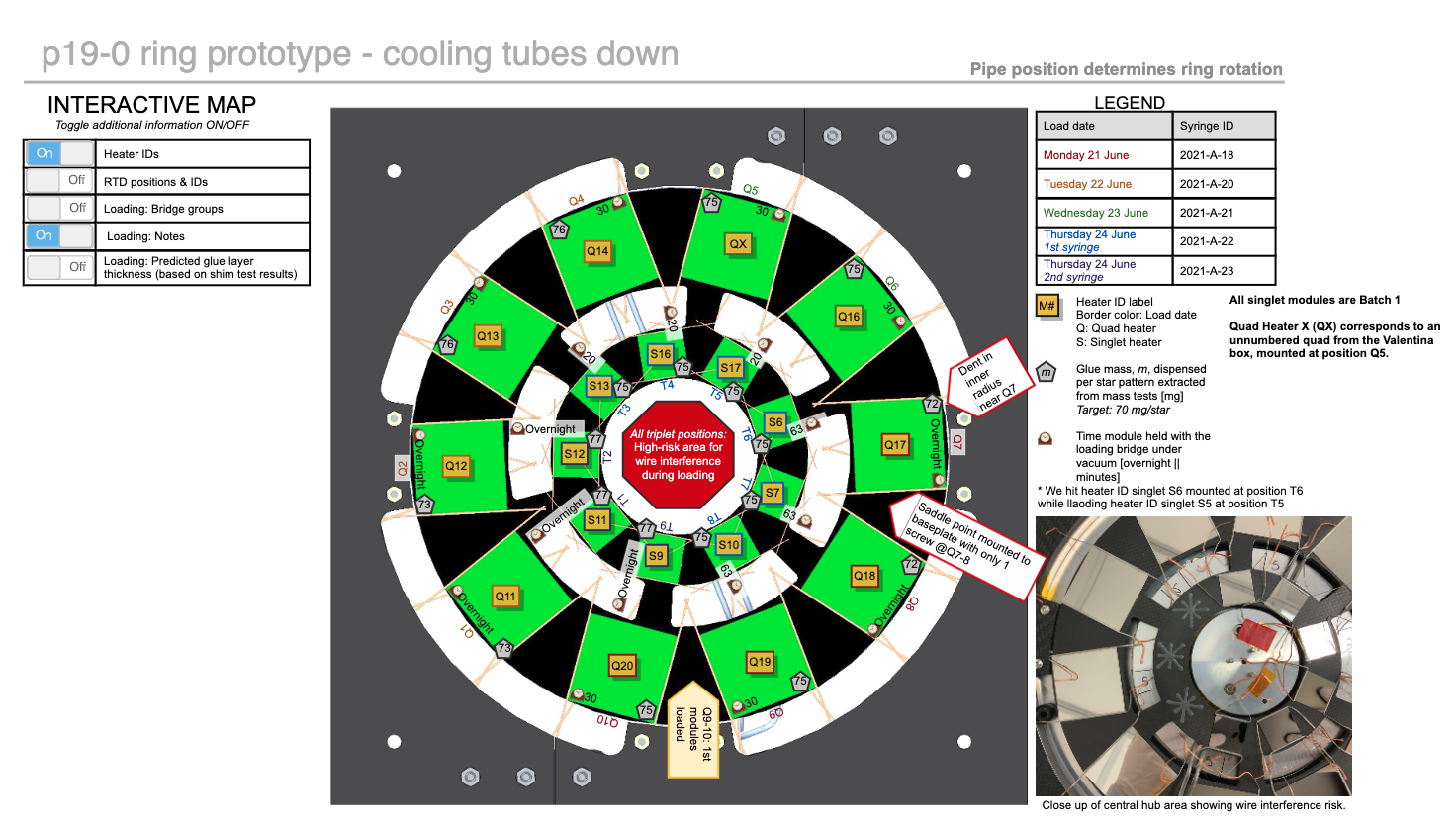

Screenshots from the Loading layers of the Interactive Map

Observations, properties, and measurements by Heater ID

Properties: Quads

| Properties – Heater ID: Quad, batch | #11 | #12 | #13 | #14 | #X | #16 | #17 | #18 | #19 | #20 | Uncertainty | Source |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Length (cm) | 4.108 | 4.107 | 4.100 | 4.102 | 4.100 (measured) | 4.100 | 4.110 | 4.100 | 4.101 | 4.107 | ±30 μm | Heaters.xlsx |

| Width (cm) | 4.259 | 4.248 | 4.259 | 4.252 | 4.245 (measured) | 4.245 | 4.242 | 4.247 | 4.245 | 4.249 | ±30 μm | Heaters.xlsx |

| Thickness (μm) | 312 | 312 | 315 | 315 | N/A | 318 | 303 | 303 | 303 | 303 | ±5 μm | Heaters.xlsx |

| Resistance when wires first bonded (Ω) | 2.5 | 2.4 | 2.4 | 2.2 | 2.5 | 2.3 | 2.3 | 2.5 | 2.6 | 2.4 | ±0.1 Ω | Heaters.xlsx |

| Resistance: mounted on ring, before spray painting (Ω) | Heaters.xlsx | |||||||||||

| Mass (g) | 1.521 | 1.545 | 1.568 | 1.577 | 1.553 | 1.551 | 1.564 | 1.549 | 1.553 | 1.556 | ± 0.001 g | Scale measurement on loading day |

| Module thickness at center, measured with micrometers (μm) | 302 | 303 | 303 | 302 | 303 | 302 | 305 | 302 | 304 | 302 | Micrometer measurement after cleaning on loading day | |

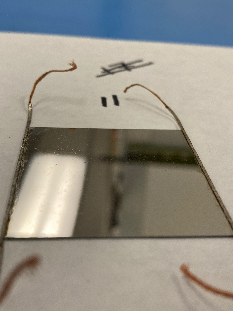

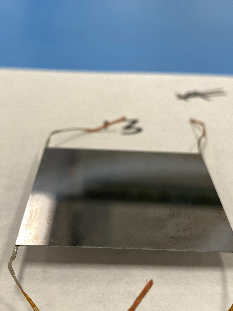

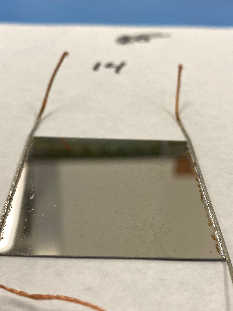

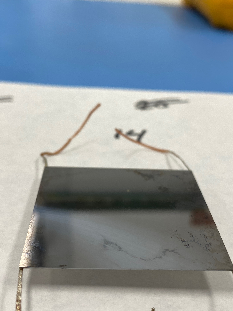

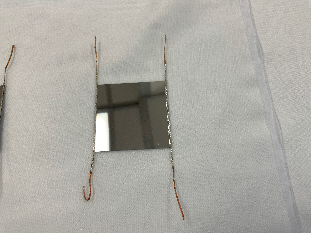

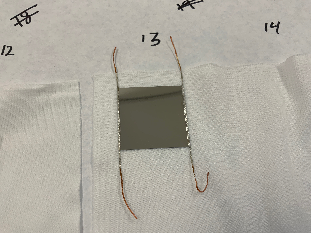

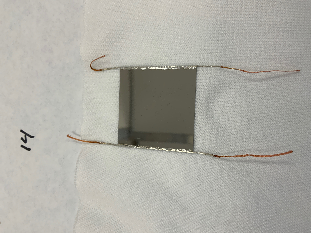

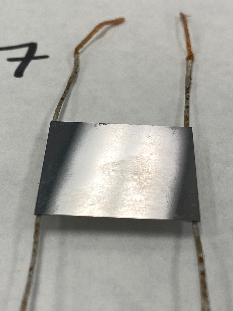

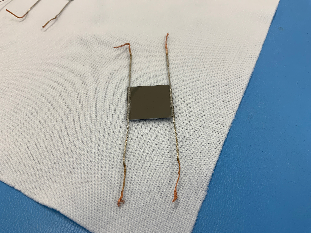

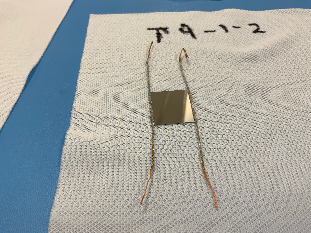

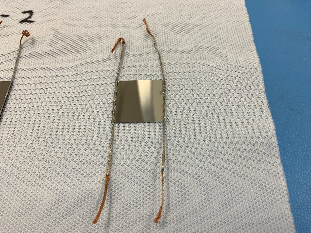

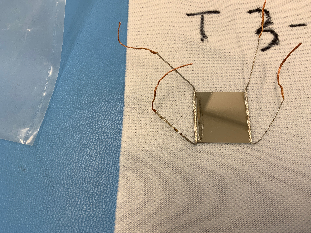

| Wire thicknesses, measured with calipers (mm) | 0.70, 0.69, 0.70, 0.72 (clockwise from top left in post-wash picture) | 0.68, 0.73, 0.71, 0.69 (clockwise from top left in post-wash picture) | 0.72, 0.70, 0.69, 0.72 (clockwise from top left in post-wash picture) | 0.71, 0.69, 0.72, 0.69 (clockwise from top left in post-wash picture) |

|

|

|

|

|

| ||

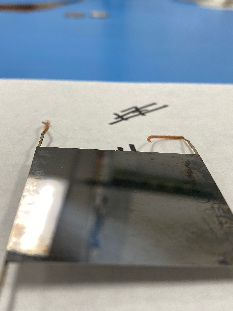

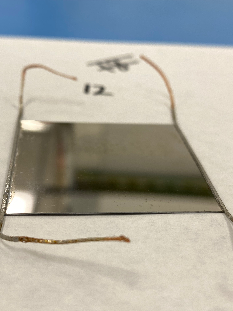

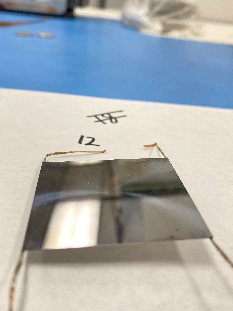

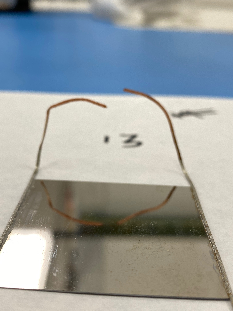

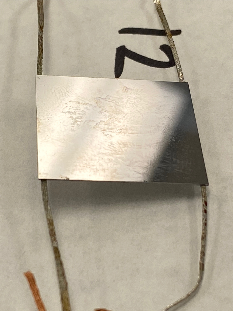

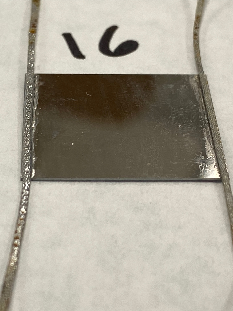

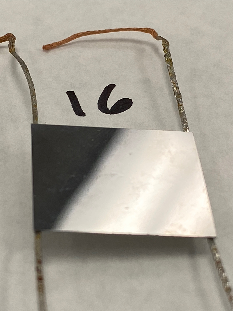

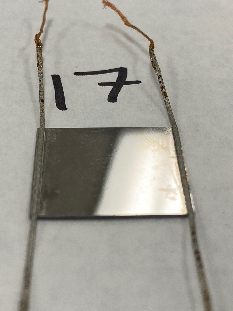

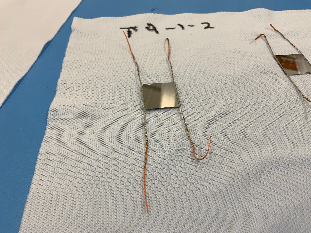

| Visual Inspection before loading | #11 | #12 | #13 | #14 | #X | #16 | #17 | #18 | #19 | #20 | ||

| Before IPA wash & dry rag polish | ||||||||||||

| After IPA wash & dry rag polish | ||||||||||||

| Retrieved from storage | 06/22 11 AM | 06/22 11 AM | 06/22 11 AM | 06/22 11 AM | 06/23 10:43 AM | 06/23 10:43 AM | 06/21 10:30 AM | 06/21 10:30 AM | 06/21 10:30 AM | 06/21 10:30 AM | ||

| Washing time | 06/22 11:15 AM Nico | 06/22 11:15 AM Nico | 06/22 11:15 AM Nico | 06/22 11:15 AM Nico | 06/23 11:25 AM | 06/23 11:29 AM | 06/21 10:40 AM Nico | 06/21 10:40 AM Nico | 06/21 10:40 AM Nico | 06/21 10:40 AM Nico | ||

| Comments | Fine | Fine | Best-looking of #11-14 | Worst-looking of #11-14. Heat damage (discoloration) backside. Validated resistance measurement. Wires frayed near soldering. Long wires, crooked wrt side of sensor. Surface scratched on left side | No obvious issues with this heater | No obvious issues with this heater | No obvious issues with this heater | Has some scum/scuff on the upper face left side, which we’re unable to remove by cleaning with IPA | No obvious issues with this heater | Has a chip on the top edge, near the right side | ||

| Loading experience | #11 | #12 | #13 | #14 | #X | #16 | #17 | #18 | #19 | #20 | ||

| Load date (mounting time) | 06/22 5:21 PM | 06/22 5:21 PM | 06/22 4:35 PM | 06/22 4:35 PM | 06/24 4:10 PM | 06/24 PM 4:10 PM | 06/24 3:00 PM | 06/24 3:00 PM | ||||

| Load position | QD1 | QD2 | QD3 | QD4 | QD7 | QD8 | QD9 | QD10 | ||||

Shim testing results | #11 | #12 | #13 | #14 | #X | #16 | #17 | #18 | #19 | #20 | ||

Expected glue layer thickness (μm) | 100-200 | 100-200 | 100-200 | 100-200 | 100-200 | ~200 | 100-200 | 100-200 | 100-200 | |||

100-μm shim | Enters | Enters | Enters | Enters | Enters | Enters | Enters with minimal resistance | Enters with minimal resistance | Enters with minimal resistance | Enters with minimal resistance | ||

200-μm shim | Blocked | Blocked | Blocked | Blocked | Enters at inner radius corner | Enters at inner radius corner | Enters, with significant resistance | Does not enter | Does not enter | Does not enter | ||

Glue batch | #11 | #12 | #13 | #14 | #X | #16 | #17 | #18 | #19 | #20 | ||

Syringe ID | 2021-A-20 | 2021-A-20 | 2021-A-20 | 2021-A-20 | 2021-A-21 | 2021-A-21 | 2021-A-18 | 2021-A-18 | 2021-A-18 | 2021-A-18 | ||

Date dispensed | 06/22 5:16 PM | 06/22 5:16 PM | 06/22 4:30 PM | 06/22 4:30 PM | 06/23 3:32 PM | 06/23 3:32 PM | 06/24 4:04 PM | 06/24 4:04 PM | 06/24 2:55 PM | 06/24 2:55 PM | ||

Dispensing | #11 | #12 | #13 | #14 | #X | #16 | #17 | #18 | #19 | #20 | ||

Estimated glue mass per star (mg) | 73.4 | 73.4 | 76 | 76 | 74.5 | 74.5 | 73 | 73 | 75 | 75 | ||

Averaged mass tests | #11-15 | #11-15 | #7-9 | #7-9 | #2-5 | #2-5 | #25-27 | #25-27 | #2-4 | #2-4 | ||

Time elapsed since syringe fully thawed (minutes) | 102 | 102 | 56 | 56 | 45 | 45 | 108 | 108 | 39 | 39 | ||

Minutes module held under vacuum (Hold time) | Overnight | Overnight | 30 | 30 | 30 | 30 | Overnight | Overnight | 30 | 30 |

Properties: Triplets

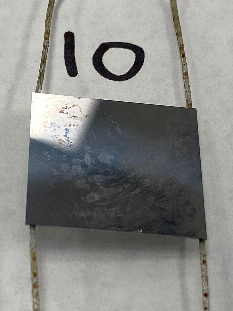

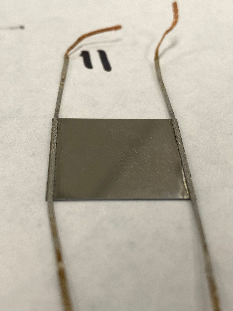

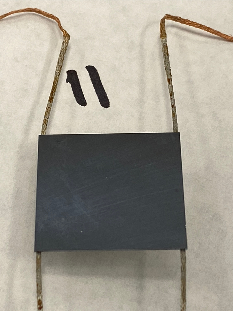

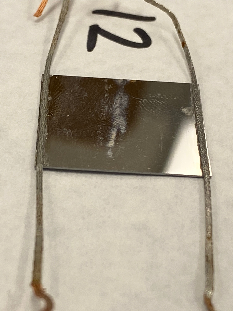

| Properties – Heater ID: Triplet, Batch 1 | #6 | #7 | #9 | #10 | #11 | #12 | #13 | #16 | #17 | Uncertainty | Source |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Length (cm) | 2.050 | 2.050 | 2.050 | 2.050 | 2.050 | 2.050 | 2.050 | 2.050 | 2.050 | ±30 μm | Heaters.xlsx |

| Width (cm) | 2.131 | 2.131 | 2.131 | 2.129 | 2.131 | 2.129 | 2.129 | 2.129 | 2.129 | ±30 μm | Heaters.xlsx |

| Thickness (μm) | 310 | 310 | 310 | 307 | 307 | 310 | 307 | 310 | 307 | ±5 μm | Heaters.xlsx |

| Resistance when wires first bonded (Ω) | 2.6 | 2.6 | 2.6 | 2.6 | 2.6 | 2.4 | 2.4 | 2.4 | 2.4 | ±0.1 Ω | Heaters.xlsx |

| Resistance: mounted on ring, before spray painting (Ω) | Heaters.xlsx | ||||||||||

| Mass (g) | 0.585 | 0.579 | 0.636 | 0.577 | 0.566 | 0.590 | (06/23: 0.655) 06/24 0.613 | 0.637 | 0.538 | ± 0.001 g | Scale measurement on loading day |

| Module thickness at center, measured with micrometers (μm) | 303 | 303 | 302 | 302 | 302 | 304 | 302 | 302 | 301 | Micrometer measurement after cleaning on loading day | |

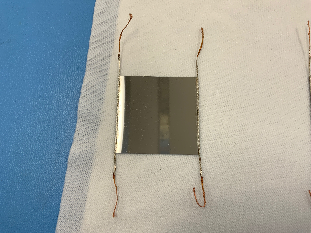

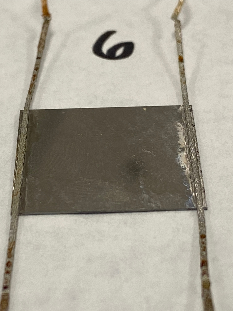

| Wire thicknesses, measured with calipers (mm) | 0.69, 0.67, 0.68, 0.68 (clockwise from top left in post-wash picture) | 0.71, 0.69, 0.72, 0.71 (clockwise from top left in post-wash picture) | 0.71, 0.69, 0.71, 0.70 (clockwise from top left in post-wash picture) | 0.64, 0.69, 0.69, 0.72 (clockwise from top left in post-wash picture) | 0.69, 0.68, 0.70, 0.69 (clockwise from top left in post-wash picture) | 0.69, 0.65, 0.69, 0.71 (clockwise from top left in post-wash picture) | 0.71, 0.67, 0.70, 0.71 (clockwise from top left in post-wash picture) | 0.81, 0.65, 0.70, 0.76 (clockwise from top left in post-wash picture) | 0.70, 0.73, 0.68, 0.68 (clockwise from top left in post-wash picture) | ||

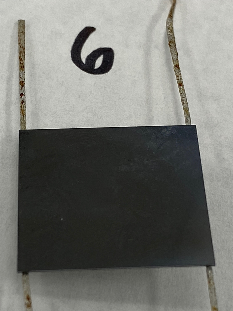

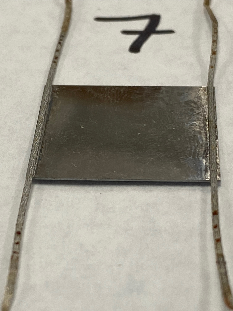

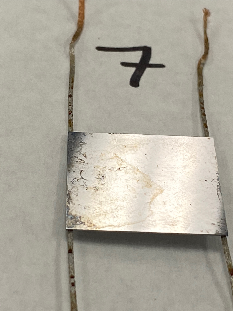

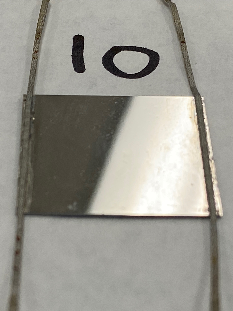

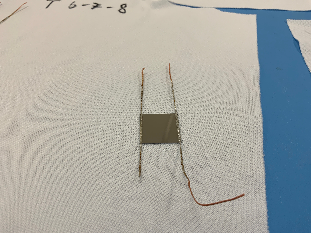

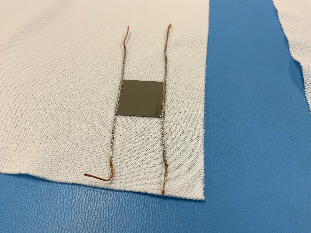

| Visual Inspection before loading | #6 | #7 | #9 | #10 | #11 | #12 | #13 | #16 | #17 | ||

| Before IPA wash & dry rag polish | |||||||||||

| After IPA wash & dry rag polish | |||||||||||

| Retrieved from storage | 06/24 9 AM | 06/24 9 AM | 06/24 9 AM | 06/24 9 AM | 06/24 9 AM | 06/24 9 AM | 06/23 10:43 AM; 06/24 9 AM | 06/24 9 AM | 06/24 9 AM | ||

| Washing time | 06/24 9:34 AM | 06/24 9:38 AM | 06/24 9:40 AM | 06/24 9:42 AM | 06/24 9:22 AM | 06/24 9:25 AM | 06/23 11:45 AM; 06/24 9:26 AM | 06/24 9:27 AM | 06/24 9:33 AM | ||

| Comments | Bottom left wire snapped after the soldered length | Seems great. Nico bent bottom left wire | Nico bent bottom right wire. Backface left side has several small chips along wired side. Super long wires. No pre-wash pictures. | Nico bent top left wire. Back top side has a small chip | Small chip on backside right | Small chip backside top side | 06/23:

06/24 Light, insignificant scratching on the backside, big skid mark on the left side on top side | Looked great. Nico bent the bottom left wire | Nico bent bottom left wire. Backside top side has a medium-sized chip along the edge | ||

| Loading experience | #6 | #7 | #9 | #10 | #11 | #12 | #13 | #16 | #17 | ||

| Load date (mounting time) | 06/24 3:17 PM | 06/24 3:17 PM | 06/24 4:49 PM | 06/24 3:17 PM | 06/24 4:49 PM | 06/24 4:49 PM | 06/24 2:42 PM | 06/24 2:42 PM | 06/24 2:42 PM | ||

| Load position | TD6 | TD7 | TD9 | TD8 | TD1 | TD2 | TD3 | TD4 | TD5 | ||

Shim testing results | #6 | #7 | #9 | #10 | #11 | #12 | #13 | #16 | #17 | ||

Expected glue layer thickness (μm) | 100-200 | 100-200 | 100-200 | 100-200 | 100-200 | 100-200 | 100-200 | 100-200 | 100-200 | ||

100-μm shim | Surfs | Surfs | Surfs | Surfs | Surfs | Surfs | slides under modules easily | slides under modules easily | slides under modules easily | ||

200-μm shim | Blocked | Blocked | Blocked | Blocked | Blocked | Blocked | fully obstructed | fully obstructed | fully obstructed | ||

Glue batch | #6 | #7 | #9 | #10 | #11 | #12 | #13 | #16 | #17 | ||

Syringe ID | 2021-A-22 | 2021-A-22 | 2021-A-23 | 2021-A-22 | 2021-A-23 | 2021-A-23 | 2021-A-22 | 2021-A-22 | 2021-A-22 | ||

Date dispensed | 06/24 3:15 PM | 06/24 3:15 PM | 06/24 4:47 PM | 06/24 3:15 PM | 06/24 4:47 PM | 06/24 4:47 PM | 06/24 2:39 PM | 06/24 2:39 PM | 06/24 2:39 PM | ||

Dispensing | #6 | #7 | #9 | #10 | #11 | #12 | #13 | #16 | #17 | ||

Estimated glue mass per star (mg) | 74.7 | 74.7 | 76.5 | 74.7 | 76.5 | 76.5 | 75 | 75 | 75 | ||

Averaged mass tests | #10-12 | #10-12 | #20'-21' | #10-12 | #20'-21' | #20'-21' | #5-6 | #5-6 | #5-6 | ||

Time elapsed since syringe fully thawed (minutes) | 90 | 90 | 52 | 90 | 52 | 52 | 57 | 57 | 57 | ||

Minutes module held under vacuum (Hold time) | 63 | 63 | Overnight | 63 | Overnight | Overnight | 20 | 20 | 20 |

Loading experience

Loading order (QD = "Quad down"; TD = "Triplet down")

| Date | Personnel | Syringe ID | Modules | Photo album | Records |

|---|---|---|---|---|---|

| 2021-06-21 | Rachel, Nico, Josh (observing) | 2021-A-18 | quad #19 : QD9 & quad #20 : QD10 quad #17 : QD7 & quad #18 : QD8 | https://photos.app.goo.gl/9TjMexS3qjaFo5Mi8 | https://atlascr.slac.stanford.edu:8080/Clean+Room+Activities/74 |

| 2021-06-22 | Hannah, Nico, Josh (observing) | 2021-A-20 | quad #13 : QD3 & quad #14 : QD4 quad #11 : QD1 & quad #12 QD2 | https://photos.app.goo.gl/jv9XFrViMNAmFj2H6 | |

| 2021-06-23 | Rachel, Nico | 2021-A-21 | quad X : QD5 & quad 16 : QD6 | https://photos.app.goo.gl/JC9KY44MKsRAjGWK9 | https://atlascr.slac.stanford.edu:8080/Clean+Room+Activities/76 |

| 2021-06-24 | Hannah, Nico, Joshua (observing) | 2021-A-22, 2021-A-23 | All triplets T345 B1 #13 : TD3, B1 #16 : TD12, B1 #17 : TD5 T678 B1 #6 : TD6, B1 #7 : TD7, B1 #10 : TD8 T912 | https://photos.app.goo.gl/pE2V1kYvqVuwVrGRA |

Metrology

Link to slides showing results of heater x,y measurements https://docs.google.com/presentation/d/1ZdiT7JzgxqH46K8tOTxdChammp0vxplUcT0MfgkjaGo/edit?usp=sharing