This pages collects links and information on the studies done so far at SLAC for Thermal Testing (and related instrumentation).

If anything is unclear, please contact vcairo@slac.stanford.edu.

Thermal Analysis (July 30th 2021):

Please, take a look here https://gitlab.cern.ch/slac_itk/thermalimageprocessing and if you have questions, drop an email to valentina.maria.cairo@cern.ch

Summary of RTD routing, orientation of the heaters, RTD module debugging (May 6th 2021):

https://cernbox.cern.ch/index.php/s/uJ9cUjJ4Cjf2bwN

Summary of RTD calibration (April 2021):

https://cernbox.cern.ch/index.php/s/YwALbwv7fKJ9AWQ

Test on Bare Local Support with active cooling system (July 8th 2020):

| Picture | Description |

|---|---|

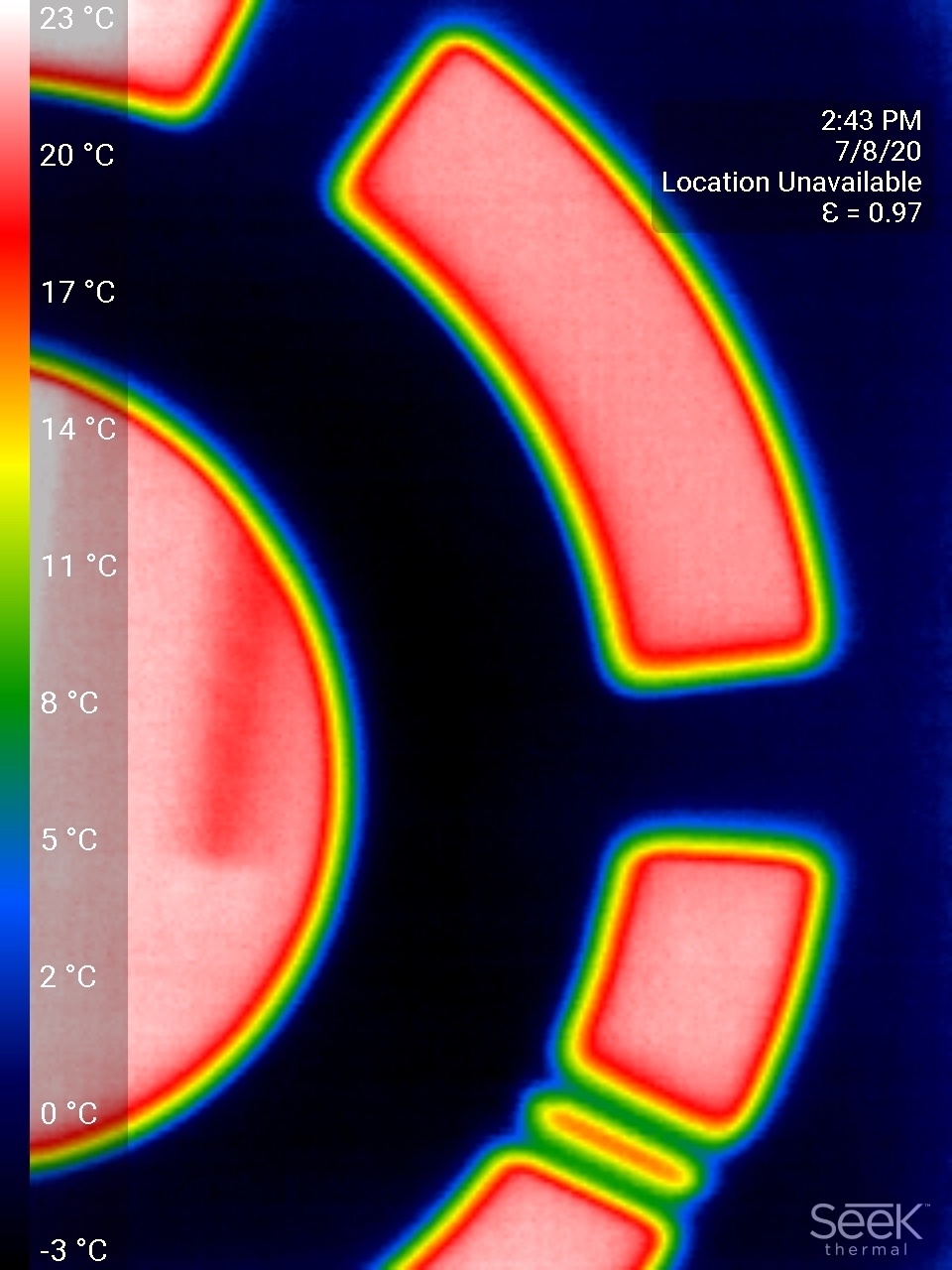

Local Support at the start of the cooling process (2:43 pm, 7/8/20). The minimum temperature read in the local support is about -3 ºC. To understand the structure, please compare the IR camera picture with the picture below from the visible light camera. | |

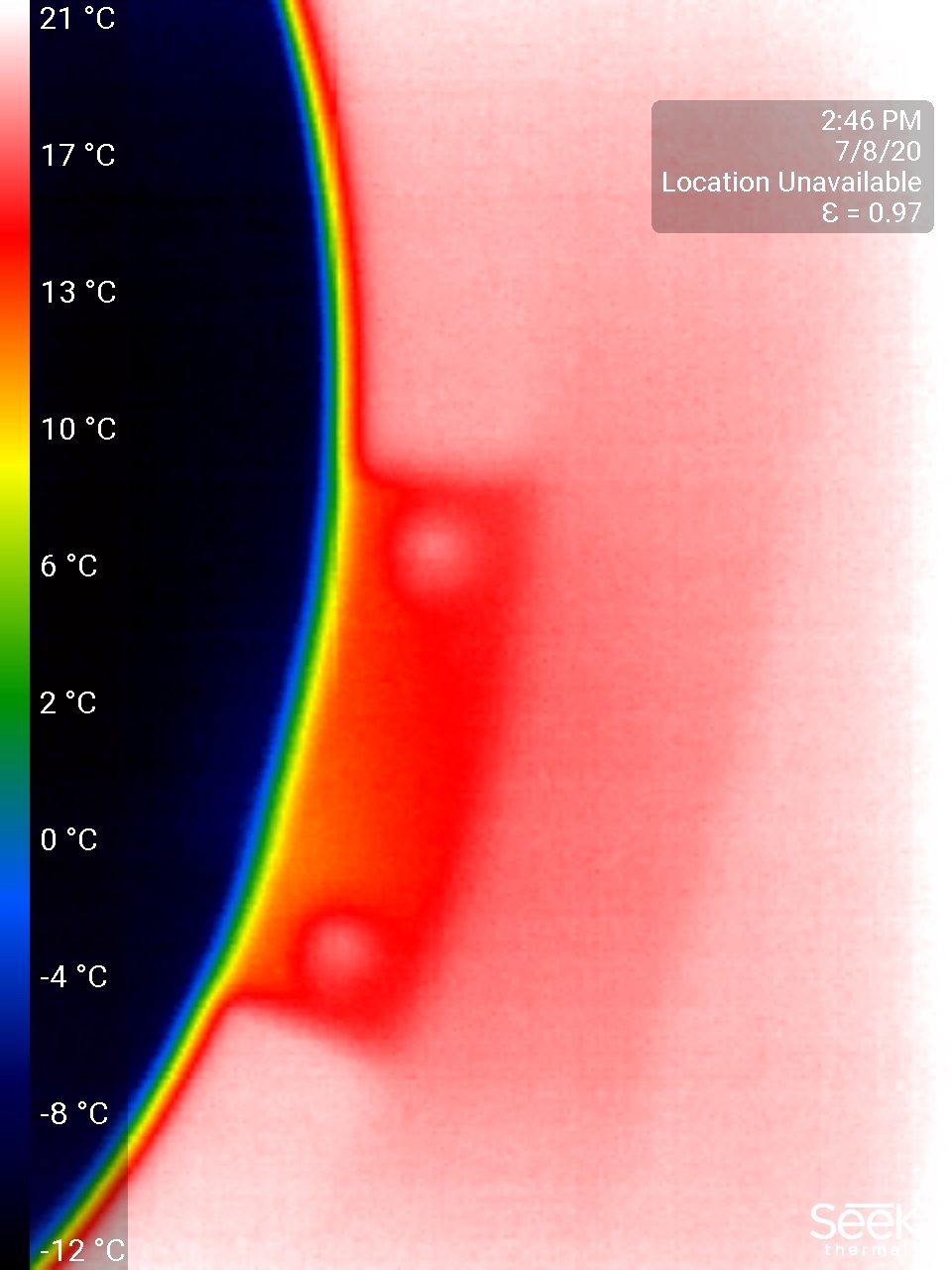

| Detail of the handling frame. | |

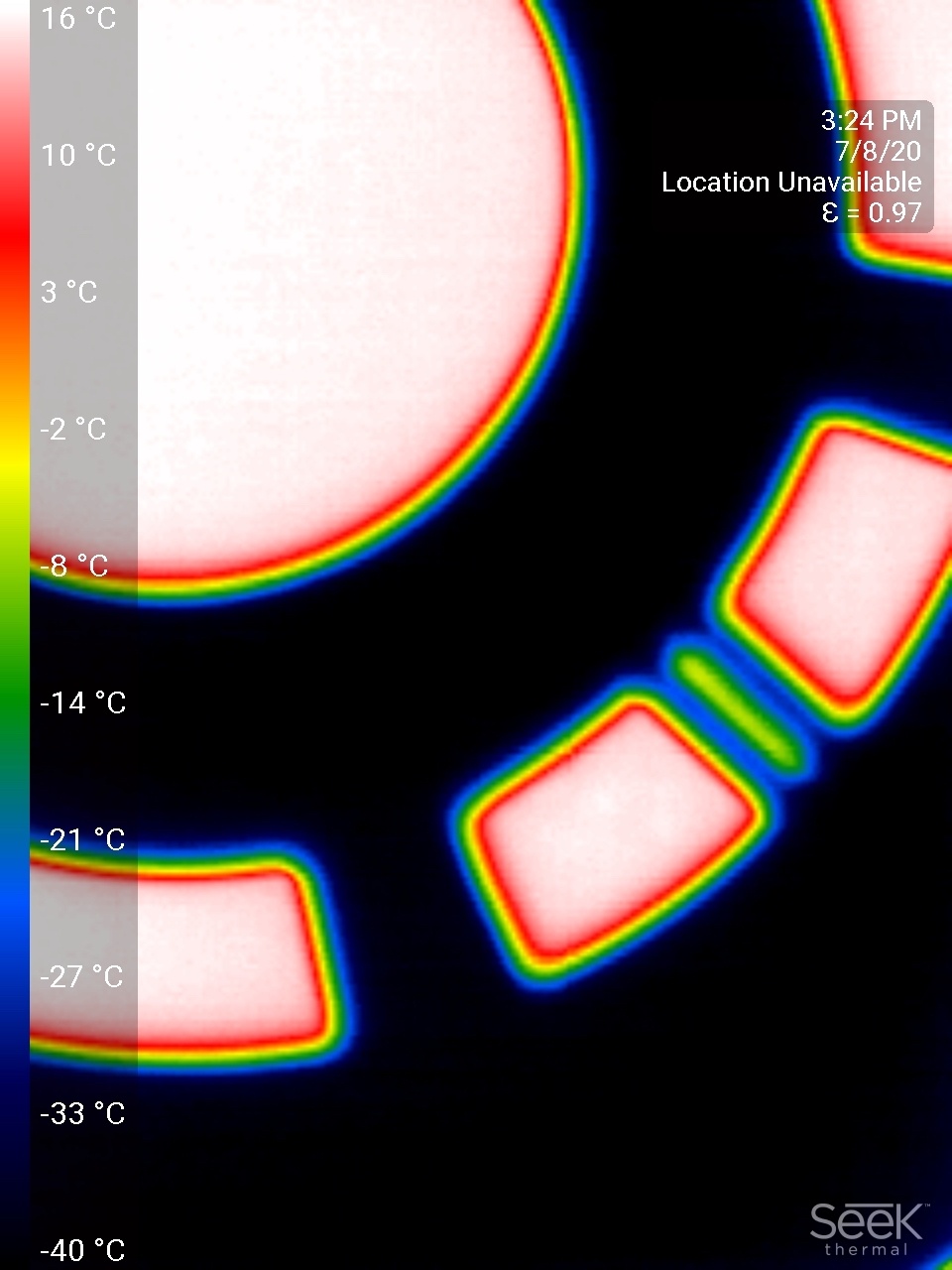

Local Support after about half an hour of cooling on (3:24 pm, 7/8/20). The minimum temperature read in the local support now is about -40 ºC. | |

| Video of the IR camera view while moving it with the Gantry system. |

Status of IR camera readout and offline analysis (as of May 21st 2020):

We are able to read the temperature per pixel via the App on the Samsung S7 with the Full Frame Option.

A TIFF file containing all the info is saved and can be read in the offline image processing, which was developed. This is able to identify the heater out of a certain background through contour finding (tested on a single Peltier and on CAD sketches, will be fully tested once back at SLAC) and return temperature distributions. It was validated against temperature read in from an RTD. See slides below for more details.

An alternative read-out system with built in calibration functions to read the camera directly from a computer and get rid of the phone is being developed in parallel.

Status of RTD readout (as of May 21st 2020):

5 three-wire RTD modules available (this give a total of 5x8 = 32 channels that can be read in). 3 of these modules were inherited from nEXO, 2 were bought just before the COVID19 shutdown, so they have not yet been tested.

1 four-wire RTD module is also available (this could be used to read in the cooling plant RTDs and get rid of the current Labview based system).

Status of Monitoring (as of May 21st 2020):

The monitoring system developed for the B33 low-temperature freezer (used for thermal-conductive glue storage) can be used to read in and monitor the P19-0 RTDs.

An example with a single RTD was tested quickly before the shutdown, it will be fully tested once access to the lab is permitted again.

Link to Webpage: https://www.slac.stanford.edu/~vcairo/

Link to Grafana page: http://atlascr:3000 (se slides below on Monitoring System for login instructions).

Status of DCS/Interlock (as of May 21st 2020):

To be checked. Latest presentation here.

Status of equipment for P19-0 testing (as of May 21st 2020):

| Item | Power Supplies | RTDs | RTD NIM modules | IR Cameras | Phone | Heaters | Gantries |

|---|---|---|---|---|---|---|---|

| Quantity | 4, more precisely 1 (60V, 3.3 A) and 3 (40V, 5 A). | ~50 | 5 three-wire plus 1 four-wire | 2 | 1 | Enough wired single and quad heaters to load a ring and a stave (see excel document below for details). | 2 |

| Notes | The preferred (low current) configuration is 4 powering lines: 2 lines on each side of the ring, 1 for the quad and 1 for the single. The ideal would be to get 2 identical power supplies for the quads and 2 for the singles, while right now we have one of a type and 3 of another. | ready to be wired appropriately for the test box patch panel (which has connectors HD15 F), will be done by the Electronic lab | the 1 four-wire can be used for the CO2 plant | 1 is (probably) faulty | Samsung S 7 (link) | More available (to be wired) | Installed in the test box |

=============================================================================

Presentations at SLAC ITk construction meeting (from most recent, in 2020):

Monitoring System: https://indico.cern.ch/event/918664/#11-test-box-equipment-and-plan

Image Offline Analysis: https://indico.cern.ch/event/896700/#11-test-box-equipment-and-plan

RTD Readout and IR camera: https://indico.cern.ch/event/892184/#11-test-box-equipment-and-plan

RTD Readout and IR camera: https://indico.cern.ch/event/890376/#11-test-box-equipment-and-plan

RTD Readout and IR camera: https://indico.cern.ch/event/887554/#11-test-box-equipment-and-plan

Long presentation on Test Box Commissioning with emphasis on Powering Strategy for heaters: https://indico.cern.ch/event/885168/#11-test-box-equipment-and-plan

Issues with the IR camera #1 https://indico.cern.ch/event/884015/#11-heaters-and-test-box-equipm

First tests with IR camera #1 https://indico.cern.ch/event/881601/#11-heaters-and-test-box-equipm

=============================================================================

Presentation at US ATLAS ITk Pixel workshop (Jan 2020):

https://indico.cern.ch/event/860295/contributions/3683617/

=============================================================================

Google doc for test-box equipment:

https://docs.google.com/document/d/1JioOlMDXLMGPRwHgNxSUj8S7WsYkRZXpED-ogqVNVzM/edit

=============================================================================

Excel spreadsheet for RTD vs IR Camera's testing (short version):

=============================================================================

Excel spreadsheet for heathers:

https://docs.google.com/spreadsheets/d/1s-4BwTW910EQzInhqSd7pgCI3uvk52Jl/edit#gid=2064913736

=============================================================================

Gantry System Software:

https://software.openbuilds.com/#