Content:

Introduction:

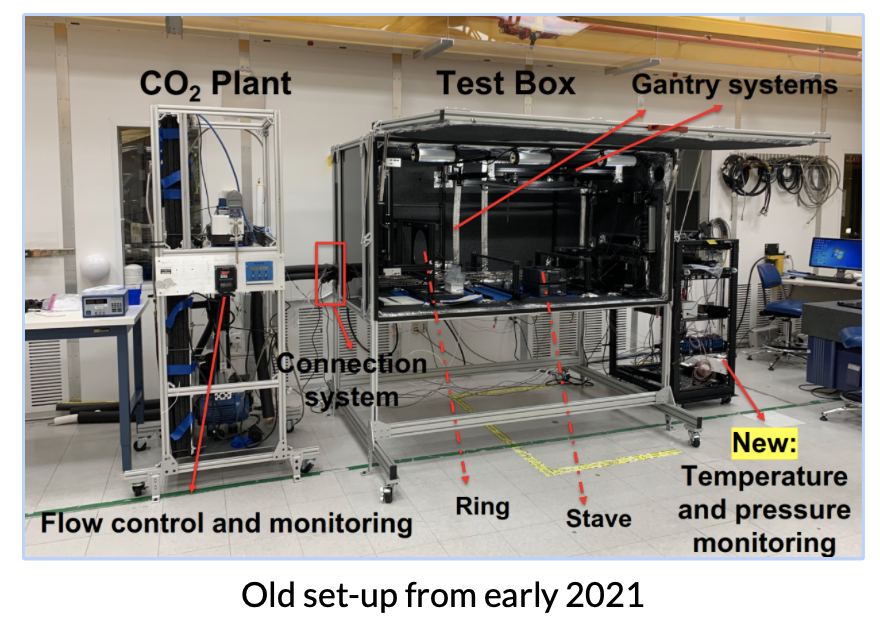

CO2 cooling system will be used to prevent thermal runaway, and is one part within the QC Box.

CO2 plant Plumbing and Instrument Diagram

The major components and pressure rating of the CO1 plant are shown in List of Travelers

Instrument of the CO2 plant

•Flowmeter

RHEONIK RHE15

Data sheet: https://www.rheonik.com/wp-content/uploads/pdf/Rheonik_Coriolis_RHE15-14EZB_Datasheet.pdf

Operation manual: http://www.rheonik.com/wp-content/uploads/pdf/RHE15_Operation_Manual.pdf

•Pressure Transmitter

Aschraft or Omega PX309-1KGI

Overview: http://www.farnell.com/datasheets/2339490.pdf?_ga=2.95005912.592500776.1579803090-155974585.1579803090

•Temperature Sensor

Omega PT100 RTD Probe.

Overview: https://assets.omega.com/pdf/test-and-measurement-equipment/temperature/sensors/rtds/PR-11.pdf

List of Travelers

| Number | Title and Link | Author | Date Modified |

|---|---|---|---|

| ATLAS CO2-100 | ATLAS CO2-100 High Pressure Decay Test.docx | Brian Qiu | 8 July 2020 |

| ATLAS CO2-101 | ATLAS CO2-101 Evacuation and CO2 Filling Procedure.docx | Brian Qiu | 3 June 2020 |

| ATLAS CO2-102 | ATLAS CO2-102 operation of the Julabo chiller .docx | Brian Qiu | 8 July 2020 |

| ATLAS CO2-103 | ATLAS CO2-103 Startup and Shut Down of the CO2 Plant 7-9.docx | Brian Qiu | 9 July 2020 |

| ATLAS CO2-104 | Brian Qiu | 18 Nov 2021 | |

| ATLAS CO2-105 | CO2 Operation hazard for CO2 Plant in B33 | Zhi Zheng | 18 Nov 2021 |

| ATLAS CO2-106 | CO2 operation spreadsheet | Zhi Zheng | 18 Nov 2021 |

| pressure system number of 1433 | 2014 |

Manual for VFD: https://www.hitachi.us/supportingdocs/forbus/inverters/Support/WJ200_Instruction_NT325X.pdf

CO2 Operation hazard table

The harzard of CO2 are summarized in the table as well as in the ATLAS CO2-105:

| Failures | comments | unmitigated consequence | mitigation |

| pressurize the CO2 plant to over 1000 psig | A pressure of higher than 1000 psig exceeds the rated pressure of some components of the CO2 plant | Leaks and release of high-pressure gases; damage system; potential projectiles injuring personnel | The pressure at the CO2 cylinder is the saturated pressure of the CO2. At 25 degC, the pressure is 918 psig, for CO2 plant it will be lower than 1000 psig at room Temperature |

| valve of CO2 cylinder is not at fully close position after filling | Leaks and release of high-pressure CO2 | Procedure 100 step 2050 requires valve to be closed | |

| when connected to a vacuum pump, the CO2 plant has not vented or the pressure gauge doesn't show zero gauge pressure | Damage to the vacuum pump can occur and personnel injury can happen if this step is not followed. | Procedure 101 step 1010 includes a check of pressure gauge and make sure it shows zero, before connected to a vacuum pump | |

| run the gear pump when there is no liquid CO2 in the system | Running the gear pump without liquid can damage the gear pump due to overheating. | Operation Training includes emphasis: make sure the system pressure is at 800 psi before turning on the pump. Procedure 103 includes this verification step 1010 | |

| run the chiller with a setpoint at lower than -52C for CO2 cooling | CO2 has a triple point of -56.6 C and chiller will adjust the heat transfer fluid temperature around the setpoint, in this case CO2 might become dry ice | CO2 might become dry ice and block the pipe, might cause damage on the gear pump | Operator training. |

| 800 psi CO2 piping leak at local support ( stave or ring ) at Room Temp with 800 psi | Energy for the stave with 800 psi at RoomT is around 3.5 J (with tube length ~200 mm) and for the ring, the energy is around 16 J, the energy is very small | small broken pieces flashing out could impact one's eyes | wear safety glasses until sure there are no leaks; Close QC box during operation. |