...

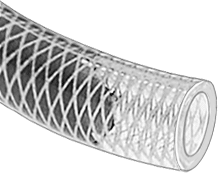

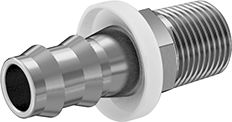

- A) Application section (2*140cm): Our application tubing came with the CERN shipment is a Saint Gobain Tygon S3 E3603 NSF-51 with 8mm ID/11.5mm OD that fit well onto the cooling block barb (ridge ID/OD=0.306"/0.363"=7.8/9.2mm). To avoid adapting metric-Imperial tubing, we also tried a 1/4" soft tubing and that seemed to just about being able to get on the cooling block barb with very tight fit. Since we may never dissemble the cooling block after initial assembly, we opted to go with the 1/4" ID and 3/8" OD tubing so that the two ends can fit onto the Swagelok Instrumentation quick connect QC6-316 (SS-QC6-D-600 / SS-QC6-B-600) with 3/8" fitting. Aiming for the same soft PVC Tygon chemical tubing as the original CERN part with ID/OD=1/4"/3/8" corresponds to McMaster-Carr #5155T26. Do we need a shut off valve near module to allow faster warmup ?

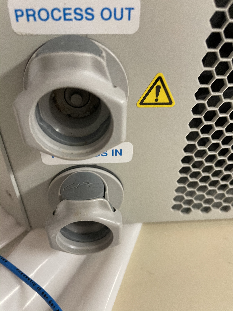

- B) Application joint to chiller Process In (30+15cm): Application joint is QC6-316 (SS-QC6-D-600 / SS-QC6-B-600 ) as for A) with 3/8" OD tube (McMaster-Carr #5155T26) for ~30cm then transition (with McMaster-Carr #91355K32) to a short (~15cm) 3/8" ID tube (McMaster-Carr #5155T34) to fit onto the 3/8" hose barb from the HFC 12 series (rating only down to 0C ?) which can connect with the 3/8" CPC at chiller Process In.

- C) Application joint to filter (or Process Out) (30+15cm): similar piece like B), such that the hose barb end can plug directly into the chiller Process Out, or filter out.

- D) Filter: The nominal filter appeared in ThermoCube's manual is with the Pentair/Pentek polypropylene housing which has 3/4 NPT female interface. Other auxiliary components also can be found at Grainger: Mounting bracket, wrench. ThermoCube recommended filter cartridges are the 5 micron particle filter which can be selected from the list. Also needs caution whether filter is compatible with <0C coolant. The filter output end should be fitted with the 3/4" NPT shutoff as those on the chiller unit. Filter inlet can also apply CPC with 3/4" NPT shutoff to transition to 1/2" tube over the 3/8" hose barb to connect to the chiller Process Out, with same connection at both ends.

- E) Jacket insulation: We need to insulate all sections of tubing with foam jacket to allow running coolant <~0C. It may be simplest to use a long continuous slitted piece with large enough radius.

Tables for chiller cycle tubing connection:

| From process out (chiller) to filter | |||||

| Coolant connector (3/8" CPC) on unit #2 (PROCESS OUT) | 3/8" Hose Barb HFC 12 Series Polypropylene Elbow Coupling Insert - Shutoff: link | 3/8" ID 1/2"OD tube(E-3603 Tygon PVC Tubing for Chemicals) link 45 cm (?) | 3/8" Hose Barb HFC 12 Series Polypropylene Elbow Coupling Insert - Shutoff: link | 3/4" NPT HFC 12 Series Polypropylene Coupling Body - Shutoff link | 3/4 NPT female interface link |

|---|---|---|---|---|---|

...

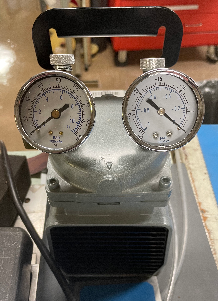

| GAST DOS-P704-AA | Left pump port with 3/8" barb |

|---|---|

Table for vacuum unit connections

| Left pump port with 3/8" barb | High-Pressure Firm Polyurethane Rubber TubingID:OD=3/8":5/8" Link ~1.5 m | 316 Stainless Steel Push-on Hose Fitting for Air and Water3/8" Hose ID, 1/4 NPT Male End Link | On/off valve High-Pressure Compact 316 Stainless Steel On/Off Valvewith Lever Handle, 1/4 NPT Female x 1/4 NPT MaleLink | 1/4" Tee316 Stainless Steel Threaded Pipe FittingLow-Pressure, Tee Connector, 1/4 NPT Female | Plastic Barbed Tube Fitting for Air and WaterSwivel Adapter, for 1/16" Tube ID (1.6 mm)x 1/4 NPT Male | cern tube OD/ID=3mm/1.8mm (~30cm) |

|---|---|---|---|---|---|---|

to be connect to Remotely monitor vacuum: |

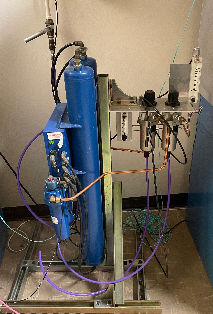

Dry Air

The dry air filters were saved by Matt from BaBar, residing inside the curtained area of B84 EPP lab. House compressed air are filtered to let out through the flow meter with a max flow of 20 ft3/min. A 80ft long hard polypropylene tubing with 1/4" OD (McMaster-Carr #9349T2) takes the drive air down to the ATLAS benches. The dry air supply tube terminates at a diverting valve (no shutoff) (McMaster #45165K42) on the bench to allow the switching of the dry air between a test port and the through path to module cooling unit. The through path continues with the same type of tube to transition to the 30cm long dry air tube into the module cooling unit which is an ID/OD=1.8mm/3.0mm blue tube from CERN shipment (same as the vacuum tube). This transition uses a similar strategy as the vacuum tubes, with a pair of Aluminum low-pressure 1/4 NPT adaptor to barbed tube fitting: 1/4" barb - male NPT (with O-ring) on supply side (McMaster-Carr #5058K441); 1/16" barb and female NPT on module side (McMaster-Carr #5058K641). The initial turn on of dry air should let run for a few hours with the outlet going to the test port using the diverting valve. Check flow and humidity at the test port before flowing into the module cooling unit. Once on for operation, the dry air flow should not be turned off. From an off state, the restart should always have the few hours of initial flush first. During operations, if the dry air needs to be off at the module cooling unit, use the diverting valve to temporarily directing the air to the test port. |

|---|

...