...

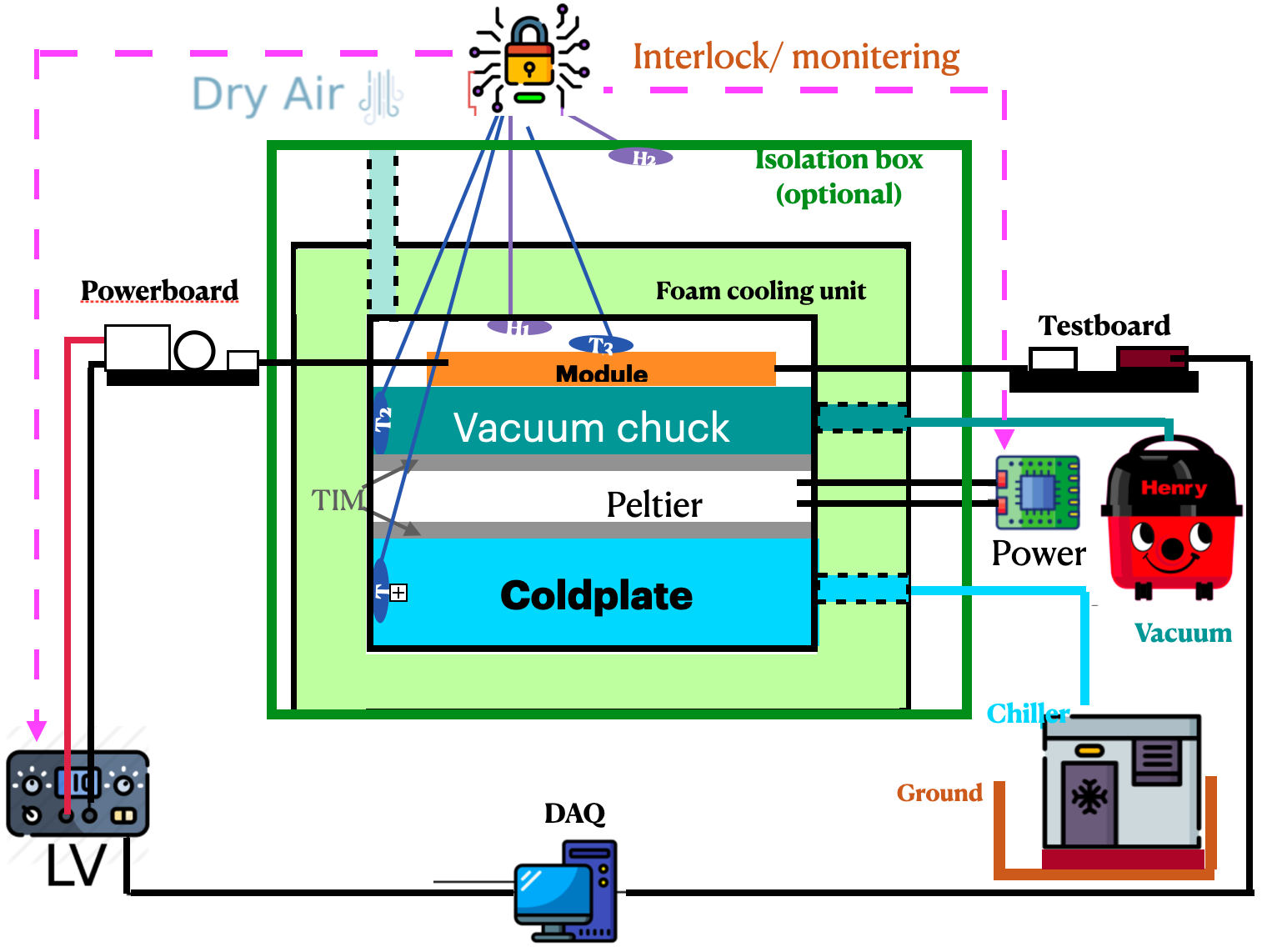

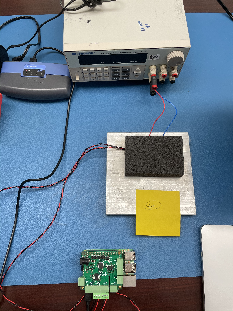

Module QC cooling test setup:

Module:

- Stage 1: test with dummy module ( now we have 6 quards and 1 singlet)

- Stage 2: test with module

...

- Overheating = the chiller fails and the PS keep running

- temperature on the cold plate

- Condensation = Dry air fails, moisture condense and destroys the device

- dew point < air temperature

- module temperature drop ←55C

- communication => fail safe

Chiller

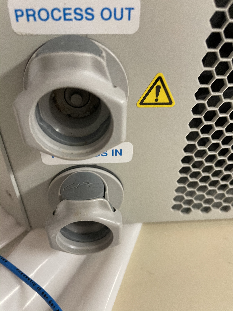

| Connector | Connection to the filter |

|---|---|

Thermo Cube: Chiller manual

...

The exact model of the ThermoCube we are working with is 10-400-3G20-1-CP2-R2-LT-AR which I think means: 400W capacity, >3 lpm @ 30 psig magnetic drive gear pump, with adustable flow setting for 2 lpm, 3/8" CPC shutoff valve, RS232 interface, low temp op (<5 deg C) and auto restart software.

This might an old model which doesn’t say what type of cold plate it is. Stainless would have carried a tag ’S” some where so this may be old style anodized AL PCW plate ? Koolance claims to be friendly with both Al and SS.

...

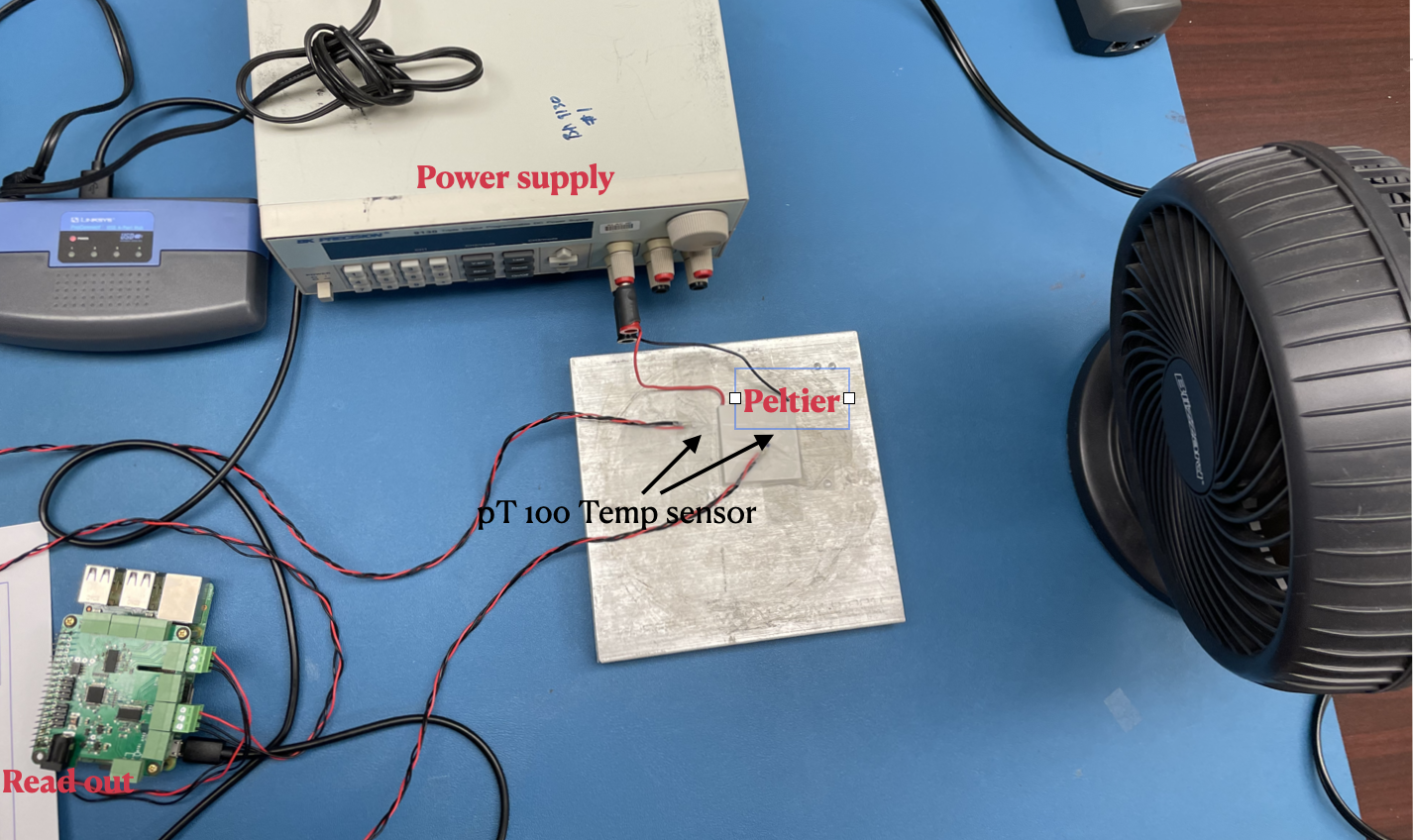

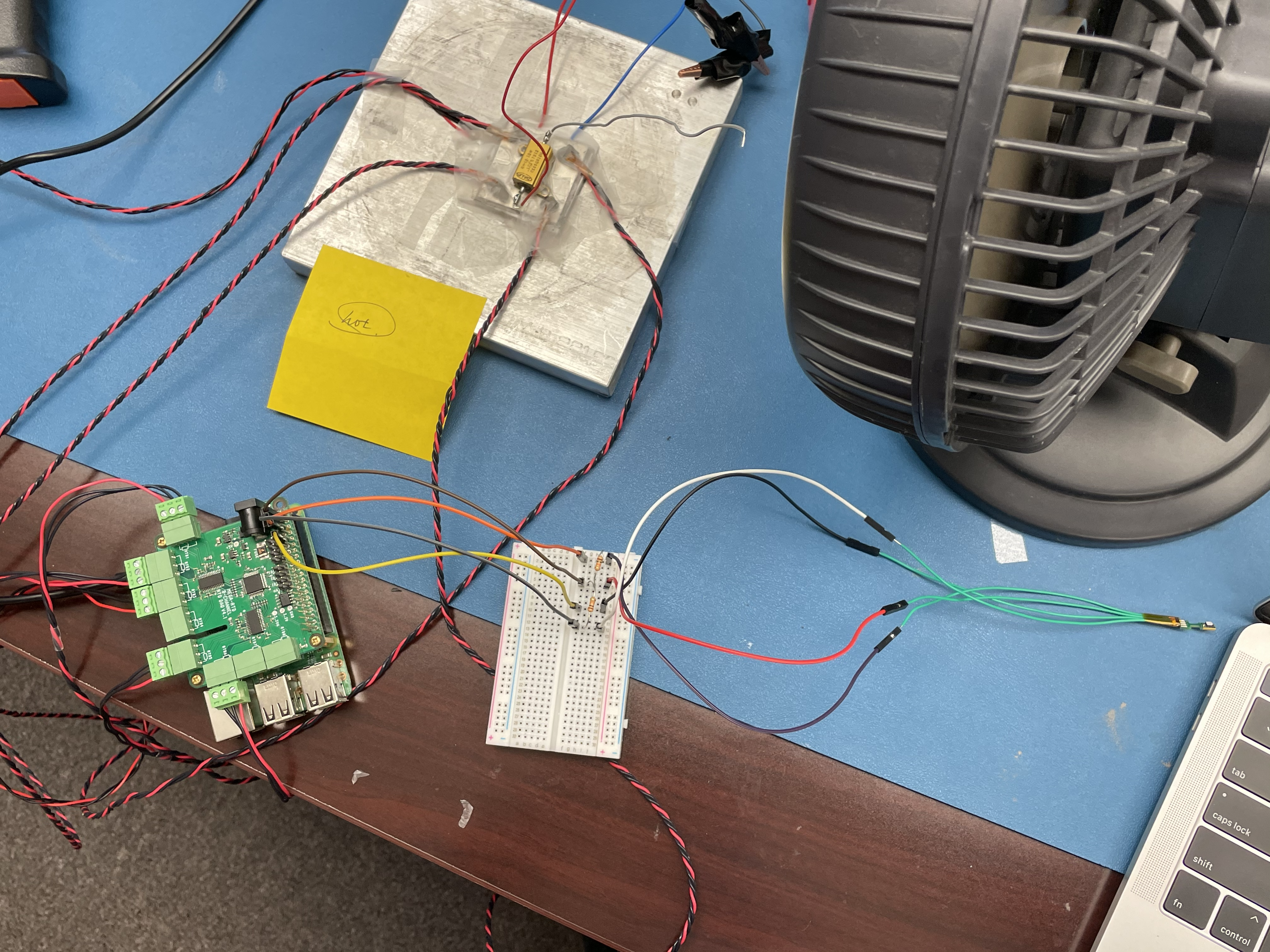

Preliminary Setup and Test Result

Empty load step up | With Heater | with foam box |

|---|---|---|

Results

- Check the Temperature distribution on the Peltier, temperature distribution is not flat on the cold side of Peltier while running the Peltier

- foam box can help isolate the Peltier system and increase the temperature difference between hot side and cold side

- running load will increase the temperature on the cold side

...