...

power supply:

current / voltage: 0-10A / 0-32V

Wiener Mpod (2channel, HV/LV)

Rohde and Schwarz HMP4040

Monitoring:

Temperature: NTC

Humidity (inside cooling unit): SHT85, (+/- %RH and +/- 0.1 C)

Humidity (inside cold box): Thorlabs TSP01 (+/- accuracy)

Arduino Mega 2560

Cooling:

Cooling unit: qual cooling unit v5

Chiller: Julabo HL CF41

Coolant: 100% silicone oil

Dry, room temperature nitrogen

Room temperature vacuum

TIM sheet: Panasonic EYG-S0909LZX2

TEC combination:

TEC 1: Larid 1081611050003

TEC 2: Larid 387004685

Components :

version 1: List of components:

https://docs.google.com/spreadsheets/d/1dNT5ja_pFS2P6HJojZd5K-uXMyx7_lAjD4M-GH4URZ4/edit?usp=sharing

Apr 22 2021 List of component:

https://docs.google.com/spreadsheets/d/1BgjfFbXAt-ffoCWYGcLghxHP21pGV1TTFr1I7jS42yg/edit#gid=0

Quad Cooling Unit Component Collection Status

...

To avoid condensation on the peltier devices, you must maintain a dry atmosphere in the cooling unit whenever there is coolant flowing through the coldplate. If condensation forms on the peltier devices, it will degrade the performance of the cooling unit because ice and water is an excellent conductor of heat. Getting rid of this condensation requires a long term “bakeout” of the coldstack and is best avoided.

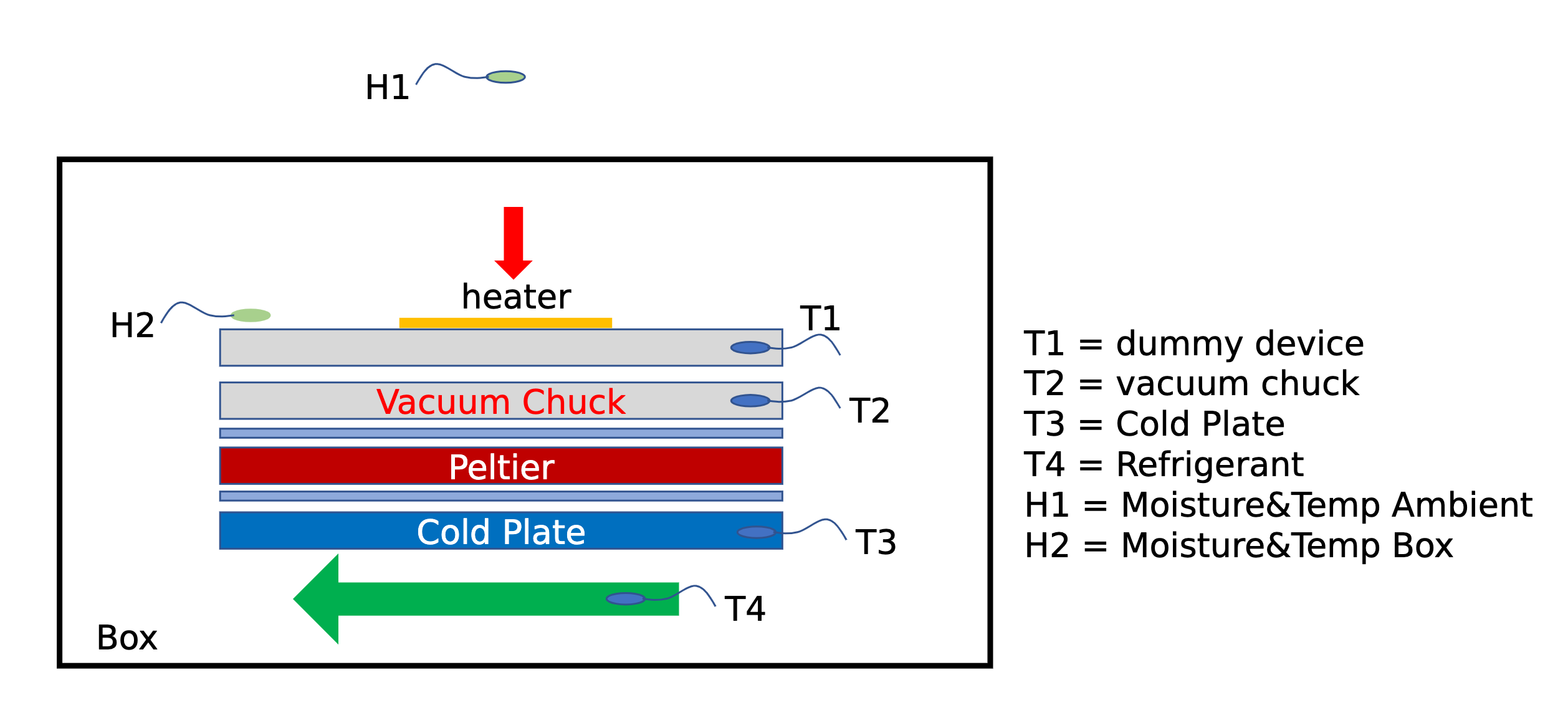

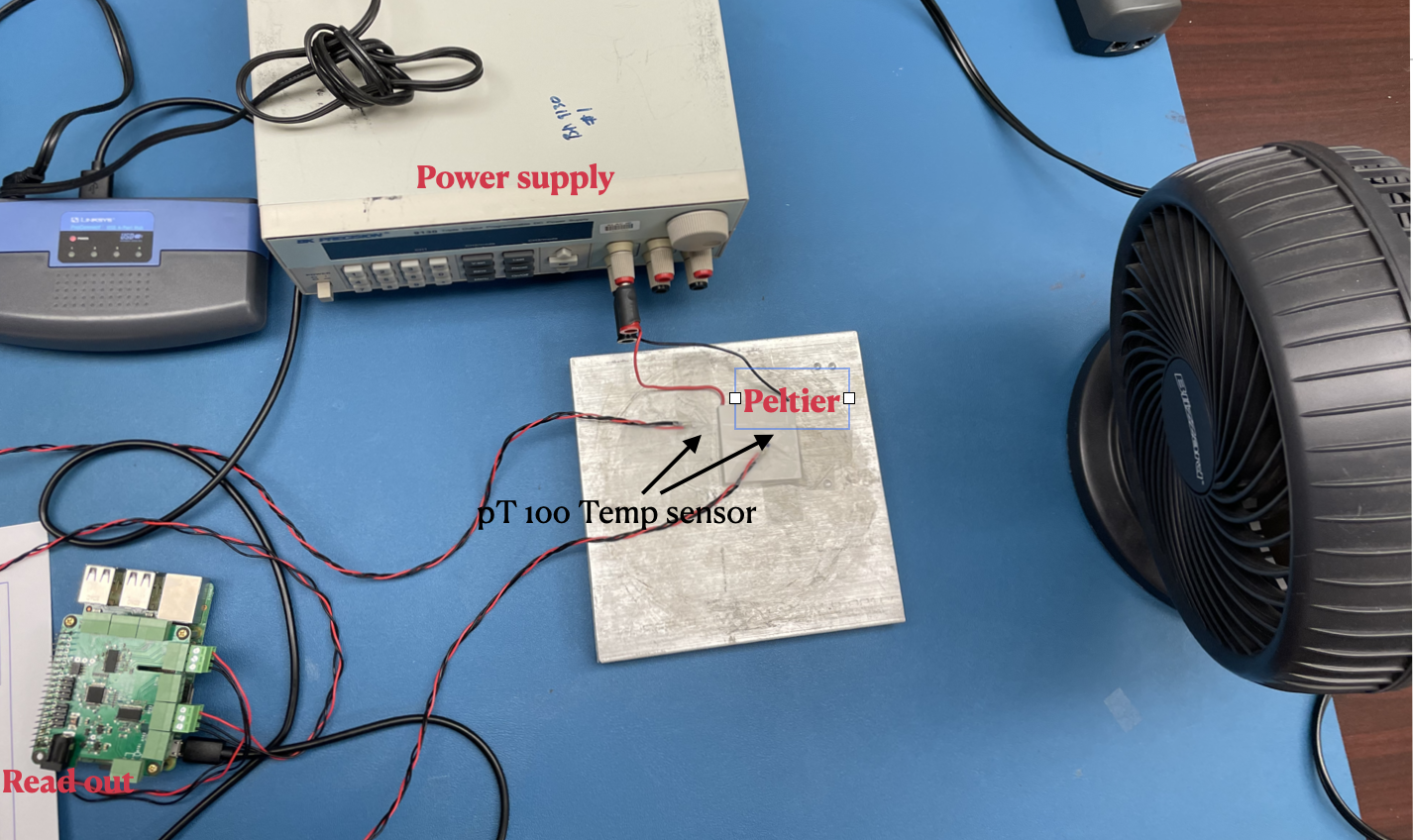

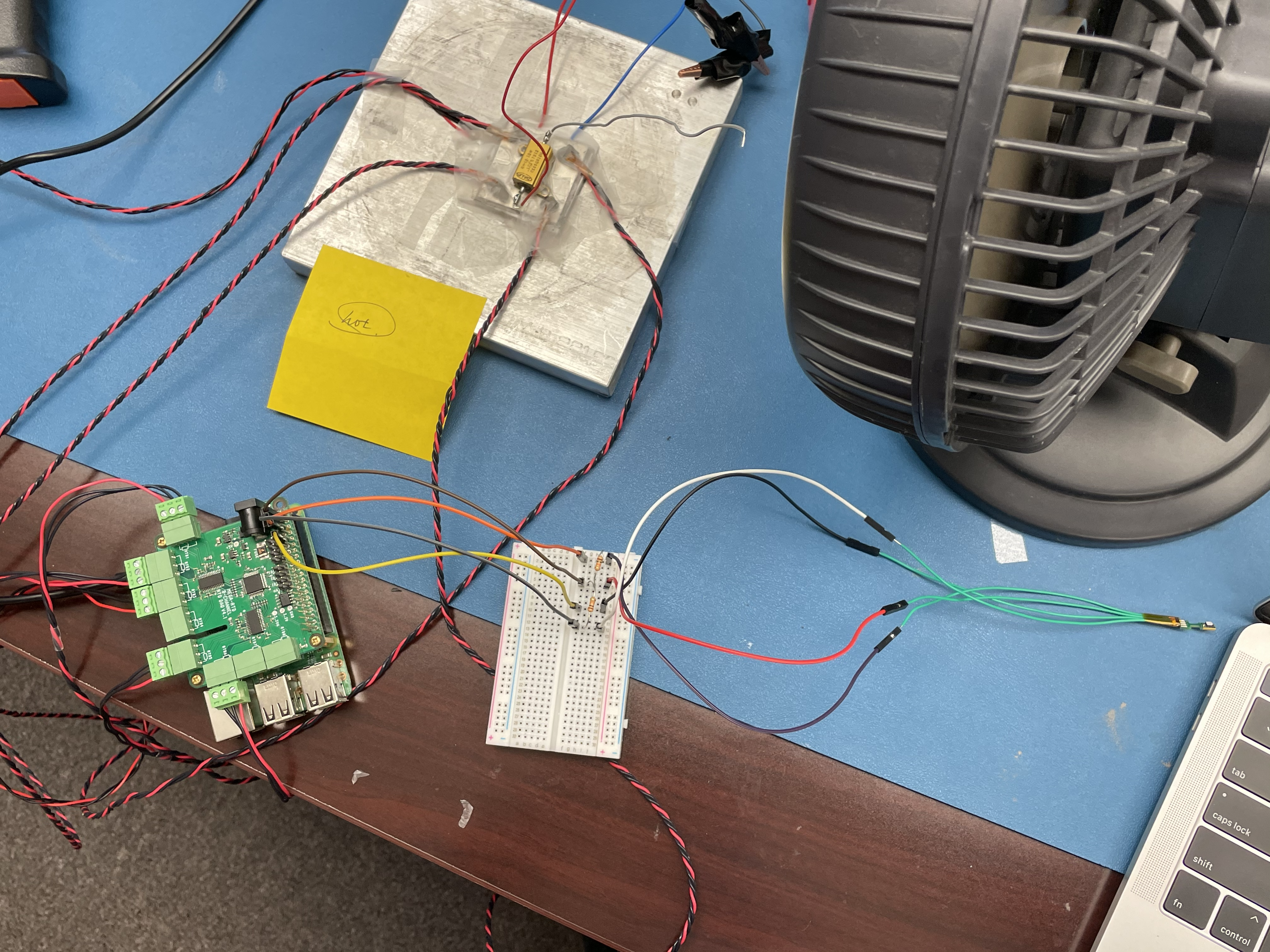

Setup for preliminary cooling test

Monitoring unit and Sensor

- Monitoring settingcooling unit: from Marco

- 2 moisture sensor (SHT85 and the DHT22) [sensor interface using I2C]

- 4 RTD

Temperature sensor

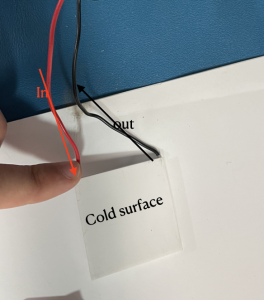

Temperature sensor: pT100

Humidity Sensor

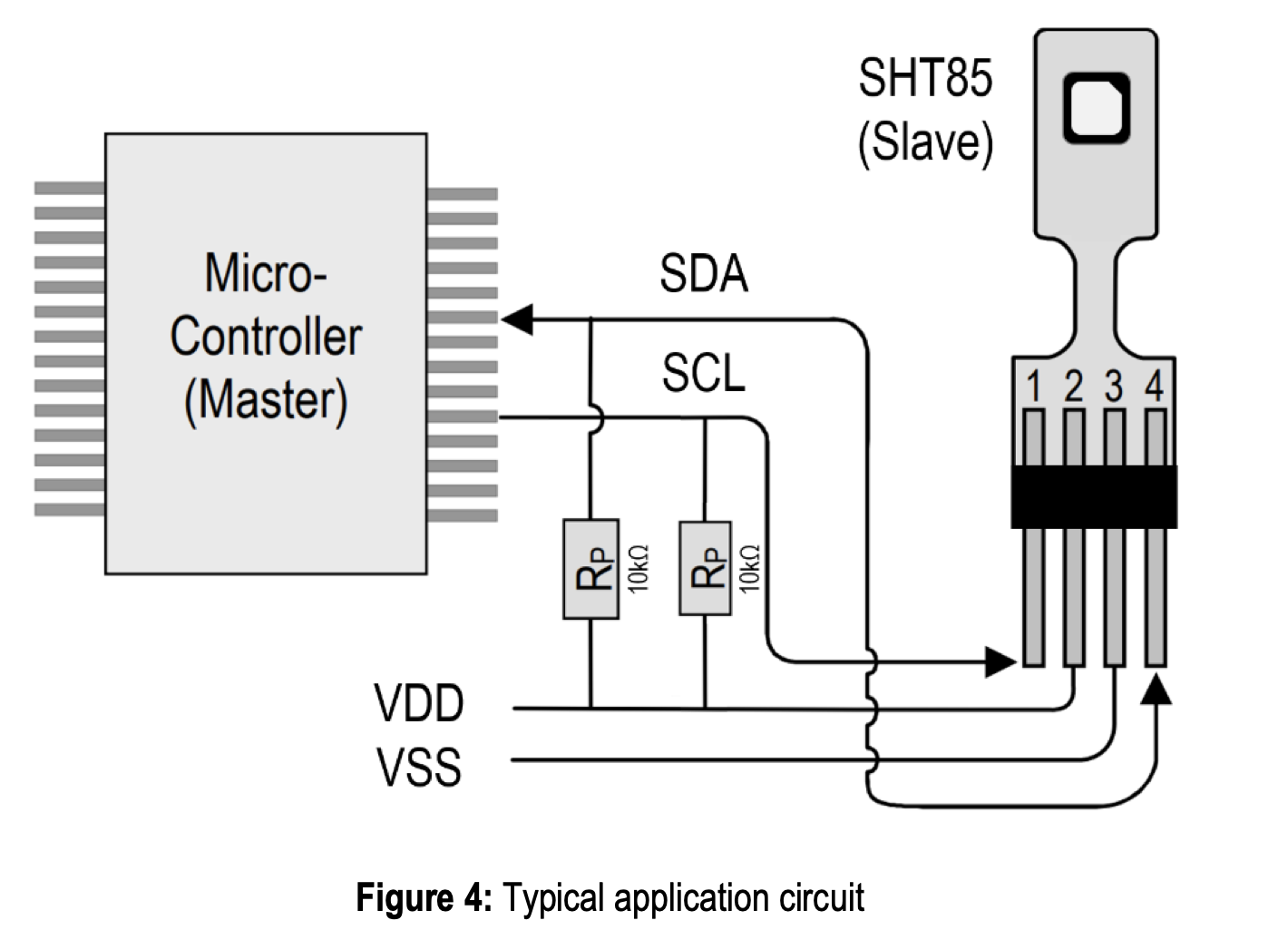

Setting up SHT85

Connecting SHT85 to raspberry pi:

Setup:

PI to SHT85 (datasheet)

pin 1 3.3V. to 2 VDD

pin 3 SDA to 4 SDA Serial data

pin 5 SCL to 1 SCL Serial clock

pin 9: ground to 3 VSS Ground

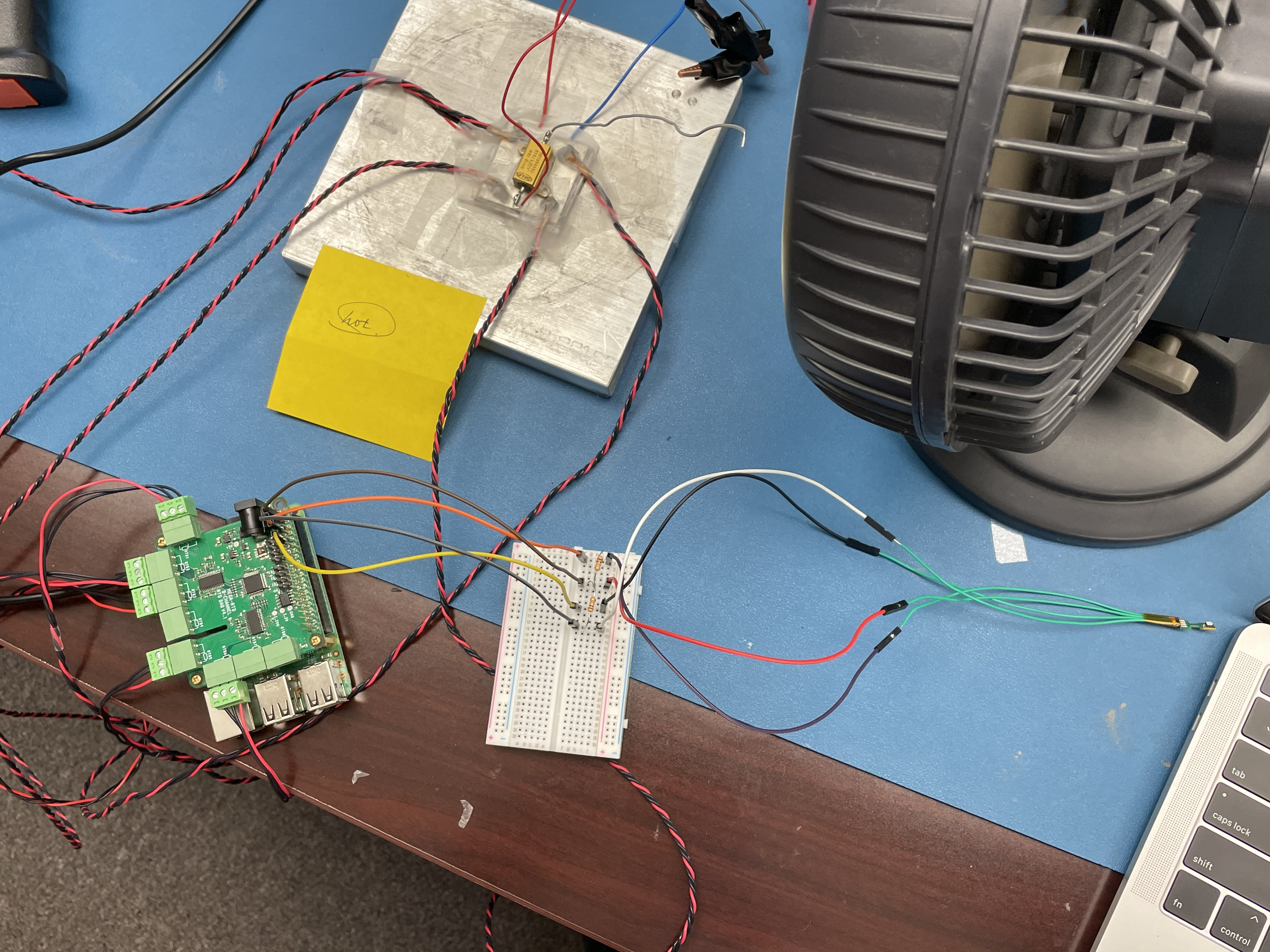

Monitoring

Readout: RTD Data Acquisition Stackable Card for Raspberry Pi with Raspberry Pi

Firmware to control: https://github.com/SequentMicrosystems/rtd-rpi

For SHT85: https://github.com/jothanna/sht85/tree/master/sht85

connecting to the raspberry pi:

- connecting to the rddev111

- ssh pi@192.168.4.122

- password: slac-dcs-cooling

Readout RTD database:http://atlascr.slac.stanford.edu:3000/d/AhqDEQ_Mk/dcs-cooling-tests?orgId=1&from=1619033502000&to=now&refresh=1m

(login atlas/atlas)

Interlock

- Overheating = the chiller fails and the PS keep running

- temperature on the cold plate

- Condensation = Dry air fails, moisture condense and destroys the device

- dew point < air temperature

- module temperature drop ←55C

- communication => fail safe

...

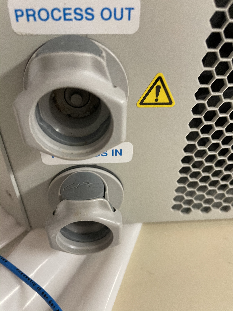

Chiller

| Connector | Connection to the filter |

|---|---|

Thermo Cube: Chiller manual

* CPC Quick disconnects are attached with chiller, need some coupling insert to connect to our tube (ID ~8mm/ OD ~11mm)

* options we have to are in this link (but seem no 1/4 in option)

Chiller setup with filter:

Peltier TE-127-1.0-2.5:

Empty load step up

Power supply: bk precision power supply 9130

Peltier: Peltier TE-127-1.0-2.5

Temperature sensor: pT100

Readout: RTD Data Acquisition Stackable Card for Raspberry Pi with Raspberry Pi

Firmware to control: https://github.com/SequentMicrosystems/rtd-rpi

connecting to the raspberry pi:

- connecting to the rddev111

- ssh pi@192.168.4.122

- password: slac-dcs-cooling

Readout RTD database:http://atlascr.slac.stanford.edu:3000/d/AhqDEQ_Mk/dcs-cooling-tests?orgId=1&from=1619033502000&to=now&refresh=1m

(login atlas/atlas)

Setting up SHT85

Connecting SHT85 to raspberry pi:

PI to SHT85 (datasheet)

pin 1 3.3V. to 2 VDD

pin 3 SDA to 4 SDA Serial data

pin 5 SCL to 1 SCL Serial clock

pin 9: ground to 3 VSS Ground

Coolant

from Su Dong:

There may be some additional piping volume within chiller besides the 300ml tank. It may sufficiently safe if we get two 700ml bottles of the recommended coolant by ThermoCube: Koolance 702 (27% propylene glyco + water mix): https://koolance.com/liq-702-liquid-coolant-bottle-high-performance-700ml-blue. Propylene glyco is a nicer substance (used as food additive in some cases) than the more commonly used ethylene glyco as an alternative antifreeze.

The exact model of the ThermoCube we are working with is 10-400-3G20-1-CP2-R2-LT-AR which I think means: 400W capacity, >3 lpm @ 30 psig magnetic drive gear pump, with adustable flow setting for 2 lpm, 3/8" CPC shutoff valve, RS232 interface, low temp op (<5 deg C) and auto restart software.

This might an old model which doesn’t say what type of cold plate it is. Stainless would have carried a tag ’S” some where so this may be old style anodized AL PCW plate ? Koolance claims to be friendly with both Al and SS.

Peltier

- Peltier: 4 sets to be tested:

- 2 layer peltier (recommend): Laird 108161050003 (53W) and Laird 387004685 (125W)

- 1 Layer peltier: Sheetak SKCM-240-11-T100-NS-TF00-ALO (75W)

- 1 Layer peltier: HP-199-1.4-0.8 (120W)

- 1 Layer peltier: HP-199-1.4-1.15 (175W)

Peltier TE-127-1.0-2.5:

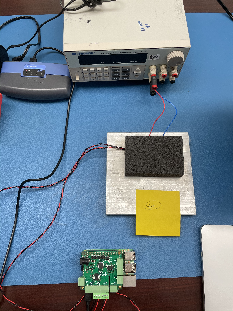

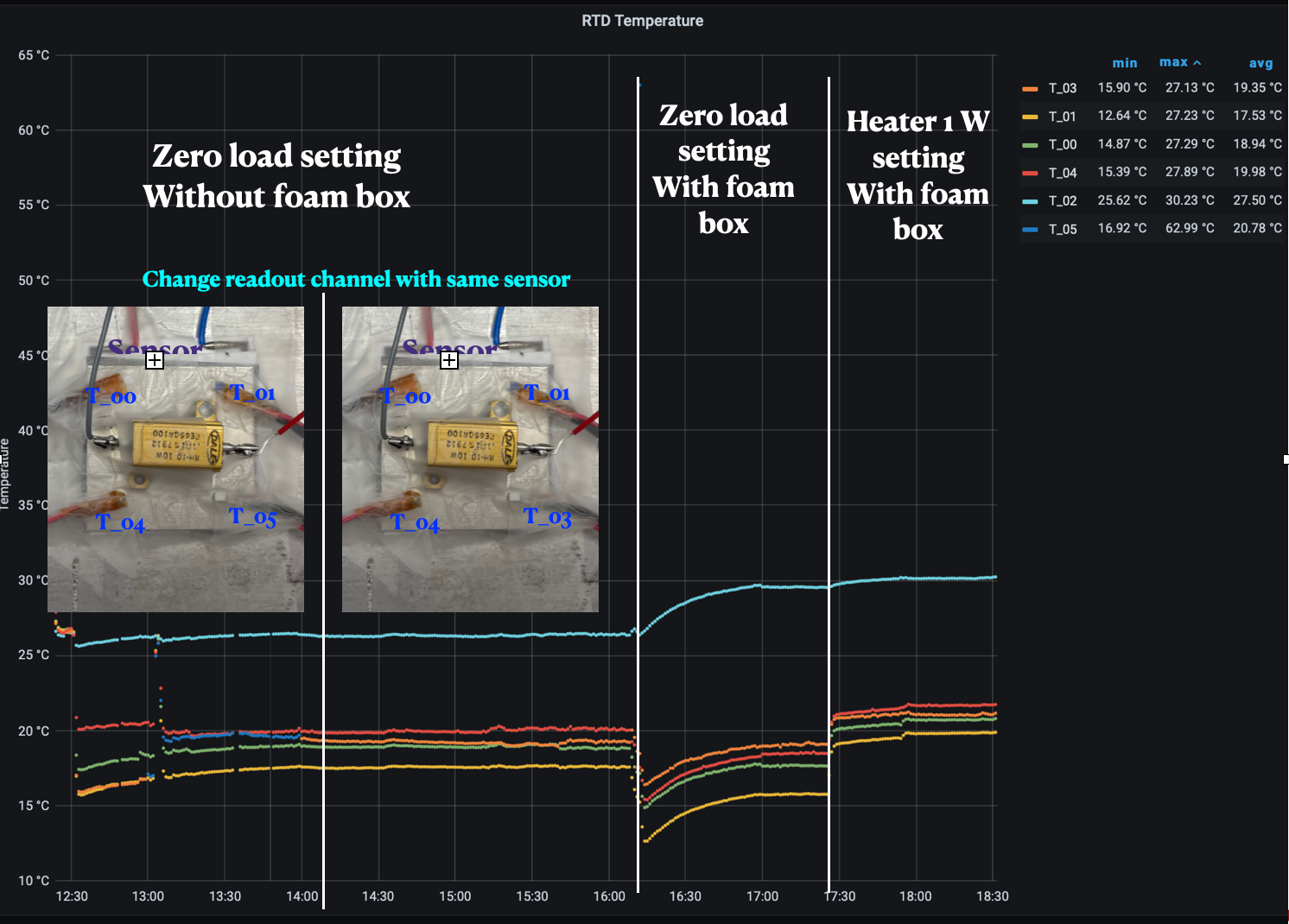

Preliminary Setup and Test Result

Empty load step up | With Heater | with foam box |

|---|---|---|

Results

- Check the Temperature distribution on the Peltier, temperature distribution is not flat on the cold side of Peltier while running the Peltier

- foam box can help isolate the Peltier system and increase the temperature difference between hot side and cold side

- running load will increase the temperature on the cold side