...

7. Hot plate (to achieve 220C)

8. Protective equipment

Cobar core solder 63/37 type with flux core

...

Solder-Wick by Chemtroncs (Left). Hex-Wick by Hexacon Electric Co.

List of Steps

(use photos for reference - NOTE: the "single" and "quad" modules are used interchangeably in the photos)

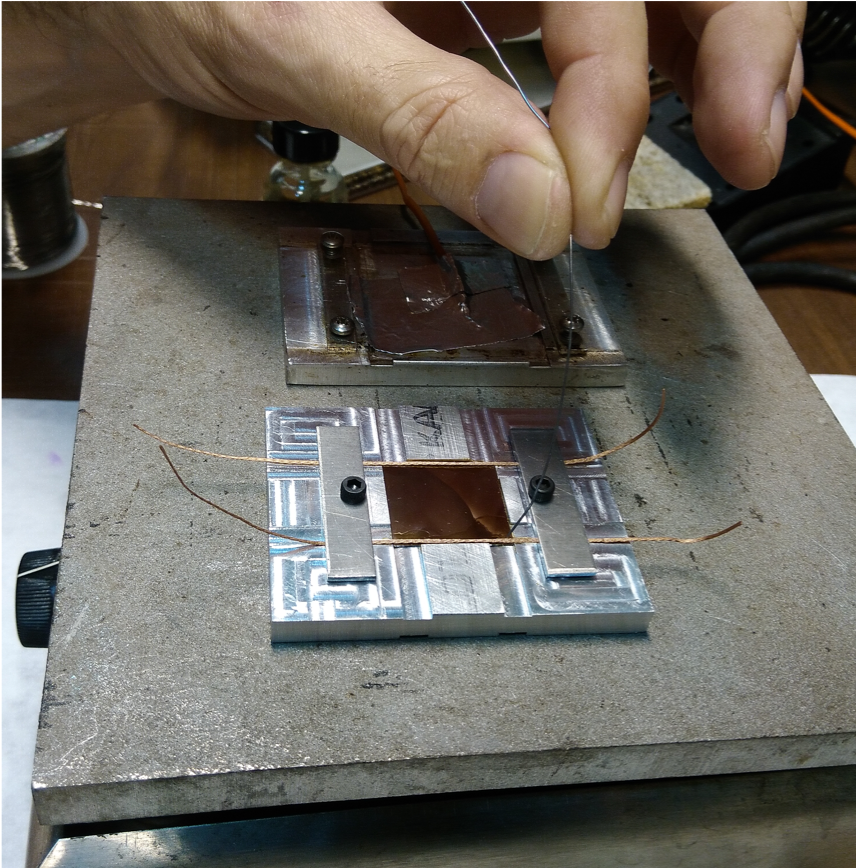

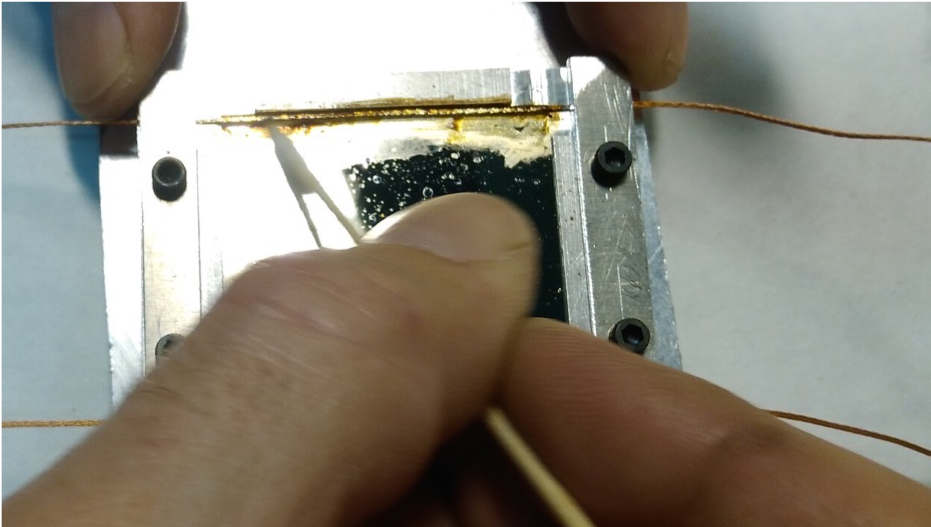

- Place heaters in the fixtures

- Align 2 solder wicks across the edge of the heater and hold them in place with the aluminum bar

- Fasten the aluminum bar down with the screw to keep the wick from moving

...

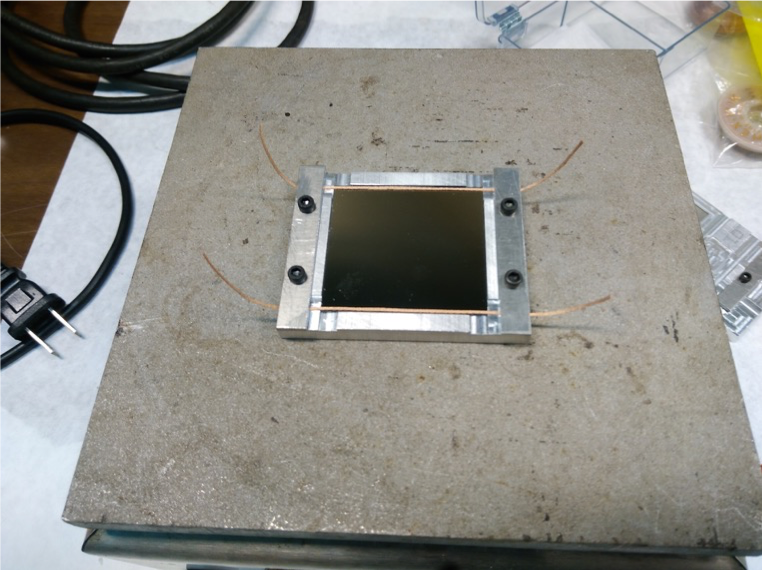

- Once in the heater is assembled into the fixture place it on top of the hot plate

- Bring the hot plate up to 220 C

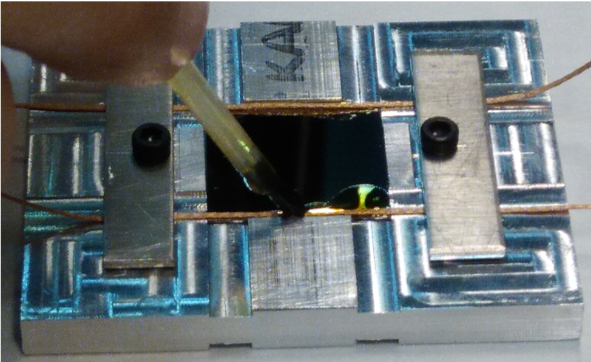

- When the aluminum fixture reaches temperature of the hotplate: apply flux to the area between the solder wick and the heater

...

- Try to keep the flux contained to the location where the solder will go ("Don't get the flux anywhere you don't want solder")

- Apply the solder to the area between the solder wick and the heater. (the solder wick should be 0.03 inches in diameter, the solder wire should be between 0.012 and 0.02 inches in diameter

- Once the solder is applied, turn off the hot plate and remove the fixture with the heater

- Wear protective gear!! Be careful: do not to touch the hot plate!!

- Let the solder cool

- Once the solder is cool clean the flux away with alcohol and a wooden q-tip stick

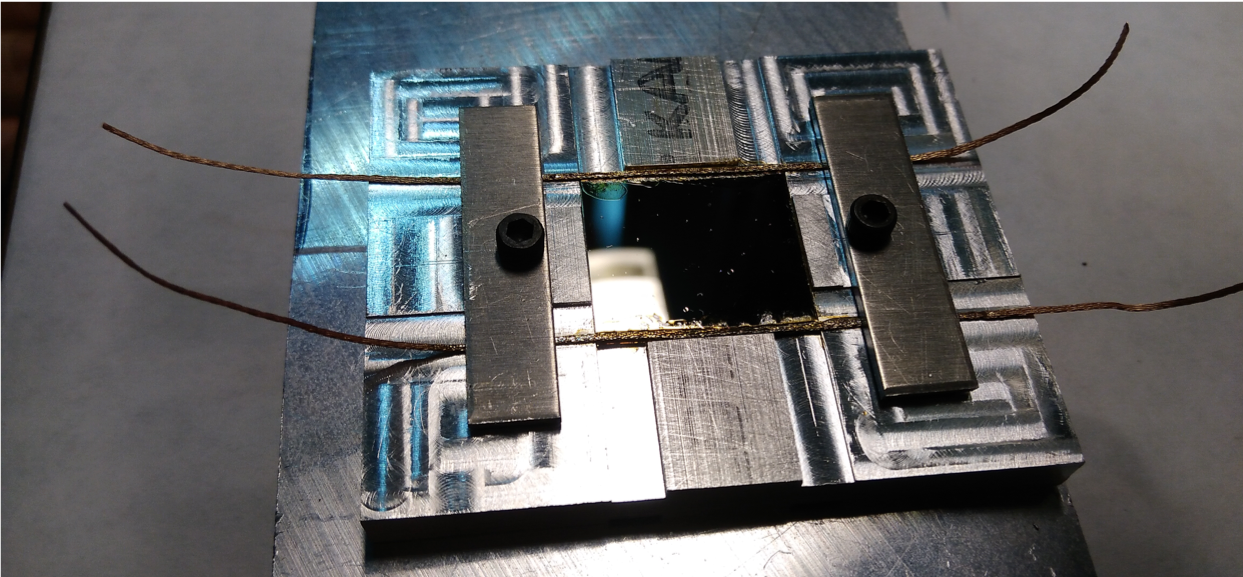

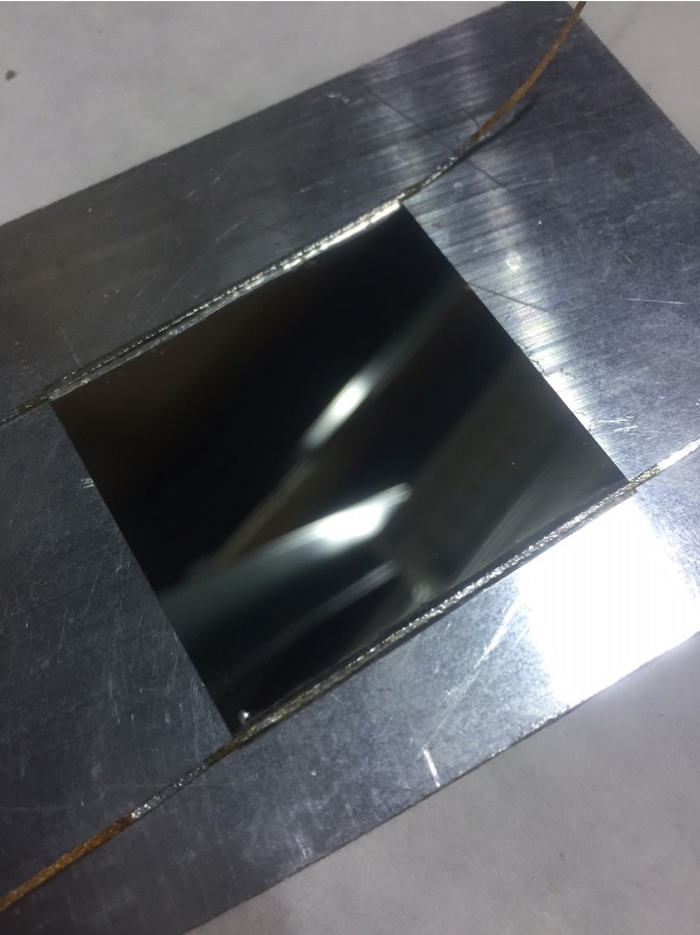

- Once complete the heater with the soldered on wicks will look like this: