Page History

...

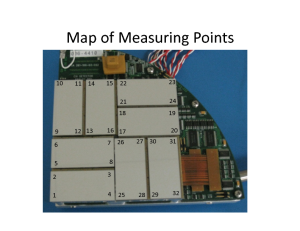

Optical measurement is maintained by Chris Kenney. Detector or its quad is installed on microscope table and 3-d coordinates of all 2x1 sensor corners are measured with precision about 8um (RMS) in x-y plane. All corners in the measurement are numerated in arbitrary order. This order does not coincide with numeration of 2x1 in DAQ, as shown on plots below. It is expected that numeration order should be the same for different measurements. This procedure depends on CSPAD construction;

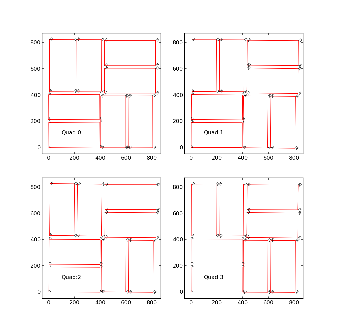

- For CSPAD with moving movable quads (i.e. for CXI) optical measurement is done separately for each quad. The numeration of corners is shown in the plot:

The same plots in PDF format: CSPAD quad metrology and CSPAD pixel layout in quads.

See also: Description of CSPAD layout from DAQ

...

- Metrology in XLSX

- Metrology in TXT

Python script converts this table to the table with standard numeration for quads: - Metrology in standard TXT

QC procedure

Then, text table with "standard" numeration of points for quads is feed to another python script which provides the quality check of optical measurement and evaluates the alignment parameters for quads.

At first step this script changes the numeration of points adopted in optical measurement to numeration of 2x1 used in DAQ.

Quality Check Procedure

For quality check of optical measurement For quality chech we calculate

S1 - 1st short side length of 2x1

S2 - 2nd short side length of 2x1

L1 - 1st long side length of 2x1

L2 - 2nd long side length of 2x1

D1 - 1st diagonal of 2x1 between corners 1 and 3

D2 - 2nd diagonal of 2x1 between corners 2 and 4

dS and dL are the deviations of the 1st and 2nd corner along the short and long sides, respectively. The sign of all dS are chosen in order to provide correct sign for the tilt angle (the same direction for all 2x1 sensors).

<dS/L> - the tilt angle of 2x1 averaged over two sides in radians.

angle(deg) - the same angle in degrees.

dD = D1 - D2

d(dS) = dS1 - dS2

d(dL) = dL1 - dL2

...