Page History

...

Optical measurement is maintained by Chris Kenney.

This procedure depends on CSPAD constructionDetector or its quad is installed on microscope table and 3-d coordinates of all 2x1 sensor corners are measured with precision about 8um (RMS) in x-y plane. All corners in the measurement are numerated in arbitrary order. It is expected that numeration order should be the same for different measurements. Point-by-point measurements are accumulated in the xlsx format table. This procedure depends on CSPAD construction;

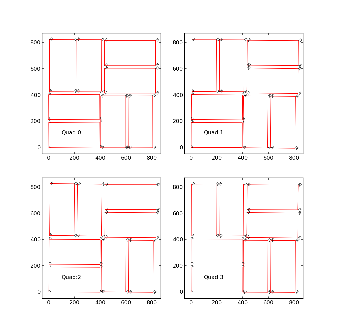

- For CSPAD with moving quads (i.e. for CXI) optical measurement is done separately for each quad. The numeration of corners is shown in the plot:

For each quad measurement is started from the point #1 which in assembled detector is closest to the beam. The 1-st point (x,y,z) coordinates are re-set to (0,0,0) in the beginning of measurements. At the end, it is checked that the 1-st point coordinates are reproduced within precision of measurement. - For CSPad with

...

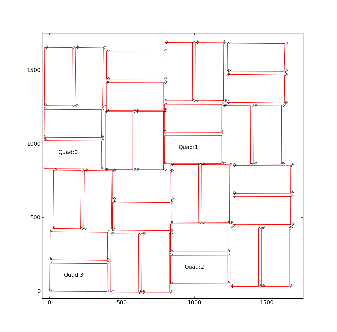

- fixed quad geometry (i.e. for XPP) optical measurement is done for entire detector. The 1st corner of 3-rd quad (x,y,z) coordinates are re-set to (0,0,0) in the beginning of measurements for the, as shown in the plot

Corner coordinates are measured

For CSPad with fixed quads (for XPP) measurement is done for entire detector:

Chris produces a table of corner coordinates in um (micrometers) and are saved in the xlsx format :

which table.

Then, xlsx format table is converted by hands to text format in order to feed the python script for quality check and getting calibration parameters for 2x1 center coordinates and tilt angles.

Example of tables for CXI:

Example of tables for XPP:

...