Goal of this procedure: Enter oven mode and reach desired oven profile

Instructions: To keep track of changes to the procedure - copy this page, date it, and add execution notes in red. Remember to save changes.

Table of Contents:

Table of Contents

NOTE - WORK IN PROGRESS!

Procedure

Checkout and setup

| Procedure | Execution notes | |

|---|---|---|

| 1 | Record goal density and helium buffer pressure | |

2 | Set 10 Torr gauge set points to plus and minus 1 Torr of desired pressure

| |

| 3 | Set the 1000 Torr gauge setpoint to 20 Torr | |

4 | Confirm helium gas bottle is connected to fill line 1, regulator set to 5-10 psig | |

| 5 | If using DPS, confirm it is operating nominally. |

519px600

Procedure for oven turn on

| Procedure | Execution notes | |

|---|---|---|

| 1 | Verify vacuum conditions approximately 1e-6 Torr or better - Record pressure | |

2 | Zero the 10 and 1000 Torr gauges | |

| Purge fill line by running a small amount of He through the fill valve and then stopping and pumping out the IP - Record final pressure | ||

| 3 | Set EPS EXPERT Mode to be “ON” by turning the interlock key in the EPS box in Rack 20-27 in the gallery.

| |

| 4 | Unlock oven gate valves (switch to CAMAC mode) | |

| 5 | Open oven gate valves 3183 and 3187. (there might be a small amount of helium between the valves). Continue pump down to 1e-6 Torr - Record pressure | |

| 6 | Close angle valve VV3201 isolating the plasma beamline from the plasma turbo | |

| 7 | Check Beryllium window valve VV3208 is closed- close if not! | |

| 8 | Set up strip-tool of pressure in the plasma oven:

| |

| 9 | Fill IP with He to goal IP pressure. If using DPS then follow: How to perform a static fill with DPS | |

| 10 | Hit EPS Reset to clear the low pressure fault | |

| 11 | Set EPS EXPERT Mode to be “OFF” by turning the interlock key in the EPS box in Rack 20-27 in the gallery. (Note: EXPERT mode is “OFF” if the LED light is OFF and EXPERT mode is “ON” if the red light is ON) . | |

| 12 | While at the racks, Turn valve control for the beryllium window valve to local only and remove key. Note: the EPICS controls for this valve are also password protected so this will be very well configuration controlled. | |

| 13 | Back at the computer, perform an EPS reset (this is needed to enable the heater) | |

| 14 | Set up striptool of oven thermocouples plus the thermocouples on the bypass line, cooling water jackets, base-plate and air.

| |

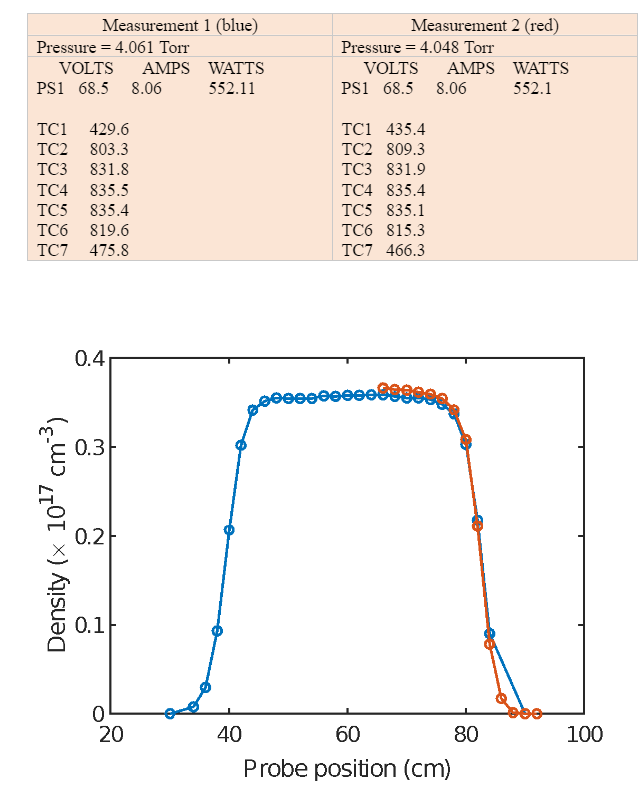

| 15 | Raise heater power (Upstream Heater PS1) slowly (~ 100 Watts per hour) while monitoring the oven pressure and temperature until desired operating conditions and are reached at approximately 550 W (table and plot in next column)- we probably need 10% higher than UCLA to match the profile so don’t be scared to push it up a bit to 600 W.

| Notes from March 2022:

|

| 16 | Check that the oven thermocouple readings are nearly the same as those shown on the profile plot. Ambient conditions may vary, so fine tune the pressure and heater power as needed.

|

Procedure for oven shut down

9 hours turning down by hand- 11 hours until valves can be closed

| Procedure | Execution notes | |

|---|---|---|

| 1 | ||

2 | ||

| 3 | ||

4 | ||

| 5 |

Figures:

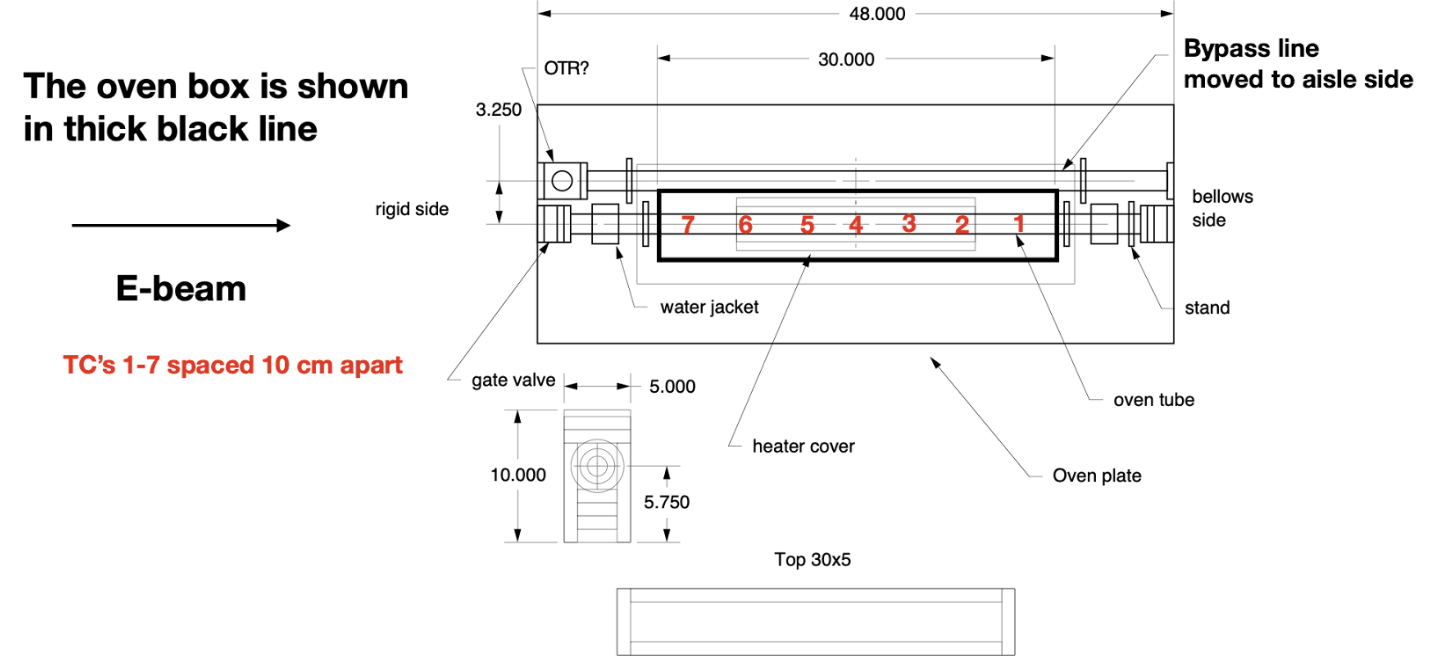

Li oven sketch with TC locations

Li density profiles

From: Summary of FACET II lithium oven measurements - June 3, 2021

More profiles available in doc (3 Torr, 4 Torr, 6 Torr, 8 Torr