Goal of this procedure: Enter oven mode and reach desired oven profile

Instructions: To keep track of changes to the procedure - copy this page, date it, and add execution notes in red. Remember to save changes.

Table of Contents:

Link to elog summary:

enter here

Procedure

Update 4/8/2024 for simplified

Checkout and setup - Perform these steps several hours before opening the oven valves

| Procedure | Execution notes | |

|---|---|---|

| 1 | Record goal density and helium buffer pressure | |

2 | Set 10 Torr gauge set points to plus and minus 1 Torr of desired pressure

| |

| 3 | Set the 1000 Torr gauge setpoint to 30 Torr | |

| 4 | If using DPS, confirm it is operating nominally and record the starting IP pressure (VGCC 3259) | |

4 | Confirm helium gas bottle is connected to fill line #1, regulator set to 5-10 psig. Record gas type, starting bottle pressure, and regulator pressure | |

| 5 | Confirm that the fill line #2 is closed, and that the IOTA controller in rack FKG20-22 is turned off. | |

| 6 | Zero the 10 and 1000 Torr gauges | |

| 7 | Fill IP with He to goal IP pressure using: Note - the US2/3/4 gauges will trip off shortly after starting the static fill. You will need to restart the gauges (turn cathode HV On), then reset the valve interlocks, reopen the beamline valves, then continue with the static fill. This will happen once every time you pass the threshold of ~1e-3 Torr on US1. |

Procedure for oven turn on

| Procedure | Execution notes | |

|---|---|---|

| 1 | Allow gas to flow for a minimum of 30 minutes. Stop the flow from the mass flow controller | |

| 2 | Ensure that gauges US1, US2, US3 and DS1 CC are bypassed. | |

| 3 | Confirm the 10 and 1000 Torr setpoints are set appropriately for the desired oven pressure | |

| 4 | Confirm the Beryllium window valve VV3208 is closed - close it if not! | |

| 5 | Set up strip-tool of pressure in the plasma oven:

Set up striptool of oven thermocouples plus the thermocouples on the bypass line, cooling water jackets, base-plate and air.

| |

| 6 | Head out the FKG20 racks | |

| 7 | Set EPS EXPERT Mode to be “ON” by turning the interlock key in the EPS box in FKG20-27 in the gallery.

| |

| 8 | Unlock oven gate valves: Use the key to switch the valve controller labeled VV3183 VV3187 in rack FKG20-22 to "CAMAC" mode | |

| 9 | Lock the Be window valve to be inserted: Use the same key to switch the valve controller labeled VV3208 to "LOCAL ONLY" and remove the key. Note: the EPICS controls for this valve is also password protected so this will be very well configuration controlled. | |

| 10 | Open oven gate valves 3183 and 3187. (there might be a small amount of helium between the valves). If the interlock is faulted then perform a valve interlock reset. | |

| 11 | Turn on the oven heater power supply. Open the "Genesys Expert..." panel and select "PS On" to ON | |

| 12 | Restart the gas flow from the MFC and fill back to the goal pressure. Note - the beamline valve interlock will likely trip again. If it does, restart the gauges and continue as described above. | |

| 13 | When you are at the goal pressure - Hit EPS Reset to clear the low pressure fault | |

| 14 | Set EPS EXPERT Mode to be “OFF” by turning the interlock key in the EPS box in Rack 20-27 in the gallery. (Note: EXPERT mode is “OFF” if the LED light is OFF and EXPERT mode is “ON” if the red light is ON) . You are now done at the racks. | |

| 15 | Perform another EPS reset (this is needed to enable the heater) | |

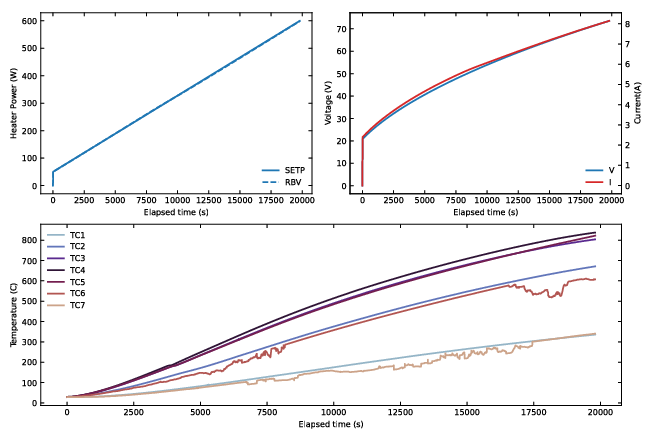

| 16 | Raise heater power slowly (~ 100 Watts per hour) while monitoring the oven pressure and temperature until desired operating conditions and are reached. This can done manually by entering the voltage setpoint on the E300 panel, Or - use the automated tool: screen -S ovenScreen python $TOOLS/pydm/display/user-facet/tools/ovenStartUp.py [power] where [power] == target power To detach the screen: crtl-a then crtl-d To reattach the screen: screen -d -r ovenScreen Progress is logged in ovenStartUp.log During the oven heat up:

| Notes from June 2023:

|

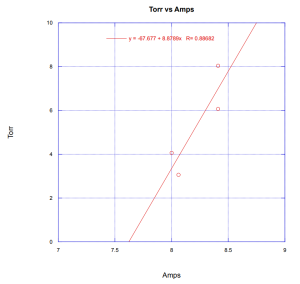

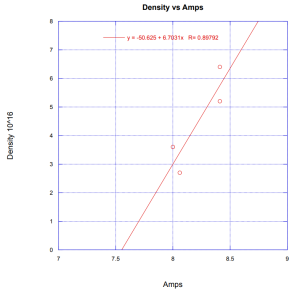

| 17 | Fine tune the heater power to reach the desired oven profile. This plot shows the desired heater current vs. pressure:

Note: Reducing the helium gas pressure in a hot oven could cause loss of lithium! Reduce the heater power to achieve the desired oven temperature then slowly reduce the helium pressure. Slowly raising the buffer gas pressure will not harm the oven. |

Procedure for oven shut down

9 hours turning down by hand- 11 hours until valves can be closed

| Procedure | Execution notes | |

|---|---|---|

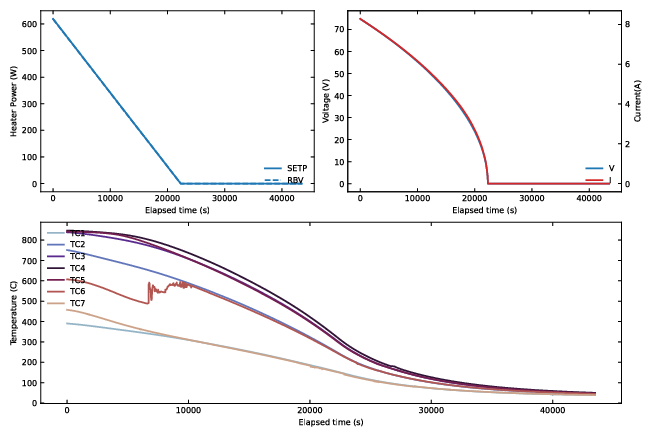

| 1 | Turn off heater supply slowly to reduce thermal stress to the oven tube and wick. Do this either by hand, or using the automated tool (~ 100 Watts per hour) screen -S ovenScreen python $TOOLS/pydm/display/user-facet/tools/ovenShutdown.py To detach the screen: crtl-a then crtl-d To reattach the screen: screen -d -r ovenScreen | Previous notes

|

2 | After the heater power is turned down to 0, wait until oven thermocouples indicate the oven is near room temperature (less than 50°C). Lithium is liquid at 180°C. Takes about 11 hours to reduce to 50C | |

| 3 | Write down the buffer pressure for the record in the facet elog | |

4 | Close oven gate valves 3183 and 3187. Turn the key to “CLOSE VALVE” in the PLC valve controller in rack FKG20-22 and remove the key. This will disable the valves from opening. Set the Be window valve 3208 back to CAMAC. | |

| 5 | Drain all helium gas and open valves to restore pumping. If using DPS then follow: How to perform a static fill with DPS | |

| 6 | Open the Be window valve, remove bypasses, and reset gas types on the gauges to nitrogen. |

Emergency shut down procedure

If possible the oven should be cooled slowly using the above procedure to reduce thermal stresses on the oven. But in an emergency situation the oven may be put into a safe-mode to prevent loss of lithium using the following procedure. Note that depending on the situation, some of these steps are automatically taken by the EPS.

| Procedure | Execution notes | |

|---|---|---|

| 1 | Close oven gate valves 3183 and 3187. If there is an EPS fault then this happens automatically. | |

2 | Turn off the oven heater power. If there is an EPS fault then this happens automatically. | |

| 3 | Secure the helium gas source – either drain the IP or ensure DPS is operating in the nominal static fill state: How to perform a static fill with DPS | |

4 | Log the details of the fault and shutdown: type of fault, reason if known, IP pressure, oven temp, and any other relevant information. | |

| 5 | Turn the key to “CLOSE VALVE” in the PLC valve controller in rack FKG20-22 and remove the key. This will disable the oven gate valves from opening. | |

| 6 | Do not attempt to restart the oven until you investigate, find, and fix the source of the failure. |

Figures:

Useful material

How to perform a static fill with DPS

TDK-Lamdba GEN100-15 oven heater power supply manual

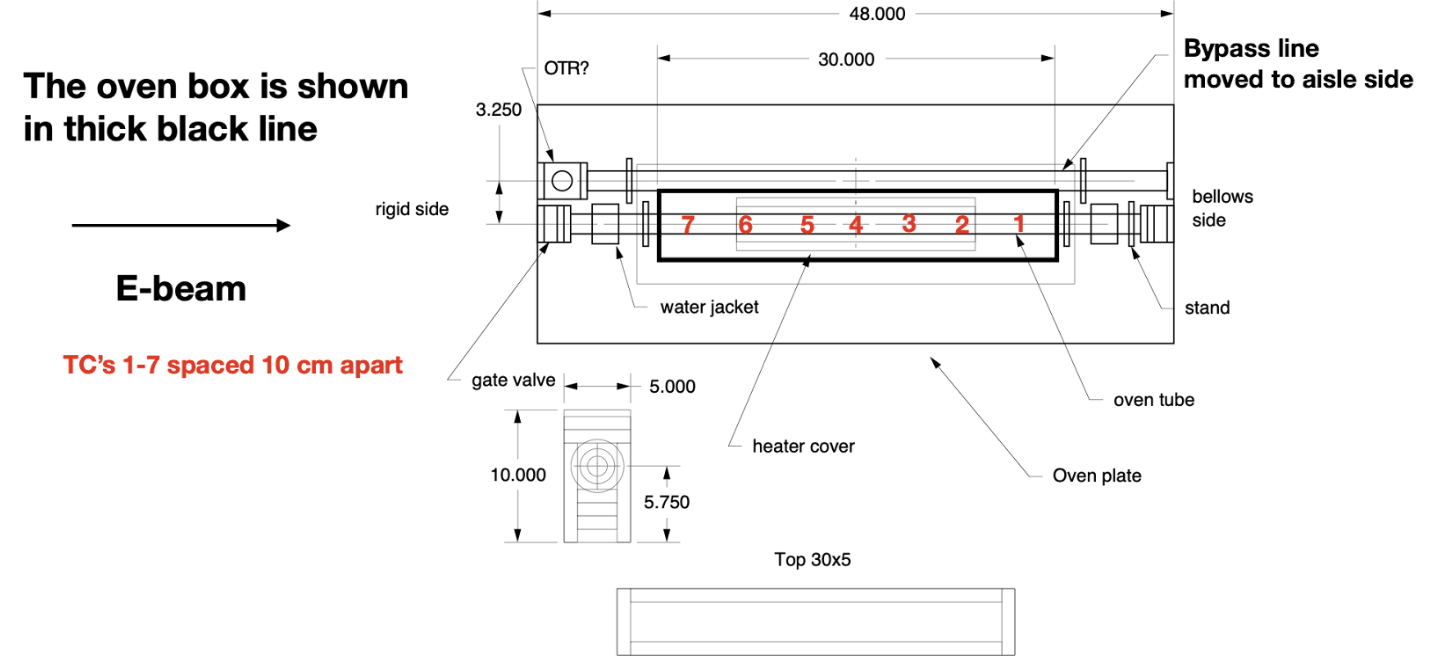

Li oven sketch with TC locations

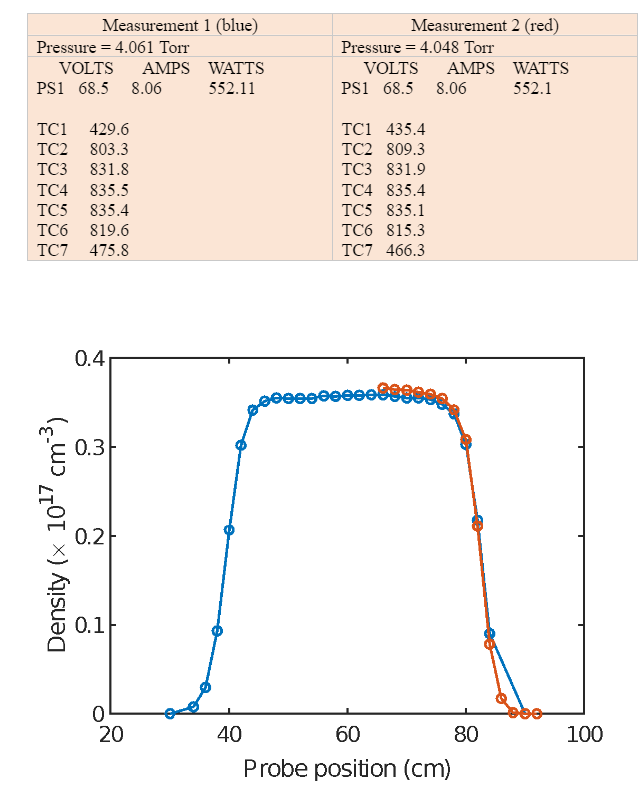

Li density profiles

From: Summary of FACET II lithium oven measurements - June 3, 2021

More profiles available in doc (3 Torr, 4 Torr, 6 Torr, 8 Torr

From Ken 4/8/2024:

- At pressures less than 3 Torr, stay below ~450C on TC 1 and 7.

Temperatures from heat up (8 Torr)and shut down (from 5 Torr)