...

| Coolant connector (3/8" CPC) on unit #2 | Connection to the filter for unit #1 | Unit #1 with Swagelock QC4-316 joint for application insertion | Unit #1 view from above its filter |

|---|---|---|---|

|

Thermo Cube: Chiller manual

Tubing

- A) Application section (2*140cm): Our application tubing came with the CERN shipment is a Saint Gobain Tygon S3 E3603 NSF-51 with 8mm ID/11.5mm OD that fit well onto the cooling block thread nosebarb (ridge ID/OD=0.306"/0.363"=7.8/9.2mm). To avoid adapting metric-Imperial tubing, we also tried a 1/4" soft tubing and that seemed to just about being able to get on the cooling block barb OK although a bit tight so we would with very tight fit. Since we may never dissemble the cooling block after initial assembly, we opted to go with the 1/4" ID and 3/8" OD tubing so that the two ends can fit onto the Swagelock Swagelok Instrumentation quick connect ( QC6-316 (SS-QC6-D-600 / SS-QC6-B-600) with 3/8" fitting. Aiming for the same soft PVC Tygon chemical tubing as the original CERN part with ID/OD=1/4"/3/8" corresponds to McMaster-Carr #5155T26.

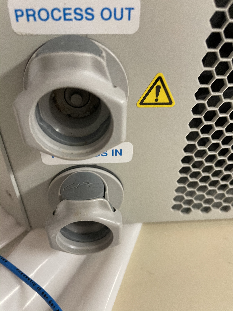

- B) Application joint to chiller Process In (30+15cm): Application joint is QC6-316 with 3/8" OD tube (SS-QC6-D-600 / SS-QC6-B-600 ) as for ~30cm then transition to a short (15cm) 1/2" tube A) with 3/8" OD tube (McMaster-Carr #5155T26) for ~30cm then transition (with McMaster-Carr #91355K32) to a short (~15cm) 3/8" ID tube (McMaster-Carr #5155T34) to fit onto the 3/8" hose barb from the HFC 12 series (rating only down to 0C ?) which can connect with the 3/8" CPC at chiller Process In.

- C) Application joint to filter (or Process Out) (30+15cm): similar piece like B), such that the hose barb end can plug directly into the chiller Process Out, or filter out.

- D) Filter: Not yet identified the exact part for the filter in the ThermoCube manual. Only the mounting bracket at McMaster is found. Also needs caution whether filter is compatible with <0C coolant. The filter output end should be fitted with the 3/8" NPT shutoff as those on the chiller unit. Filter inlet (fitting unknown) needs to transition to 1/2" tuber over the 3/8" hose barb to connect to the chiller Process Out.

- E) Jacket insulation: At least all thinner tubing section should have foam jacket insulation to allow running coolant <~0C.

...