...

4. Alcohol for cleaning the flux from the fixtures after the soldering. A wood toothpick and cotton swab is useful to rub off some of the remaining flux.

Also, rinse the remaining wick with alcohol as it contains dry flux and looks nicer when its it's cleaned off.

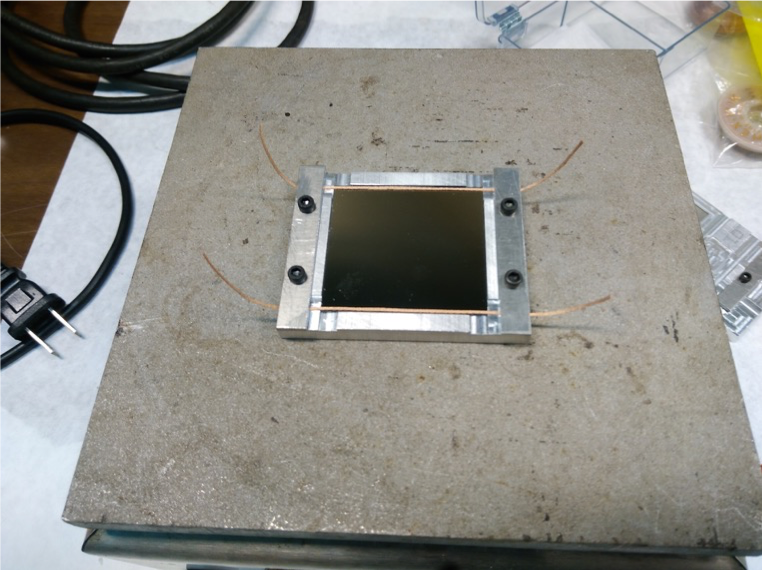

5. Heaters

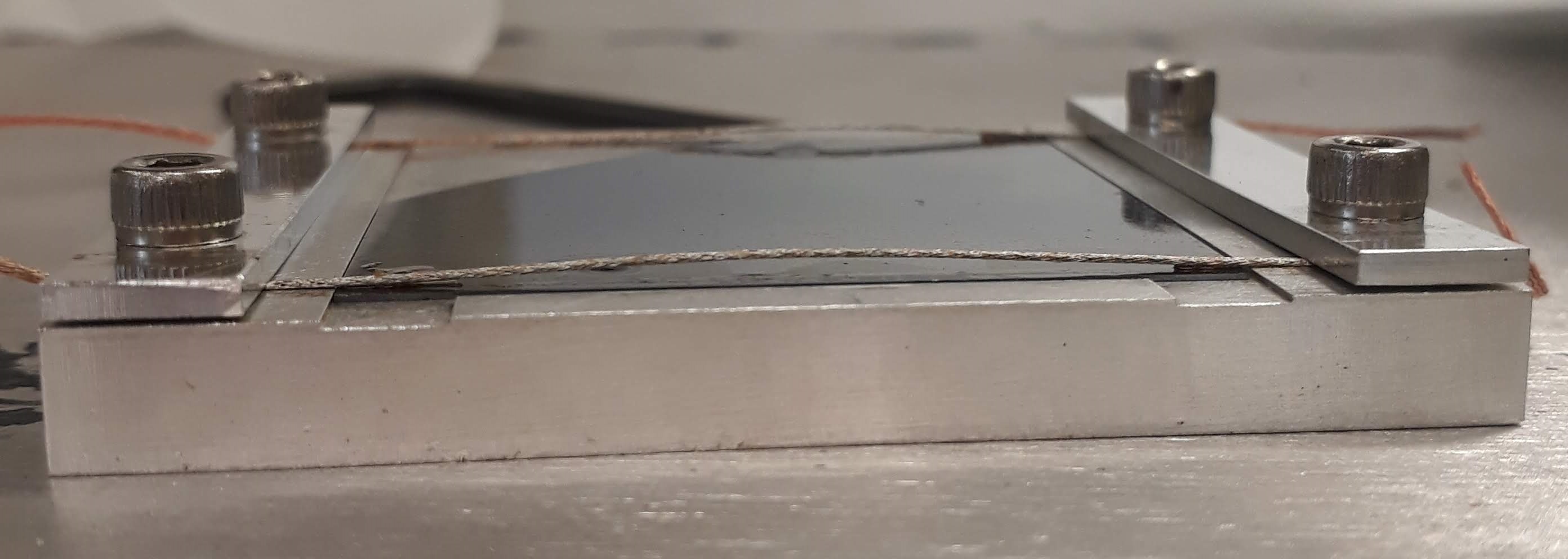

6. Fixture to hold heaters and fixtures

...

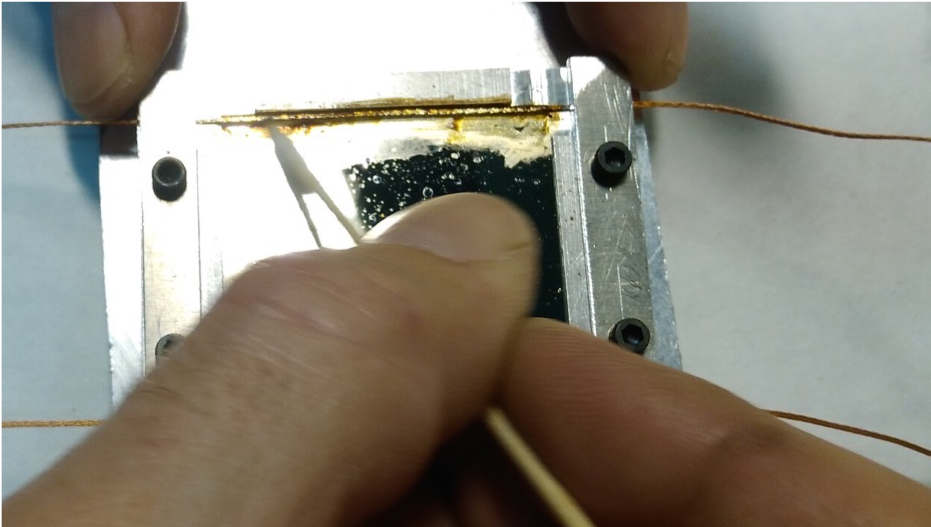

- Once in the heater is assembled into the fixture place it on top of the hot plate

- Bring the hot plate up to 220 C

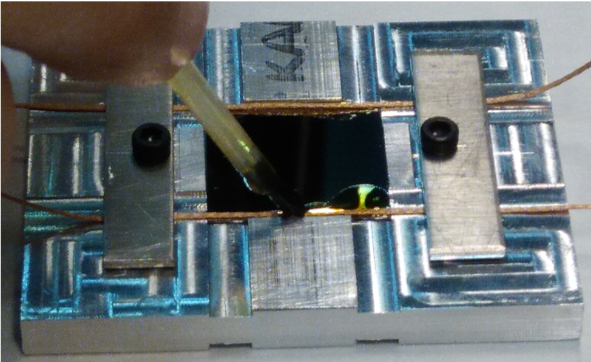

- When the aluminum fixture reaches the temperature of the hotplate: apply flux to the area between the solder wick and the heater

- Try to keep the flux contained to the location where the solder will go ("Don't get the flux anywhere you don't want solder")

- Apply the solder to the area between the solder wick and the heater. (the solder wick should be 0.03 inches in diameter, the solder wire should be between 0.012 and 0.02 inches in diameter

- Once the solder is applied, turn off the hot plate and remove the fixture with the heater

- Wear protective gear!! Be careful: do not to touch the hot plate!!

- Let the solder cool

- Once the solder is cool clean the flux away with alcohol and a wooden q-tip stick

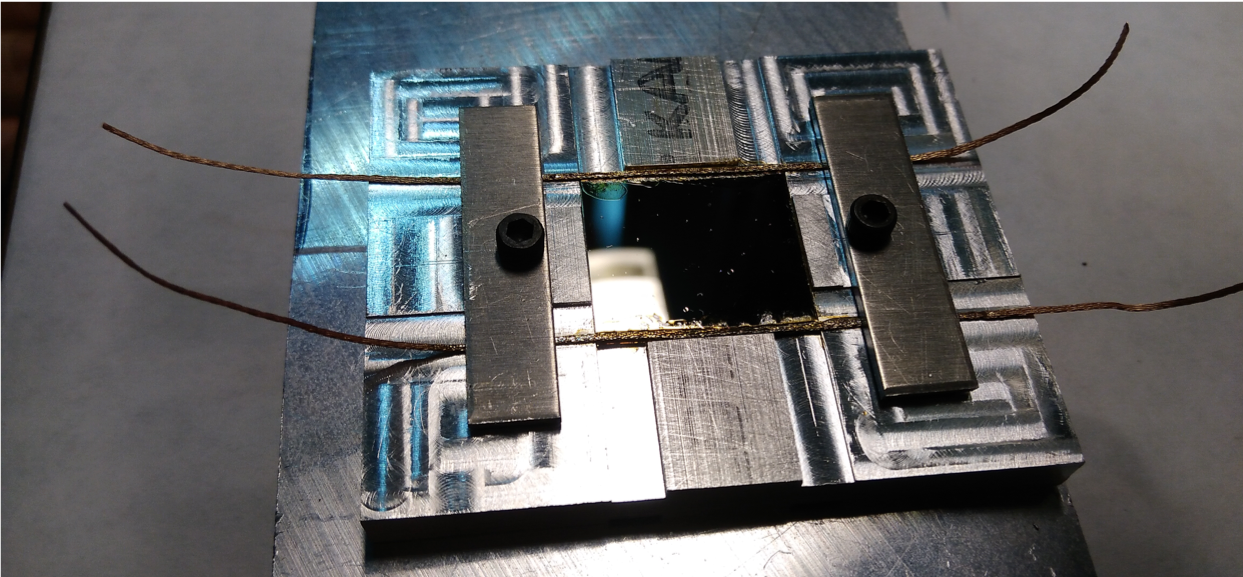

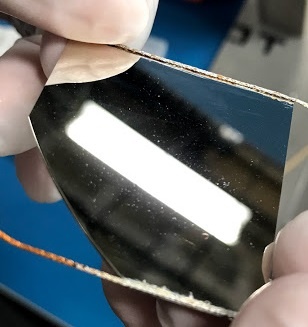

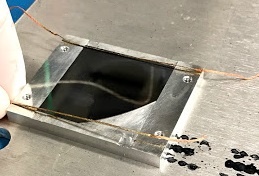

- Once complete the heater with the soldered on wicks will look like this:

Timed Process for mass implementation

Hot plate [10 mins to heat up + 10 mins to stabilize]

Turn on high setting.

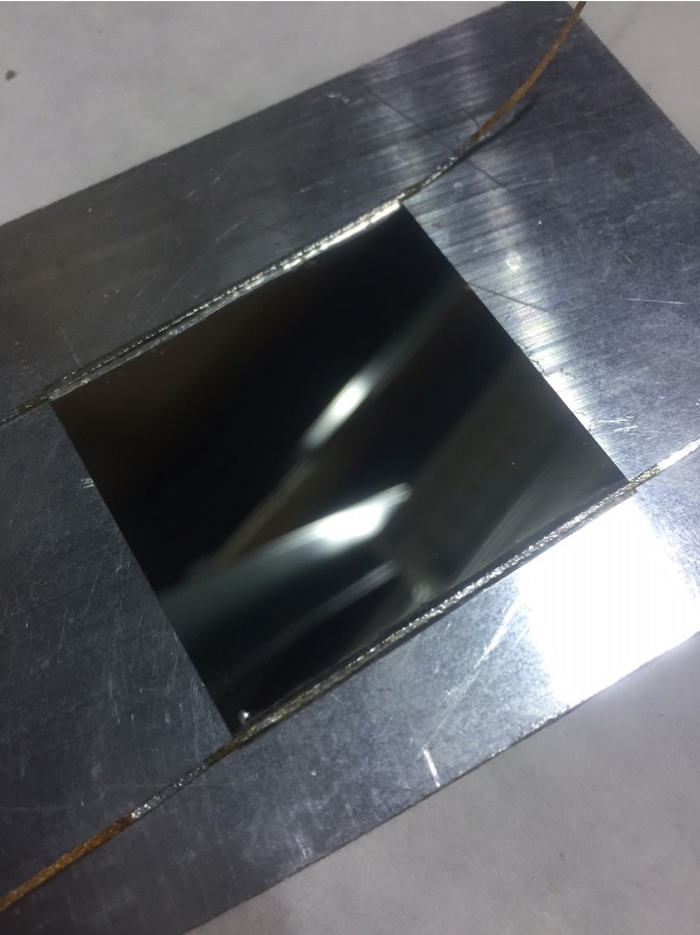

Attach the thermal sensor to the aluminum rectangle ( below the washer)

Place the rectangle on the hot plate - make sure the wires don't bend and the electrical tape doesn't touch the aluminum.

In 10 mins check the temperature and if ~ 250 ℃ - turn the hot plate to 3.5 and let stabilize (fluctuations of ± 2 ℃)

Fixture setup [4-6 mins]

Clean the fixture ethanol

Lightly screw in the rectangles to the fixture

Cut the solder wick into ~8cm lengths

Set initial wire positions

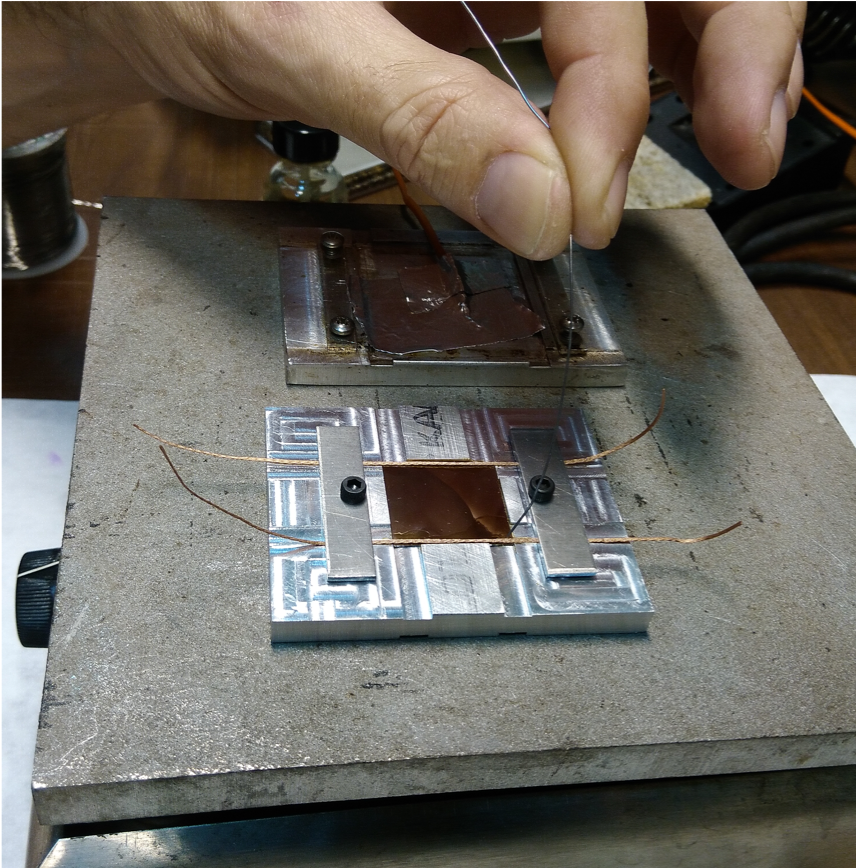

Place the heater in the fixture in the right orientation (using a vacuum pen?)

Tighten the screws making sure the wires are in the right position

Clean the heaters with ethanol

Soldering [5 mins + 6 mins - actual soldering ]

Check the temperature ~ 245 ℃

Using 2 pliers place the fixture with the heaters on the hot plate

Wait ~4 mins for the fixture to come to the right temperature (it smells funky and smokes a bit)

Using the <0.02” diameter solder perform the actual soldering - be careful not to over solder

Clean up [15 mins]

Pick up the fixture with 2 pliers and place on the aluminum sheet

Wait 2 mins for the fixture to cool down

Use ethanol to clean up residue (napkins and Q-tips)

Undo the screws and rectangles

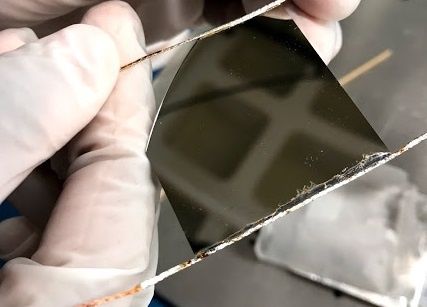

Remove the heater carefully (maybe vacuum pen will help here?) Sometimes the soldering makes the heaters stick to the fixture.

Place the heater in the wax cover and measure the resistance

Clean the fixture again to get it ready for the next heater.

Issues/Suggestions

How to avoid over soldering? Practice?

Speckles on the heaters after soldering - What are they?

Maybe some kind of support for Tan?

How to label the heaters to record the resistance measurements? Mark the wax paper

Tests Performed

Test 1: May 2nd (?) (Successful)

(Aidan)

Test 2: May 13th (Successful)

Resistance - 3.4 ohms

Issues -

- Speckling on the heater surface - Remained even after cleaning the surface with Alcohol - Maybe the flux spluttering and then baking on the heater surface

- Over Soldering - We requested Tan to use lesser solder in the process. Could also be because there was a small gap between the wick and the heater surface causing the solder to flow.

Test 3: May 14th (Not successful)

The wick just came off the heater without any force

Test 4: May 15th (Not successful) - Re-did the same heater as the above

same issue - Wick just came off the heater