...

- The Caladium stage readout storm from Saturday was resolved by Doug McCormick. The solution was to just power cycle the stage control box. Sometime rebooting the IOC can help also but that was already tried by guessing on Saturday which didn't work. Other than physically unplug the stage power, one can also do this power cycle by remote control from AC Power->SCS3: B061 Tunnel->Bank 3 chan 23 "beckhoff 26".

- Doug turned the Caladium Y-fine stage drive current from 1A to the max of 3A and verified it can now drive ~50kg.

- We reinstalled the small rotation stage with the double chip FEI4B module 93-04-03 and verified the fine stage drives are now all functioning.

- Worked with Mike Dunning on the two HV monitoring ADC lines. The Vmon line is moved from KL3132 to KL 3404 together with the Imon so that KL3404 now has Chan01=HV-Imon; Chan02==HV-Vmon. Also adjusted the scaling factor for Vmon so that it has a slope=1.12 which gave identical reading between the Voltmeter and EPICS physical value for Vmon=-618mV (HV=-618V). At very low Vset the two differ somewhat probably due to some small offset but this is unimportant for higher HV range.

- Powered on the double-chip module with LV=1.5V; HV=-80V. Tried calibration but initially chan-0 not working but chan-1 worked. Swapped data cables between the two channels and then both channels worked (bad connection the first time?).

- Tried to bring up full EUDAQ readout MIMOSA DAQ panel got "ErrorConfig Socket" stuck red. Repeated normal startup sequence could not clear it. Resorted to go in the NI windows command line with a shutdown -r to reboot. Upon restart, the error cleared and everything back to running state. There should be a hardware reset for MIMOSA somewhere that shouldn't need to reboot the crate ?

...

- When Rebecca arrived we installed the sensor on the rotation stage spacer were installed to allow beam to travel between metal grating on the rotation stage and the sensor. There are issues with available holes in the setup so the sensor can be installed. We ended up aligning it in the short pixel direction.

- We ran calibGui with the LBNL_tungsten config

- Our first beam of the afternoon ~13:00 - 14:00 we had low particle rates (around 5) and asked MCC to increase it. They opened one of the collimators allowing more particles through and we ended up with around (30). It was easy to align the sensor to be in the center of the beam using the remote control of the stage

- At 17:59 before beam time, the channel one voltage and current read: 1.5v 0.29A and channel two: 1.19V 0.035A

- We he had beam time by 18:06 with ~500 particles per shot according to mimosa. The alignment looked pretty center, but we quickly lost triggers from the DUT system. Probably the high particle rate caused the system to crash. We had multiple errors with RCE: pgp not responding, so RCE had to be restarted a couple of times

- We asked MCC to reduce the particle rate and we got to around 40, but this was still too high to be able to differentiate tracks. The high number of hits was also due to the particle shower from the tungsten. We further reduced it to ~4 particles per shot, according to the telescope but got very little hits. Due to rotation (around 7.5 degrees) the surface area of the DUT is small, and if the collimator was opened was opened to increase particle rate then the hit rate would be decreased. Finally we increased to around 40 at 18:51. Another pgp error for rce kept us from taking run data.

- method of dealing with rce failure:

reboot HSIO -r 0

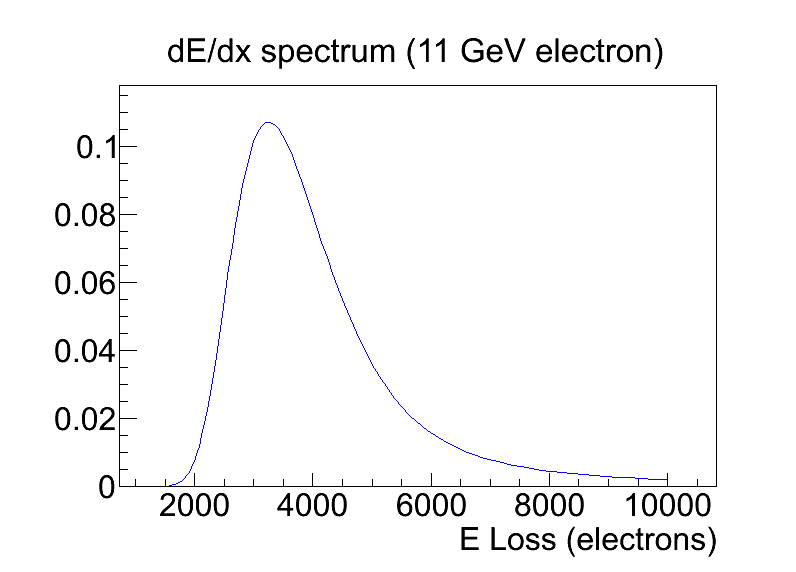

rceOfflineProducer -r 0 -d 172.27.100.8 - Run 346 | 19:00: the module is biased ~17V, the tuning file is config_standard_208.cfd which corresponds to 200 electrons at 12k electrons at ToT=10. We are getting very long clusters between 18-25 pixels, but they are broken so 4+ missing hits per pixel.