...

- Moved lab setup of cold box with LUB2 to ESA.

- The dry CO2 chamber is reversed from May to be on the corridor side while electrical connections from rack side. Beam entering from the back of the FE-I4A card.

- LV VDD=1.5V. I=0.33A after config.

- One temperature probe (Ts) taped to the Cu cooling tape tail from the DUT, the other temperature probe (Tg) in cold gas.

- Leakage current high initially but temperature was just -10C. 2nd access raised HV to 800V leakage current 830uA at Ts= -23C.

- After ensuring only ch=0 for RCE activated in readout, calibration ran, but threshold distribution is broad. Returned and got a quite decent RMS now. Saved to LUB2/config_rad_np_0_335: 1500e threshold, 8000e=10 for TOT.

- Made EUDAQ config SLAC_1dut_rad_FEI4A.conf

- Alignment was still tricky. Fine-Y adjustments not holding up the position. Any adjustment would trigger a long sag. Mike/Keith both thought the motor holding current may be too low. Will be looked at tomorrow before 9am by TestFac.

- Because DUT X/Y transposed, we cannot see correlations any more between MIMOSA and DUT as correlation only plots X vs 'X'.

- Horizontally we would like to move Fine-X towards +X (rack wall) by ~1cm to align with EUDET but that reached limit and cold box cable exit is touching Caladium plane frame.

- Requested access ~4:45pm. Put a ~2cm block spacer in the cold box to move DUT towards -x to recenter better in X wrt Caladium and space out the cable exit from Caladium. Also jacked up the DUT box by hand to be close to center in Y. Topped off dry ice.

- MCC notified us that LCLS MFX requested change of beam energy up to 14 GeV (but secondary always 11 GeV) which will affect our rate for a while. After reconfigure the beam spot shape changed completely with more definite edge and more uniform. Previous beam spot had a sharp hot spot of on the top right corner and more diffused spread below that.

- 6:45pm first serious data run 294. HV=800V, leakage current 200uA. Ts=-34C, Tg=-29C. ~350 hits/MIMOSA, 150 hits/evt in APIX. DUT beam window: Local X=40-75 which is 35 pixel ~8.5mm; Local Y=30-330 which is 300 pixels ~15mm. MIMOSA beam window X=200-1000 also ~15mm; Y=20-460, also 8mm.

- Noticed some 'scars' on the DUT which are straps of area with clearly lower hit density than neighboring areas.

- Ended a good run 294 to request lower rate. MCC had no clear recipe to reduce rate other than collimating to smaller beam size which doesn't really help us as it is the hit density that matters. They are trying to reach Toni Smith for advise. Ryan tried to tune this from upstream adjustments and succeeded to bring the rate down to 30 hits/shot at DUT with relatively small change in beam spot shape. We needed to make a few mm adjustments to keep both MIMOSA and DUT beam window fully contained.

- 8:34pm 2nd run 299 with DUT hit rate ~30/frame. Temperature climbing back up Ts=-32C, Tg=-27C. Leakage current 250uA. MIMOSA beam window X=150-700 (10mm) and Y=full span 0-570 and perhaps a bit more (11mm). DUT window 'X'=30-74 (11mm), 'Y'=40-260 (11mm) a bit trapezoidal.

- 9:06pm started a new run 300 when last run reached 10K event limit. Exactly same condition. Ended 21:42.

...

Operations team: Veronica WallengenWallangen, Su Dong

- Cold box temperature still at -45C after long overnight warm up.

- Started with swapping in LUB1, placed at the 73 degree tilt . Also noticed Caladium is placed rather high which appeared to be due to the stuck DUT stage at slightly low fine Y so that Caladium is used to lift the DUT up into the beamline. We dropped two piece of metal slabs of ~1cm thick to lift the DUT up within the box. This bear made it to a partial overlap of top of DUT and bottom of MIMOSA. Much of the day was spent on locating the DUT overlap with Caladium and beam. Initial manual alignment by eye should have been done more rigorously. Readout errors. Replaced data ethernet cable from Lupe's to the black ESA commercial cable. No difference. Touched the LV cable inside box to reduce sharp bend with better loop. This recovered readout (or the LV power up sequence made the difference? Martin's theory was that one should hold off plugging in the actual LV to frontend after the PSU setting settled). in the double dry N2 chamber mode. However, the facing to beam is opposite of LUB1 to get easier looping of cables. In the tilted position, LUB2 had cable connectors upstream and beam entering via backside of the test card. LUB1 is mounted with cable connectors at downstream and beam entering the test card from the front.

- Also noticed Caladium is placed rather high which appeared to be due to the stuck DUT stage at slightly low fine Y so that Caladium is used to lift the DUT up into the beamline. We dropped two piece of metal slabs of ~1cm thick to lift the DUT up within the box. This bear made it to a partial overlap of top of DUT and bottom of MIMOSA. Much of the day was spent on locating the DUT overlap with Caladium and beam. Initial manual alignment by eye should have been done more rigorously.

- Readout errors. Replaced data ethernet cable from Lupe's to the black ESA commercial cable. No difference. Touched the LV cable inside box to reduce sharp bend with better loop. This recovered readout (or the LV power up sequence made the difference? Martin's theory was that one should hold off plugging in the actual LV to frontend after the PSU setting settled).

- All calibrations for LUB1 and LUB2 were stored in the moduleconfigs/LUB2 config directory. There was no known 1500e tune for LUB1. After getting some suggestions from Ben on the phone we picked config_rad_np_0__254.cfg which was a LUB1 tune of 2000e tune for 8000e@10 TOT. Briefly trying the cfg for threshold calibration which showed quite narrow threshold distributions for the ESA LUB1 setup. Running other cfg based on LUB2 gave much broader threshold dispersions. created the EUDAQ configuration SLAC_1dut_rad_LUb1.conf with this setting as running config for today.

- During the test runs with LUB1 to search for DUT position, at some point we noticed the occasional in time DUT signals appeared at time sample=1 instead of the usual center of 8. We even changed the config turgidly for it to move the data to time sample=8, but later on the peak shifted to ~15 so we returned the setup to the original form and DUT data time sample is back to 8.

- 19:06 started run 333 with LUB1 @ 1.1KV HV (leakage current 170uA) and DUT pixel rate ~70, but MIMOSA is only capturing the top half of the beam spot to allow the beam just catching the bottom part of the DUT. DUT beam window 'X'=5-30; 'Y' almost full span. MIMOSA beam window X=100-700; Y=0-160 (clipped at Y=0).

- 19:44 another run 335 with the same conditions.

- Attempted another 1500e tune for LUB1 following Martin's suggestion to skip the Noise Scan at step 13 but the process stumbled at step 16 for Noise Scan again, exactly the same way. So have to continue with the 2000e config.

- Raise HV to 1.2KV and every still looked benign with leakage current ~180uA.

- Just as we started to config, some major glitch took place ~9:40pm and entire Caladium stage control/ADC/temperature etc in an error state that never self-recovered. All temperature, HV readings became unavailable and Caladium stage also became uncontrollable.

- We did not realize the seriousness of the Caladium control loss and went ahead lifted out the DUT and turned it to 90 degrees to beam after quite a bit if trouble.

- Reconnecting DUT also had trouble with readout error again. Upon playing with the LV power on sequence, it was noticed that the BK precision LV PSU went into a spontaneous chaos mode with displays flickering and numbers fluctuating and even partial screen blackout. This may well be the source the various readout flakiness.

- After waiting for 1-2 hours, the HV current went down enough to allow HV setting to go up to ~700V but current ~500 uA still fluctuating a lot and couldn't settle. Don't know what temperature this was. Dry ice is rather low and doesn't look like temperature can help this much from here on.

- Too many things telling us it's time to quit: Flaky LV PSU and readout errors, unsettling HV, broken Caladium drive and display, and we are out of dry ice. Dismounted the cold box from Caladium and placed the LUB1 in the ESA freezer together with LUB2.

- Concluded the day with just two good tilted runs with LUB1 @ 1.1KV.

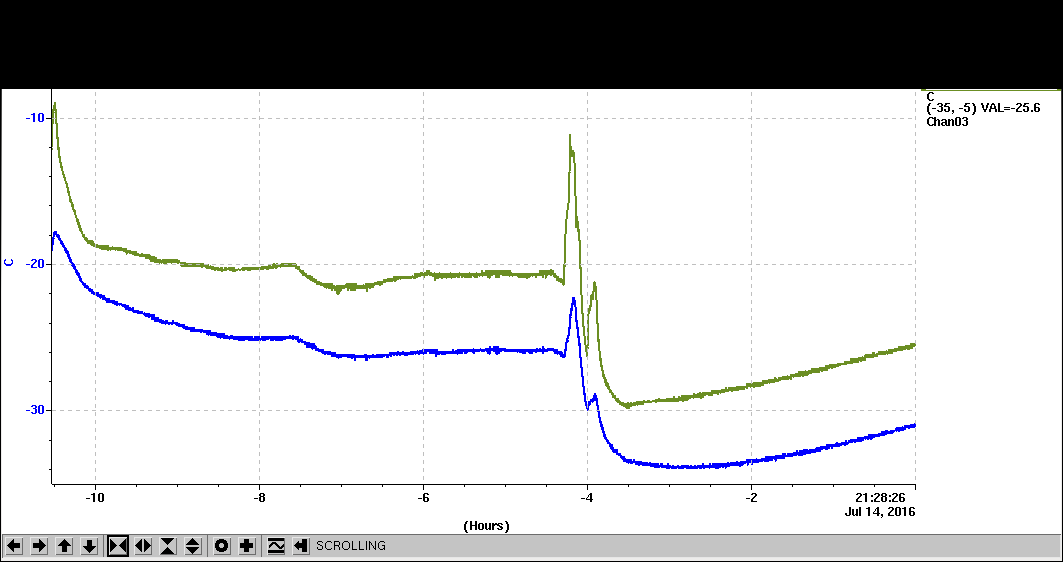

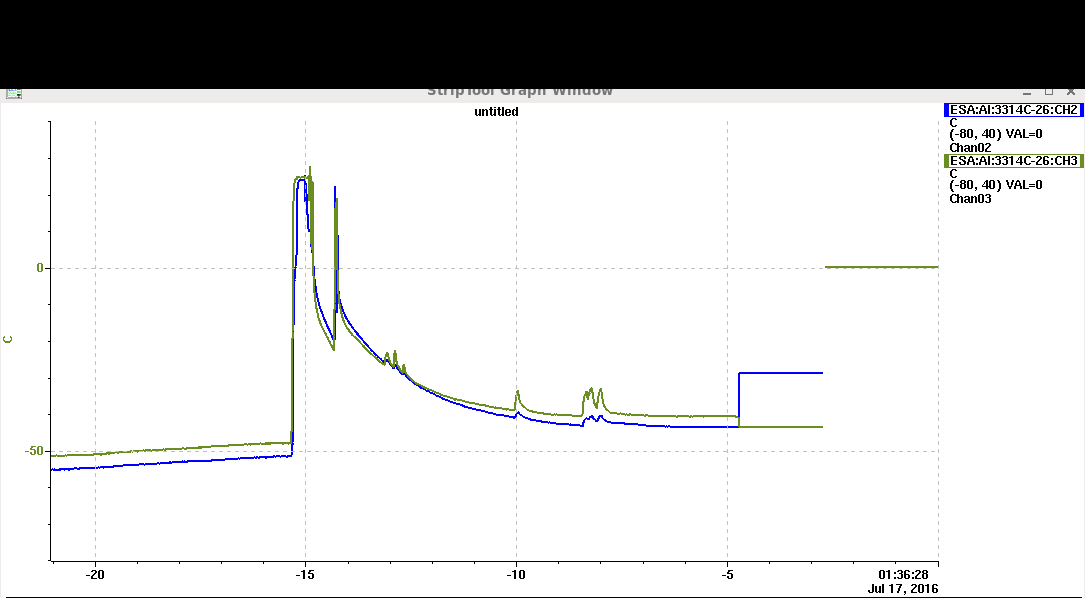

- The temperature time history below for July/16 showing initial blue=probe tied to DUT Cu tape, green-cold box gas. The step at t=-5 hours is the big glitch that took out the Caladium drive/display.

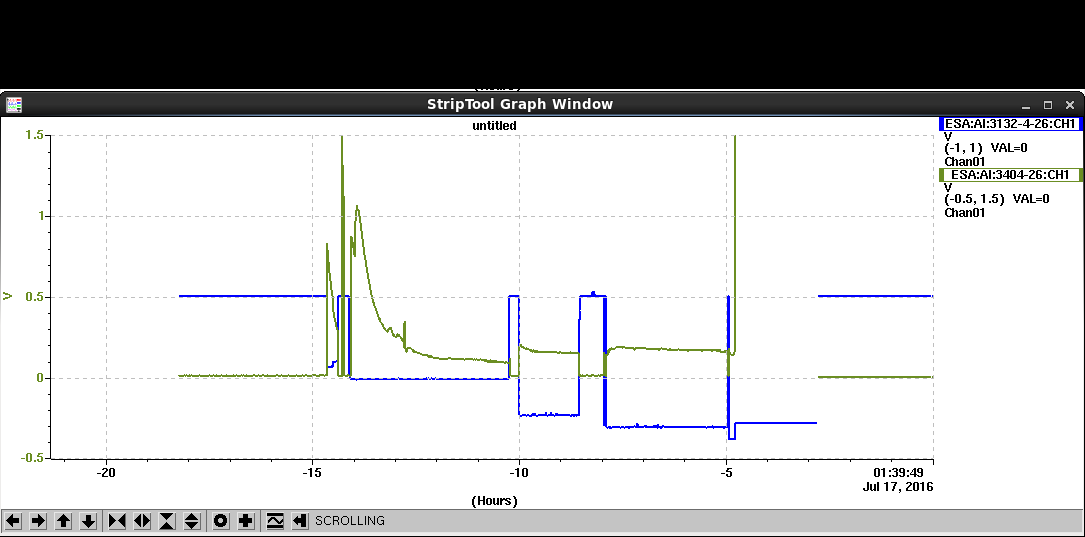

- The newly installed Caladium ADC for the HV Vset and Imon: The green leakage current mon is roughly calibrated to the HV module's LEMO mon socket claimed of 1V=1mA. The blue Vset calibration was a bit strange which showed -0.75V for -1KV. Glitch at -5h made Caladium stage control into permanent error state, all values after that were invalid.