This procedure is written for the LPL operation after the 100J upgrade. The LPL upgrade changed the beam size and relay imaging after the 1" CD amplifier. The upgraded setup employed new irises and new camera imagers for alignment checks with higher precision. The new procedure includes the hardware turn-on, the software turn-on, a new alignment routine (using imagers and irises), commands for SHG and HWP optimization, and recipes for new pulse shapes.

TO DO

- add a capability to put by default 'dither' to Yes

- press Y after the dither step again

- Add detailed/"expert" alignment steps as a link

- press Y until happy with the shape

- after SHG optimization, if you want to check Scope B enable 10 Hz on nsSlicer

Brief overview of LSS panel

Figure 0: Shutter S4 releases the output of the YFE. Transport shutter T3 is to allow the LPL into the chamber and T4 is to allow the Visar into the chamber. (Red: open, Green: closed)

Turn on hardware

- Set hutch to “Class 1”, or “Class 4 Glass Laser”, or “Class 4 Dual Laser”, or “Class 4 Split Mode

- At the LSS display, badge in and open Shutter S4, and press the “Press to reset interlocks"

Turn on four chillers. Note that the chillers will not be at their set operating temperature for at least 15 minutes after turn on. The YFE laser output power will be lower than normal operating power until the chiller temperatures have reached their set values.

Figure 1: 4 chillers

Turn on four TDK Lambda power supplies. Power switch to “1” .Press the tiny “out” button at each of the 4 supplies.

Figure 2: TDK Lambda power supplies

- Turn on six eDrives: keys and power buttons

Figure 3: six eDrives

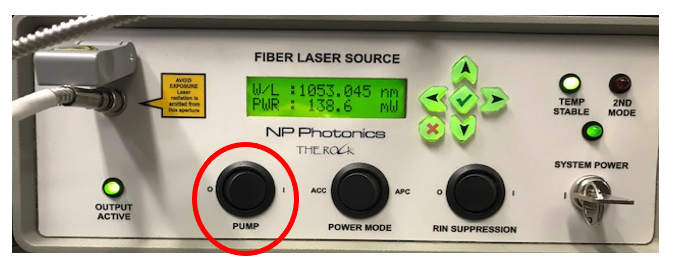

- Switch on NP Photonics Seed Laser: toggle the “pump” switch from position 0 to 1. You will see PWR ramp up to around 140mW.

Figure 4: NP Photonics seed laser

Turn on YFE

Do the following on the terminal:

- ssh mec-laser

- mecpython

- import meclas

- meclas.YFE.On()

- There will be a series of events that will happen to stabilize the seed laser prior to turning on the current to the YFE laser heads. If and when all conditions are stabilized, a series of audible ringing chimes can be heard coming from the e drives. It can take anywhere from 10's of seconds to several minutes for the conditions to be sufficient that the e drives can be turned on. This is the indication that the YFE laser is operating the that a beam is present at the LSS shutter S4, if LSS shutter S4 is closed. If LSS shutter S4 was opened as described above in Turn On Hardware section, the the beam will be present through the LPL amplifiers and SHG crystals.

Confirm YFE operation before firing shots

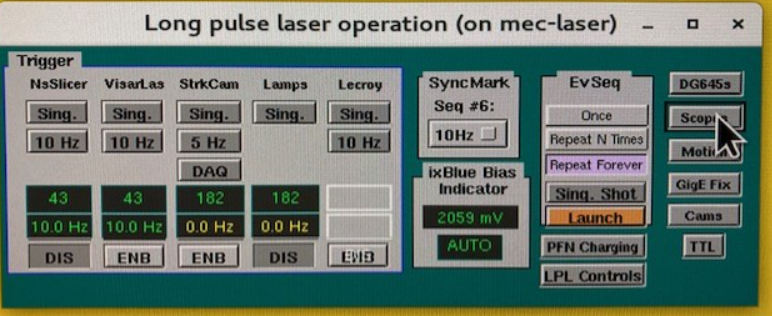

- Open Long pulse laser operation from MEC home

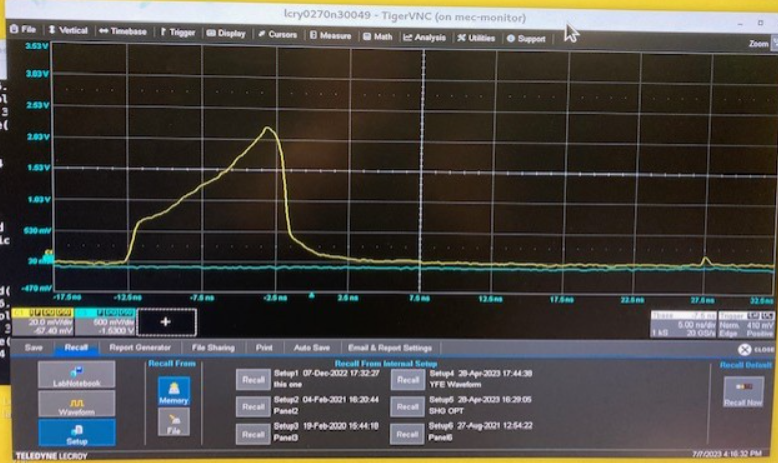

- Open Lecroy A scope to monitor 10Hz pulse shape

- If trace is not present on Lecroy A, make sure that 10Hz operation is enabled.

- If the trace is not present, confirm shutter 4 on the LSS is on

- If the trace is still not present, it may be necessary to cycle meclas.YFE.Off() and meclas.YFE.On() until the trace is present.

Load the waveform recipe and shape the waveform

meclas.LPL.psmenu(): this command gives you a list of recipes to choose from (Fig. 5). Then type in the recipe from the menu list, for example, l56 == "U10ns00gradE100J"

- meclas.LPL.psefc10Hz(numIterQ=150): this command will shape the 10Hz pulse until it reaches the target waveform. You can set numIterQ = x to run x times of iteration. In figure 6, the upper left shows all the parameters you can set. The right plot shows the 10Hz pulse (blue) and the target waveform (red). For more detail please check how to make a new recipe.

Figure 5: choose the pulse recipe: use commend "meclas.LPL.psmenu()" Figure 6: shape the 10Hz pulse as designed.

Note: If meclas.LPL.psefc10Hz() is run, then the default number of iterations is set at 50. Running this command consecutively three times will provide the same results as meclas.LPL.psefc10Hz(numIterQ=150).

- It may be necessary to repeat meclas.LPL.psefc10Hz(numIterQ=150) if the blue trace is not fit well to the red trace.

- Confirm YFE operation before firing shots

Confirm SHG crystal angles are optimized

- command meclas.LPL.SHG_opt() will run four SHG crystal rotation stages and find the maximum one by one. It is recommended that meclas.LPL.SHG_opt() is run at least once per day, preferably before the 1st day of the shot is taken.

Optimize HWP

- Command meclas.HWP.HWP_opt() will set all four half-wave plates at zero degrees (zero energy trim). No need to run this if no changes to HWP's were made in effort to "trim" energy.

Open the beam monitor cameras -minimum cameras needed for spatial beam quality check

There are 2 cameras in the upgraded LPL layout used to monitor the East and West beams delivered to the TC. the new camview can be opened in mechome [detectors>view-long pulse Laser Cams> dropdown (figure below 1)]. For camview detail please check New Camview Feature

For operation and monitoring purposes only LPL_100J_3, LPL_100J_4, are needed to open. For full alignment, using these 6 cameras is recommended. These imagers locations and descriptions are as followed (figure below 2).

- LPL_100J_3: the imager looking at combined east 527nm (IJ+GH output)

- LPL_100J_4: the imager looking at combined west 527nm (AB+EF output)

It will be necessary to take an amplified shot to check the integrity of the 527nm beams from the combined legs on the East beam and the combined legs on the West beam because there are ND filters in front of both Cams 3 and 4 that are set to attenuate the full amplified energy from all beam legs. If the 10Hz beam quality through the amplifier legs is to be viewed on either of these two cameras, it will be necessary to open the doors, remove the filter assy in front of both Cam3 and Cam4 cameras, and trigger the cameras at 10Hz.

Figure 7. Open Long Pulse Laser Camview

Figure 8. Long pulse laser cameras and irises layout

Fire a shot

- Make sure the final shutter, T3a and T3b, are closed. If it is open, make sure things are properly blocked inside the target chamber.

- check event sequence configuration: play status "stopped" in case the lamps got misfired.

- change camera trigger to "single shot": in MEC Home> EVR > New MEC LAS EVR > Front Panel B change to 182 (single shot) from 43 (10Hz)

- change Ns Slicer and Lamps to single shot: Long pulse laser operation> click Single buttons on NsSlicer and Lamps

- Charge: MEC:PFN> click "stop", "Stand By", "Ready" and "Charge"

- Fire: click "single shot"

- run postshot: meclas.LPL.pspostshot(save_flag = True, display = True), it shows a plot and energy output.

- or show energy meter: meclas.EMeters.EGall()

Figure 10. left: Event Code Sequence, Middle: new MEC LAS EVR, the camera trigger is at cha 11 (Front Panel B), right: Long pulse laser operation and MEC:PFN

Figure 11. upper left: 10Hz YFE pulse shape (blue) and designed pulse shape (red). upper right: combined 100J shape. left: camview "LPL_100J_3" and "LPL_100J_4" showing single beam profiles, right: run "LPL.pspostshot()".